Kaveri & Aero-Engine: News & Discussion

Re: Kaveri & Aero-Engine: News & Discussion

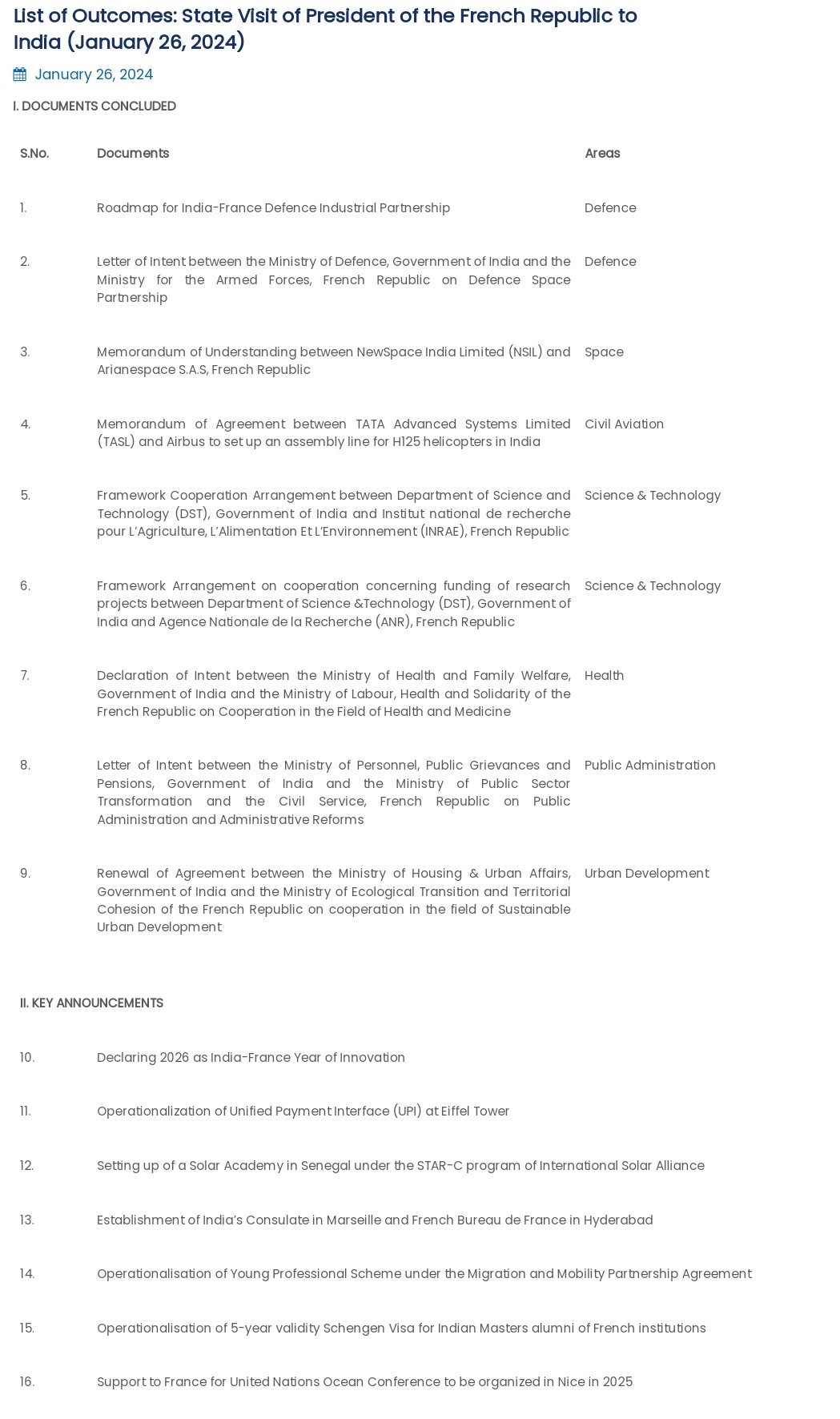

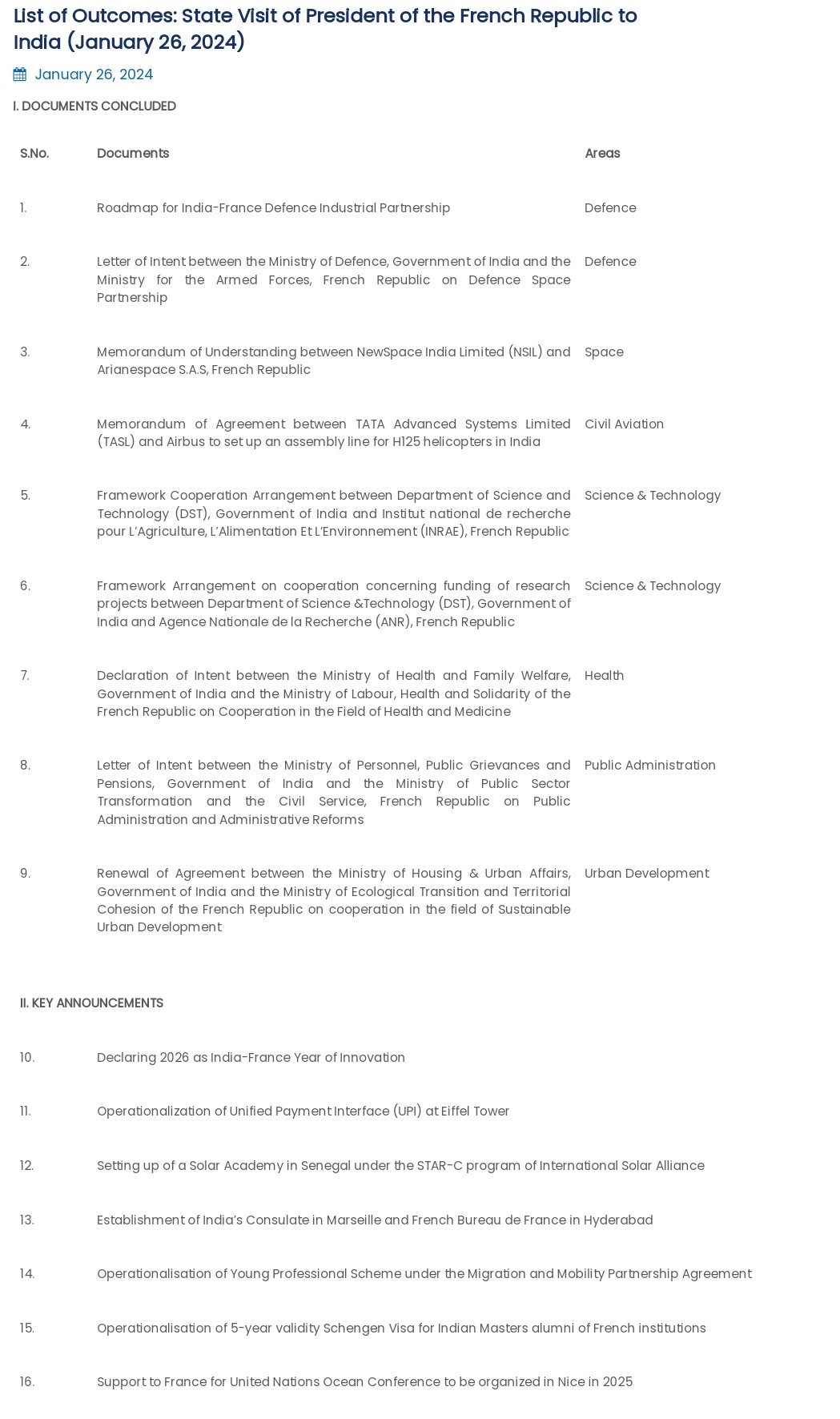

https://x.com/alpha_defense/status/1750 ... 65546?s=20 ---> All I can tell you ---> Industry in France is "Super Excited" about "Modi-Macron" Meet. Deal (?). Roadmap Agreements.

