Kaveri & Aero-Engine: News & Discussion

-

Drishyaman

- BRFite

- Posts: 279

- Joined: 15 Aug 2010 18:52

- Location: Originally Silchar, Assam

Re: Kaveri & aero-engine discussion

The frontline Jet Fighter engines India have been manufacturing under license or would have the license to manufacture with some amount of TOT in India from all over the world.

Russia - AL-31FP, RD-33

United States - GE F414

In addition we are going to have the French in Snecma – GTRE JV. They are going to be the consultant for us and will probably allow us to use the M88 – Eco core.

Now, if I do a wishful thinking here, if Typhoon gets selected as MMRCA, as per the offset clause we will probably be manufacturing the EJ200 also in India with some amount of TOT as well.

And it is not that we do not know how to make a Jet Engine as we have made a work able engine which is developing a respectable 75 KN thrust. And it is just that we need to increase the thrust by another 20 KN.

The point that I am trying to make by telling such a long story is that probably there is no other country who is manufacturing such wide variety of frontline Jet Engines from all over the world. As someone has coined the term “Chinese Therapy” in a different thread, can we use some “Chinese Therapy” to solve our problem. Do we really need another 4-5 yrs to increase the thrust by 20 KN?

Russia - AL-31FP, RD-33

United States - GE F414

In addition we are going to have the French in Snecma – GTRE JV. They are going to be the consultant for us and will probably allow us to use the M88 – Eco core.

Now, if I do a wishful thinking here, if Typhoon gets selected as MMRCA, as per the offset clause we will probably be manufacturing the EJ200 also in India with some amount of TOT as well.

And it is not that we do not know how to make a Jet Engine as we have made a work able engine which is developing a respectable 75 KN thrust. And it is just that we need to increase the thrust by another 20 KN.

The point that I am trying to make by telling such a long story is that probably there is no other country who is manufacturing such wide variety of frontline Jet Engines from all over the world. As someone has coined the term “Chinese Therapy” in a different thread, can we use some “Chinese Therapy” to solve our problem. Do we really need another 4-5 yrs to increase the thrust by 20 KN?

Re: Kaveri & aero-engine discussion

Tejas to soar high at AeroIndia 2011

Data point:

Data point:

"We plan to use the F404 engines to power the first 20 aircraft the IAF has ordered and the enhanced GE-414 engines for the second order of 20 aircraft, which will be the Mark-2 version, while Kaveri will be used for the trainer and naval variants and the air force variant when they are upgraded a decade later," Subramanyam pointed out

Re: Kaveri & aero-engine discussion

NRao wrote:Tejas to soar high at AeroIndia 2011

Data point:

"We plan to use the F404 engines to power the first 20 aircraft the IAF has ordered and the enhanced GE-414 engines for the second order of 20 aircraft, which will be the Mark-2 version, while Kaveri will be used for the trainer and naval variants and the air force variant when they are upgraded a decade later," Subramanyam pointed out

GE F414 Engines Selected to Power India Light Combat Aircraft Program

--LYNN, MASSACHUSETTS -- India's Aeronautical Development Agency (ADA) has selected 99 F414 GE fighter jet engines to power the Mk II version of the Tejas Light Combat Aircraft (LCA) for the Indian Air Force.

John Flannery, President & CEO, GE India said, "The LCA selection is a big step forward for GE and demonstrates our strong commitment to India. GE Aviation will supply the initial batch of F414-GE-INS6 engines and the rest will be manufactured in India under transfer of technology arrangement."

The F414-GE-INS6 is the highest-thrust F414 model and includes state-of-the-art technology to meet India's demanding Air Force and Naval requirements. Technical advances include a Full Authority Digital Electronic Control (FADEC) and added single-engine safety features.

"We are extremely pleased with the ADA's decision and are confident India's technical expertise will help enhance the F414-powered LCA's mission superiority well into the 21st century," said Tony Mathis, general manager of Lynn Military Systems programs at GE Aviation.

This selection follows earlier orders of 24 F404 GE engines in 2007, plus an initial 2004 purchase of 17 F404 engines to power a limited series of operational production aircraft and naval prototypes.

With more than one million flight hours, the F414 engine continues to exceed United States Navy goals for reliability and time on wing. To date, more than 1,000 F414 engines have been delivered, supporting more than 415 aircraft in the fleet.

GE Aviation, an operating unit of GE (NYSE: GE), is a world-leading provider of jet and turboprop engines, components and integrated systems for commercial, military, business and general aviation aircraft. GE Aviation has a global service network to support these offerings.