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/Varun55484761/status/1750 ... 93095?s=20 ---> MIDHANI is providing special material developed for the 1st time for Kaveri dry engines, technical know-how from GTRE. Kaveri engines r expected to be ready in around mid 2024 & would go for extensive trials before seeking airworthiness certification.

https://x.com/Varun55484761/status/1750 ... 71721?s=20 ---> Once airworthiness certification happens, government will sanction to mount the engines on one of the LCA Tejas aircraft.

https://x.com/Varun55484761/status/1750 ... 71721?s=20 ---> Once airworthiness certification happens, government will sanction to mount the engines on one of the LCA Tejas aircraft.

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/alpha_defense/status/1750 ... 77744?s=20 ---> The French Government has submitted the roadmap for Jet Engine for the combat aircraft to the Indian MoD.

https://x.com/alpha_defense/status/1750 ... 71667?s=20 --->

* Joint IP (Yes)

* Adaptive Cycle (No)

ADAPTIVE CYCLE ENGINE Explained

https://x.com/alpha_defense/status/1750 ... 71667?s=20 --->

* Joint IP (Yes)

* Adaptive Cycle (No)

ADAPTIVE CYCLE ENGINE Explained

Re: Kaveri & Aero-Engine: News & Discussion

VIDEO: https://x.com/StratNewsGlobal/status/17 ... 18197?s=20 ---> Safran-Shakti Jet Engine Deal

* Subject to ongoing discussions, issue really about arriving at a set of specs that comply with our future requirements

* Not just looking for a manufacturing ToT but to work in actual design phase, metallurgical aspects, etc

* Complex subject, these discussions will continue to take place

* Also part of defence industry roadmap

============================

Someone created an AI generated image of Modi and Macron looking at a jet engine, to symbolize the partnership between the two nations.

https://x.com/Defencematrix1/status/175 ... 91513?s=20 --->

* Subject to ongoing discussions, issue really about arriving at a set of specs that comply with our future requirements

* Not just looking for a manufacturing ToT but to work in actual design phase, metallurgical aspects, etc

* Complex subject, these discussions will continue to take place

* Also part of defence industry roadmap

============================

Someone created an AI generated image of Modi and Macron looking at a jet engine, to symbolize the partnership between the two nations.

https://x.com/Defencematrix1/status/175 ... 91513?s=20 --->

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/alpha_defense/status/1750 ... 98762?s=20 ---> Press Release (Defence):

- Roadmap for India-France Defence Industrial Partnership (Engine).

- Letter of Intent on Defence Space Partnership.

- Roadmap for India-France Defence Industrial Partnership (Engine).

- Letter of Intent on Defence Space Partnership.

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/alpha_defense/status/1750 ... 18590?s=20 ---> EXCLUSIVE: First Look of the 130kN Twin Engine Test Bed Facility.Rakesh wrote: ↑24 Jan 2024 22:19 https://x.com/alpha_defense/status/1746 ... 55924?s=20 ---> GTRE's 130KN TWIN ENGINE TEST BED FACILITY

The work on Civil Works and Allied Services For Engine Test Facility along with Ancillary work for GTRE at Rajankunte Bengaluru has started on 15 September 2023 meanwhile the consultacy work began in July 2023.

The deadline for the completion of all the work is October, 2025. Most of the work load has been alloted to Indian Vendors. This facility will be testing engines with Axi-symmetric nozzles and engines with Thrust Vectored Nozzles (TVN).

Re: Kaveri & Aero-Engine: News & Discussion

Do we have a flying test bed as yet ? wonder if that is some uber sophisticated plane ? ..dont really think it is either, its just a 3 or 4 engine plane with one swapped out and a boatload of instrumentation ?

Re: Kaveri & Aero-Engine: News & Discussion

India could have bought these long time ago

Re: Kaveri & Aero-Engine: News & Discussion

Saar, not able to see images.

Re: Kaveri & Aero-Engine: News & Discussion

I can see images... Change browser? Make BR trusted site?

Re: Kaveri & Aero-Engine: News & Discussion

Do we know for sure that it contains the engine roadmap. I hope we move forward on it quickly! We easily blame other countries for our own lack of movement.Rakesh wrote: ↑27 Jan 2024 00:45 https://x.com/alpha_defense/status/1750 ... 98762?s=20 ---> Press Release (Defence):

- Roadmap for India-France Defence Industrial Partnership (Engine).

Re: Kaveri & Aero-Engine: News & Discussion

We are running around in circles. Kaveri is the path forward. Get serious with it!

Re: Kaveri & Aero-Engine: News & Discussion

All this joint-development roadmap talk etc aside, from a layman pov, it's quite instructive to remember the following 2-3 simple points:Rakesh wrote: ↑26 Jan 2024 20:13 https://x.com/alpha_defense/status/1750 ... 77744?s=20 ---> The French Government has submitted the roadmap for Jet Engine for the combat aircraft to the Indian MoD.

https://x.com/alpha_defense/status/1750 ... 71667?s=20 --->

* Joint IP (Yes)

* Adaptive Cycle (No)

<snip>

1) Sufficient indigenous D&D technological capability exists for developing a 4th Gen Low BPR military turbofan

a) However that doesn't automatically mean existence of same level of mass-manufacturing capability (for 4th Gen TF engine)

e.g. there's whole world of difference between lab-level-producing and mass-manufacturing of, say,

i) SC casted HPT blades and setting up a mass-manufacturing setup of highly automated Investment Casting Furnaces

ii) EBPVD based TBC coatings of 100s of blades

iii) PM Turbine (Ni Superalloy based) and Compressor (Ti based) disks

etc etc

b) The F414 (a 4+ Gen TF) ToAsT deal is aimed at bridging that manufacturing gap, quite a bit - but not fully

c) Even in 4th Gen TF D&D space there are also a few technologies that are yet to be mastered fully.

It doesn't mean these technologies are a must have for a 4th Gen TF D&D, and they are more of "bridging" level between 4th Gen and 5th Gen TF

e.g. Intermetallic (y-TiAl) LPT blades, CMC based Casing/Load-bearing LRUs, Laser Shock Peening & End Wall contouring based HPC Secondary Loss mitigation etc etc

2) From a D&D perspective, what is significantly lacking is comprehensive Testing infrastructure

(though quite a bit of testing infra is already available, in bits and pieces, scattered between GTRE and HAL and few other labs - many of which are now too old and outdated)

3) For future turbofan dev (say for AMCA), we are seeking for a 5th Gen military TF D&D capability - and also the attendant mass-manufacturing capability.

4) Partnering with GE for a F414-EPE+ program would have been quicker, but also riskier (from true D&D level IP sharing etc).

Because, quite a bit of 5th Gen TF tech have already been developed by GE - so that co-dev route etc would have been much quicker, but at teh same time, for them there's no incentive to share any of it, via another co-development route etc. Best that can happen is deeper Mfg ToT, which we are not looking for.

Now wrt the pt 3 above, pls refer to this old post, to get an idea what most probably we are aiming for:

Cross-posting a part of it:

maitya wrote: ↑03 Jul 2023 19:25 ...

For the AMCA turbofan co-development ityadi, what India is aiming for 5th Gen military turbofan tech – India already has almost all aspects of 4th Gen tech, except for funding to demonstrate them in a single platform (like K10, for example).