Re: Kaveri & aero-engine discussion

ge404 has long 4000 hour life this means it would not be needed to be changed before 15-20 years but it might need overhaul for sureNRao wrote:Tejas to soar high at AeroIndia 2011

Data point:

"We plan to use the F404 engines to power the first 20 aircraft the IAF has ordered and the enhanced GE-414 engines for the second order of 20 aircraft, which will be the Mark-2 version, while Kaveri will be used for the trainer and naval variants and the air force variant when they are upgraded a decade later," Subramanyam pointed out

but it also depend on the life of tejas airframe which should be 4000 hours conservative approach.

Re: Kaveri & aero-engine discussion

F404-GE-IN20 Engines Ordered for India Light Combat Aircraft

--BANGALORE, INDIA -- Hindustan Aeronautics Limited (HAL) has ordered an additional 24 F404-GE-IN20 afterburning engines to power the first operational squadron of Tejas fighter aircraft for the Indian Air Force. Value of the order is in excess of $100 million and follows an initial 2004 purchase of 17 F404-GE-IN20 engines to power a limited series of operational production aircraft and naval prototypes.

Earlier this year, the F404-GE-IN20 was trial-installed in Light Combat Aircraft (LCA) as part of final evaluations toward flight-testing, scheduled for mid-2007. The F404-IN-20 engine has generated more than 19,000 pounds (85 kN) uninstalled thrust and has completed 330 hours of Accelerated Mission testing, which is the equivalent of 1,000 hours of flight operation.

The F404-GE-IN20 succeeds F404-F2J3 development engines used for nearly 600 flights, cumulatively covering eight engines.

Based on the F404-GE-402, the F404-GE-IN20 is the highest rated F404 model and includes a higher-flow fan, increased thrust, a Full Authority Digital Electronic Control (FADEC) system, single-crystal turbine blades and a variety of single-engine features.

The F404 fighter engine family is one of the most successful in military aviation history. More than 4,000 F404 engines power a number of combat aircraft flown by the United States Air Force, Navy and Marine Corps, plus countries throughout Europe, Asia and Africa.

GE Aviation, an operating unit of General Electric Company (NYSE: GE), is one of the world's leading manufacturers of jet engines for civil and military aircraft. GE also is a world-leading provider of maintenance and support services for jet engines.

Re: Kaveri & aero-engine discussion

I would not put too much thought into LCA-Kaveri combo. I believe the prize for Kaveri will be the AMCA, the true Indian air craft.

Re: Kaveri & aero-engine discussion

Gurus please comment..........

Re: Kaveri & aero-engine discussion

kaveri on tejas is essential to use it for fighter service and work out any issues long before it can considered a serious contender for AMCA engine bay.

Re: Kaveri & aero-engine discussion

Second set of flight trials in March/April. Then onto the LCA if successful. But only for proving that it can do it. Tejas will be with F404/F414 onlee... :-(

Re: Kaveri & aero-engine discussion

that's expected. the kaveri-1 is more a TD now. the real target is the AMCA. but they should really rename the snecma kaveri JV engine, otherwise we will be hearing "they are working on it since 1983".

kaveri is very controversial, as residents of TN and K'taka would agree.

name it torsa perhaps, a fierce hilly river that flows through tibet and bhutan into India.

kaveri is very controversial, as residents of TN and K'taka would agree.

name it torsa perhaps, a fierce hilly river that flows through tibet and bhutan into India.

-

Drishyaman

- BRFite

- Posts: 279

- Joined: 15 Aug 2010 18:52

- Location: Originally Silchar, Assam

Re: Kaveri & aero-engine discussion

OT :Rahul M wrote:name it torsa perhaps, a fierce hilly river that flows through tibet and bhutan into India.

Rahul Ji,

Not sure if you heard of the river called "Barak" it flows through my native place

It’s a perennial river and has got no controversy associated with it. The banks of river "barak" is very fertile.

Re: Kaveri & aero-engine discussion

jani bondhu kintu that name is taken by the missile system.

Re: Kaveri & aero-engine discussion

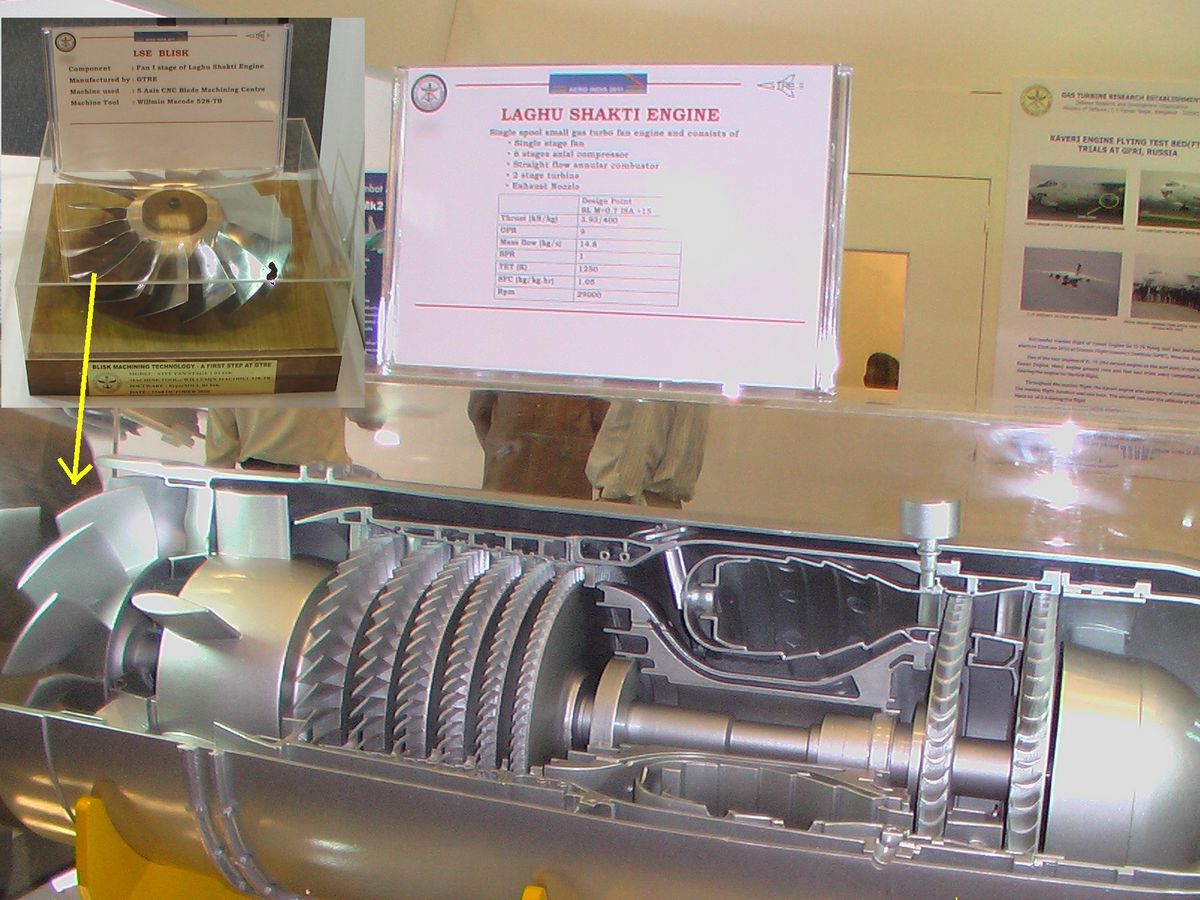

Interesting thing written on the gold plate fitted on the blisk display "BLISK MACHINING TECHNOLOGY A FIRST STEP AT GTRE". Looks like we are finally overcoming the hurdles in the high end aeroengine material manufacturing section.

Re: Kaveri & aero-engine discussion

Not yet.Sagar G wrote:

Interesting thing written on the gold plate fitted on the blisk display "BLISK MACHINING TECHNOLOGY A FIRST STEP AT GTRE". Looks like we are finally overcoming the hurdles in the high end aeroengine material manufacturing section.

1. Those Blisks are for small engines, not for something like a Kaveri.

2. Currently Kaveri uses directionally solidified turbine blades from Snecma

3. Directionally solidified turbine blades from DMRL are undergoing certification. Only after being successfully certified is there any chance to put it into Kaveri

4. Single crystal blades - DMRL can produce lab quantities, say upto 5 sets. Those need to be certified, but that can only come after the DS blades are certified. So long way to go here.

Net, a very long way to go to get somewhere on the materials front.

Re: Kaveri & aero-engine discussion

and after all these testing its another challenge to productionize it and produce it from HAL engine div/other manufacturing units at production rates.