Below, I have tried to put a list of technologies that most probably, we are trying to achieve, via this joint-dev route (figures in brackets in blue, is what already achieved/exists indigenously via Kaveri program or elsewhere):

Parametric:

1) FAN PR: >=5 (3.4, though 3.7-3.8 achievable)

2) HPC PR: >=6.8-7.0 (6.4)

3) OPR: 30-35 (21.5, though 26.5-27 achievable)

4) BPR: 0.3 - 0.5 (0.16, though 0.2 achievable)

5) TeT: 1600 - 1650deg C (1455deg C, though 1500deg C achievable)

6) Afterburner: 60% of Dry-Thrust with 1.1 Mass-Fraction (45-50%)

Materials:

1) Fan: Ti-Blisks (standard Ti Fan)

2) HPC: Ti MMC based Bling + 1.6-1.8M Blade Tip Speed (Blisk with conventional blade-disk integration via LFW/ECM etc - Transonic Blade tip spee,d 1.1-1.3M)

3) HPC (last/later stages): Ti-Al based or CMC based (Ni Superalloy, PM superalloy for Disc)

4) Combustor: CMC + EBC (Env Barrier Coating), elimination of film cooling (Superalloy + TBC + Film Cooling)

5) HPT Blades: 5th SC Superalloy (DS/SC 3rd/4th Gen Superalloy)

6) HPT Discs: PM Superalloy-Blisk (PM Superalloy std)

7) NGV: CMC (DS Superalloy - maybe even SC Superalloy)

8 ) LPT Blades: CMC (Conventional DS/SC Ni-Superalloy)

9) LPT Discs: CMC (PM of Ni Superalloy)

10) TBC: EBPVD Bilayer LZ-Yt (EBPVD 7/8 Yttria)

11) Coating: Rub Tolerant Coating

12) Shroud/Casings: CMC/MMC (Ni Superalloy)

I'm sure I've missed a lot, but this should be a good starting point, to understand what we are aiming for, technologically, via this joint-dev route.

Re: Kaveri & Aero-Engine: News & Discussion

Rolls-Royce inks agreement with Azad Engineering for making complex defence aero-engine components in India

https://www.indiandefencereview.com/new ... -in-india/

29 Jan 2024

https://www.indiandefencereview.com/new ... -in-india/

29 Jan 2024

Re: Kaveri & Aero-Engine: News & Discussion

maitya ji,

Am I reading your postS right? That Safran/GE know more about GTRE than GTRE themselves?

My impression about RR, WRT GTRE, is that RR is lost.

Am I reading your postS right? That Safran/GE know more about GTRE than GTRE themselves?

My impression about RR, WRT GTRE, is that RR is lost.

Re: Kaveri & Aero-Engine: News & Discussion

Any good news about HAL Engines HTFE-25 and HTSE-1200 gurus? HAL share value is soaring even though unlike its indigenous Engines program.

Re: Kaveri & Aero-Engine: News & Discussion

Rolls Royce is on a signing spree

https://x.com/alpha_defense/status/1752 ... 10539?s=20 ---> Rolls Royce Solutions has signed a MoU with Garden Reach Shipbuilders and Engineers (GRSE) Ltd for locally producing high-quality marine diesel engines. The German company has assented to cooperate with GRSE in the licence production and localisation of the technologically advanced MTU S4000 governmental marine engines.

https://x.com/alpha_defense/status/1752 ... 10539?s=20 ---> Rolls Royce Solutions has signed a MoU with Garden Reach Shipbuilders and Engineers (GRSE) Ltd for locally producing high-quality marine diesel engines. The German company has assented to cooperate with GRSE in the licence production and localisation of the technologically advanced MTU S4000 governmental marine engines.