Re: Kaveri & aero-engine discussion

Merlin, that Laghu Shakti turbo fan engine thrust ~400kgf and sfc 1 kg/kg-hr.

Is it for the Nirbhay?

Is it for the Nirbhay?

Re: Kaveri & aero-engine discussion

Awesome info on the BLISK!

make SCB as well so!

make SCB as well so!

Re: Kaveri & aero-engine discussion

25% more powerful and 30% more fuel consumption that the one that powers the Tomahawk.....ramana wrote:Merlin, that Laghu Shakti turbo fan engine thrust ~400kgf and sfc 1 kg/kg-hr.

Is it for the Nirbhay?

Re: Kaveri & aero-engine discussion

AOA! So they have realized the small turbofan grail. We can expect own Predators etc powered by Laghu Shakti. Does in mean blood power!

Re: Kaveri & aero-engine discussion

Williams F112 engine ?

Re: Kaveri & aero-engine discussion

http://forums.bharat-rakshak.com/viewto ... 15#p942115merlin wrote:Not yet.Sagar G wrote:

Interesting thing written on the gold plate fitted on the blisk display "BLISK MACHINING TECHNOLOGY A FIRST STEP AT GTRE". Looks like we are finally overcoming the hurdles in the high end aeroengine material manufacturing section.

1. Those Blisks are for small engines, not for something like a Kaveri.

2. Currently Kaveri uses directionally solidified turbine blades from Snecma

3. Directionally solidified turbine blades from DMRL are undergoing certification. Only after being successfully certified is there any chance to put it into Kaveri

4. Single crystal blades - DMRL can produce lab quantities, say upto 5 sets. Those need to be certified, but that can only come after the DS blades are certified. So long way to go here.

Net, a very long way to go to get somewhere on the materials front.

Kanson wrote:http://livefist.blogspot.com/2010/08/ka ... ingle.html

http://4.bp.blogspot.com/_o_no4M2xEPY/T ... averi4.JPG

2. Titanium Aluminide - Sic composites ( Snecma )

hmm..The Kaveri engine project got revived in 2006 following a joint venture formed between the DRDO and French company, Snecma, an engine-maker, to jointly develop it to fit in the LCA.

http://www.india-defence.com/reports-4526

The slide mentions Snecma connection in developing Titanium Aluminide - SiC composites. Any information on this ?

Anything on the single crystal development and alloys ?

Re: Kaveri & aero-engine discussion

Few newbie questions here -merlin wrote:Not yet.

1. Those Blisks are for small engines, not for something like a Kaveri.

2. Currently Kaveri uses directionally solidified turbine blades from Snecma

3. Directionally solidified turbine blades from DMRL are undergoing certification. Only after being successfully certified is there any chance to put it into Kaveri

4. Single crystal blades - DMRL can produce lab quantities, say upto 5 sets. Those need to be certified, but that can only come after the DS blades are certified. So long way to go here.

Net, a very long way to go to get somewhere on the materials front

what are the steps involved in certification?

why does it take so long?

will there be any major roadblocks scaling of SC and BLISK technologies to the size of Kaveri?

Considering this is one area that we are lacking, I dont understand the lack of urgency in this area..

Re: Kaveri & aero-engine discussion

Thanks Merlin for this informative post. I'am hoping that GTRE would be able to develop a full SDRE Kaveri with all SDRE tech around the end of this decade.merlin wrote:

Not yet.

1. Those Blisks are for small engines, not for something like a Kaveri.

2. Currently Kaveri uses directionally solidified turbine blades from Snecma

3. Directionally solidified turbine blades from DMRL are undergoing certification. Only after being successfully certified is there any chance to put it into Kaveri

4. Single crystal blades - DMRL can produce lab quantities, say upto 5 sets. Those need to be certified, but that can only come after the DS blades are certified. So long way to go here.

Net, a very long way to go to get somewhere on the materials front.

That might be the Snecma supplied SiC blades I doubt they will help us in developing SiC blades, I'm saying so cause our Defence Minister had recently said that "no country how much friendly will give us their A grade tech" moreover didn't France say that any tech transfer in SiC blade tech will take 10 yrs. which I interpret as that the west wants a 10yr technological gap with us in this regard.Kanson wrote:The slide mentions Snecma connection in developing Titanium Aluminide - SiC composites. Any information on this ?

So ultimately we would have to develop all these cutting edge aeroengine materials on our own.

Where do u sense "lack of urgency" ??? And how come show of urgency means the technology being actually developed ???Kailash wrote:Considering this is one area that we are lacking, I dont understand the lack of urgency in this area..

Re: Kaveri & aero-engine discussion

Don't want to sound patronizing, but this area is not child's play. It takes decades to get good in metallurgy and we are far behind the state of the art.Kailash wrote:Few newbie questions here -merlin wrote:Not yet.

1. Those Blisks are for small engines, not for something like a Kaveri.

2. Currently Kaveri uses directionally solidified turbine blades from Snecma

3. Directionally solidified turbine blades from DMRL are undergoing certification. Only after being successfully certified is there any chance to put it into Kaveri

4. Single crystal blades - DMRL can produce lab quantities, say upto 5 sets. Those need to be certified, but that can only come after the DS blades are certified. So long way to go here.

Net, a very long way to go to get somewhere on the materials front

what are the steps involved in certification?

why does it take so long?

will there be any major roadblocks scaling of SC and BLISK technologies to the size of Kaveri?

Considering this is one area that we are lacking, I dont understand the lack of urgency in this area..

I can only answer the last question, to have blisks the size of what is needed for Kaveri means you need to grow crystals that size - not a small ask. So the major roadblock is know-how.

Re: Kaveri & aero-engine discussion

Could be, I didn't ask since I felt I had overstayed my welcome at the GTRE stallramana wrote:Merlin, that Laghu Shakti turbo fan engine thrust ~400kgf and sfc 1 kg/kg-hr.

Is it for the Nirbhay?

The HAL PTAE-7 is also close to the specs of the GTRE one, very close in thrust and SFC and we have had the HAL one since quite some time now. SFC being higher than TFTA ones will only reduce range, power is not a problem.

Re: Kaveri & aero-engine discussion

Laghu means small as in 'Small scale industries' or 'Laghu Udyog'. So literal translation would be 'small power'. 'Lahu' in hindi means blood.ramana wrote:Does in mean blood power!

Cheers....

Re: Kaveri & aero-engine discussion

Thanks merlin.

It would not directly lead to technology development, but can surely accelerate it. More men/money for research would definitely speed up things.how come show of urgency means the technology being actually developed ???

Re: Kaveri & aero-engine discussion

the part of the lecture where Mr. Vlasov speaks about the Kaveri-powered Il-76's maiden flight

http://www.youtube.com/watch?v=7P6BSnTkly8

http://www.youtube.com/watch?v=7P6BSnTkly8

Re: Kaveri & aero-engine discussion

^excellent!

Re: Kaveri & aero-engine discussion

I guess we need to make 'g' silent!

Merlin I thought PTA-7 was turbojet and not a turbo-fan.

Merlin I thought PTA-7 was turbojet and not a turbo-fan.

Re: Kaveri & aero-engine discussion

To develop a true indigenous all Indian latest tech fighter turbine engine requires something like US$ 10 Billion investment which babu will never sanction

Re: Kaveri & aero-engine discussion

Yes it is a turbojet, but thrust levels are only 5% less than Laghu Shakti and has 15% greater SFC. I'm not sure how much difference in range it would make to use PTAE-7 instead of Laghu Shakti. PTAE-7 should be cheaper too.ramana wrote:I guess we need to make 'g' silent!

Merlin I thought PTA-7 was turbojet and not a turbo-fan.

Re: Kaveri & aero-engine discussion

So whats the point of making it a turbo fan if it doesn't give lower sfc? Maybe its tech demo unit.

Laghu Shakti = Small Shakti

Is there a big Shakti? Or is this a prototype for such an engine?

Laghu Shakti = Small Shakti

Is there a big Shakti? Or is this a prototype for such an engine?

Re: Kaveri & aero-engine discussion

merlin wrote:Not yet.Sagar G wrote:

Interesting thing written on the gold plate fitted on the blisk display "BLISK MACHINING TECHNOLOGY A FIRST STEP AT GTRE". Looks like we are finally overcoming the hurdles in the high end aeroengine material manufacturing section.

1. Those Blisks are for small engines, not for something like a Kaveri.

2. Currently Kaveri uses directionally solidified turbine blades from Snecma

3. Directionally solidified turbine blades from DMRL are undergoing certification. Only after being successfully certified is there any chance to put it into Kaveri

4. Single crystal blades - DMRL can produce lab quantities, say upto 5 sets. Those need to be certified, but that can only come after the DS blades are certified. So long way to go here.

Net, a very long way to go to get somewhere on the materials front.

The display only says BLISK MACHINING TECHNOLOGY A FIRST STEP AT GTRE. It does not include casting and heat-treat part. Machining Blisk is indeed a process technology hurdle. It would seem to me that one has to make sure to keep the heat at the tool/work piece interface low otherwise there will be phase changes in those locations leading to grain boundary formation. This will defeat the pupose of single crystal I believe. Indeed a pretty complex issue. One among the several technology hurdles we have to overcome on the way to a truly indigenous Blisk. Congrats to GTRE

Also Merlin mentioned a slow rate of 'production' at the lab. The SC process is inherently very slow. Cannot allow multiple nucleus formations, which will lead to mutli grain boundaries. So slow and controlled cooling. Seems like one solution is to increase the number of stations

disclaimer - these are just my opinions purely based on my experience and knowledge. The above statement could either be swiss cheese or wisconsin cheese.

Re: Kaveri & aero-engine discussion

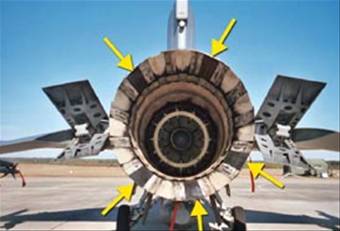

Just curious to know. How?!Kanson wrote: Somehow this pic tells me, we already started adopting Snecma technology or getting guidance from Snecma in designing & maturing our Kaveri engine.

Re: Kaveri & aero-engine discussion

Exhaust temp?

Re: Kaveri & aero-engine discussion

Use of CMC for exhaust nozzle(Check the pic from my previous post). Snecma is the pioneer in using CMC for exhaust nozzle. GE and other majors are learning the ropes only recently.indranilroy wrote:Just curious to know. How?!Kanson wrote: Somehow this pic tells me, we already started adopting Snecma technology or getting guidance from Snecma in designing & maturing our Kaveri engine.

GE plans to introduce CMC for LPT section in the core but from the slides exhibited in Livefist blog, we are working with MMC (Titanium Alluminide - SiC) even for compressor section and one may recall DRML pics of casted Alumina Ceramic BLISK that came in 90s. However, we are not still forthcoming on developments and achievements on Single Crystal and materials design for the hot section. In my assessment, we are working on cutting edge technologies and trying to close the gap in all areas and i believe we judiciously chosen Snecma as the partner for leapfrogging us to future engine material technologies.

Snecma CMC nozzle flaps for PW F100 engine.

http://www.wpafb.af.mil/news/story.asp?id=123116097

9/19/2008 - WRIGHT-PATTERSON AIR FORCE BASE, Ohio -- AFRL engineers are working with industry partners to test the use of ceramic matrix composite (CMC) materials as divergent seals in F100-PW-229 gas turbine engine exhaust nozzles. Geared towards increasing part life, improving reliability, and reducing operating and maintenance costs, the research is focusing on SEPCARBINOX® A500, an advanced self-sealing CMC manufactured by French company Snecma Propulsion Solide (SPS). Thus far, the seals have performed extremely well, and a life-cycle cost analysis is under way to determine whether they should be introduced into the fleet as preferred spares.

CMCs are excellent candidates for replacing the nickel-based superalloys currently used in exhaust nozzle parts, primarily due to their capacity to withstand the high temperatures and severe operational environment for much longer periods of time with minimal changes in structural behavior.

In examining the feasibility of using the A500 seals on the divergent section of the exhaust nozzles, AFRL researchers are addressing a number of key Air Force issues--one of which involves the performance comparison of CMC parts in flight and during engine ground testing. SPS has developed a novel CMC that uses carbon fibers in a sequentially layered carbide matrix produced via chemical vapor infiltration. Because this resultant matrix is self-sealing, it helps protect the carbon fibers from oxidation. The fibers are woven in a multidimensional, ply-to-ply angle interlock pattern to reduce the chance of delamination.

Re: Kaveri & aero-engine discussion

I think my words were confusing. The Laghu Shakti turbofan has 15% lesser SFC and 5% greater thrust compared to the PTAE-7 turbojet. I don't know if that is enough advantage over the turbojet.ramana wrote:So whats the point of making it a turbo fan if it doesn't give lower sfc? Maybe its tech demo unit.

Laghu Shakti = Small Shakti

Is there a big Shakti? Or is this a prototype for such an engine?

Re: Kaveri & aero-engine discussion

Is the schematic diagram about improving K-10 or the so called Snecma-Kaveri?