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/Defencematrix1/status/175 ... 22703?s=20 ---> An update ragarding Kaveri Dry Engine for RPSA (Ghatak): HAL, in collaboration with ADE, will be designing a further indigenized variant of the GTSU-110M2 (The Jet Fuel Starter used in Tejas) to be coupled with the Kaveri Dry Engine for use in the RPSA (Ghatak) Program.

https://x.com/Defencematrix1/status/175 ... 46953?s=20 ---> GTSU-110M2 is the upgraded version of GTSU-110M1. The original GTSU-110 met its design requirements. However, due to a change in requirements requested by IAF, HAL had to bring about major upgrades. GTSU-110M2 is in service with the serially produced Tejas aircraft.

https://x.com/Defencematrix1/status/175 ... 40143?s=20 ---> GTSU-110M2 is capable of 3 consecutive starts with a 75 second time interval. The original GTSU-110 (not M1) required a time interval of 10 minutes for the second start and 30 minutes for the third. Further, the starting altitude was improved from 3.2 km to 6 km.

https://x.com/Defencematrix1/status/175 ... 46953?s=20 ---> GTSU-110M2 is the upgraded version of GTSU-110M1. The original GTSU-110 met its design requirements. However, due to a change in requirements requested by IAF, HAL had to bring about major upgrades. GTSU-110M2 is in service with the serially produced Tejas aircraft.

https://x.com/Defencematrix1/status/175 ... 40143?s=20 ---> GTSU-110M2 is capable of 3 consecutive starts with a 75 second time interval. The original GTSU-110 (not M1) required a time interval of 10 minutes for the second start and 30 minutes for the third. Further, the starting altitude was improved from 3.2 km to 6 km.

Re: Kaveri & Aero-Engine: News & Discussion

@ maitya-ji: some ToAsT information for you

Safran Offers 100% Technology Transfer in India’s Shakti Jet Engine Project

https://bharatshakti.in/safran-offers-1 ... e-project/

27 Jan 2024

Safran Offers 100% Technology Transfer in India’s Shakti Jet Engine Project

https://bharatshakti.in/safran-offers-1 ... e-project/

27 Jan 2024

Re: Kaveri & Aero-Engine: News & Discussion

NRao ji, I wouldn't go that far ... however having repeatedly being involved in consultancy, audit, critical component exports etc, they (specifically Safran) would have very good idea about strengths/weakness/technological depth/pitfalls/achievements of most of GTRE's flagship programs (like Kaveri).

Snecma, of course, came very close to active participation in the program, once around 2012 (and the other around 2017-18 IIRC) but things didn't work out both the times, supposedly over the high-price that they'd demanded then.

Similarly, not only with GTRE, but also with HAL Engine Div, GE have had quite a bit of interaction/consultancy/bids etc for a while now - infact, and again IIRC, the precursor to the the current F414-INS6 ToAsT negotiations, there was a similar to-and-fro on F414 mfg related ToT (albeit with much lower ToT %, approx 50% etc) back in 2011-12.

Wrt RR, the collaboration is actually quite old - for Adour Mk 811, we do make the HPT blades, discs and vanes (and compressor blades and discs and various other critical components) in HAL facilities, for more than decade+ now. Too bad RR missed the bus, IMVHO, wrt taking that partnership forward. They got a golden opportunity wrt Jaguar re-engine initiative, which eventually got shelved (due to very high price demanded by Honeywell, IIRC, for F125IN), is now playing catching-up.

In fact, Kaveri is one program, where-in GTRE had never really shied away from approaching (and getting Audited etc as well) such foreign OEMs all the time - be it RR, GE, Snecma, Ger, even Russia etc etc - there's an decade+ old post of mine, on this aspect of foreign collaboration etc, maybe now in the Gyan thread, you may want to dig it up and refer it.

Wrt RR lost etc - I think you're referring to the AMCA 110-120-130-whatever KN TF program.

Well, it seems it's now quite settled that it'll be Snecma all the way - maybe, and none of us would know, the haggling is wrt how much of the reported asking price, which, knowing the French, would be ultra steep, can be offset via the future Rafale purchase offsets etc.

But in India Defense Procurement world, nothing is certain unless the deal is actually signed, so let's see.

-----------------------

*Note - Whatever happened to the so-called GE funding (partially) the high-altitude test facility setting up etc, part of 404 engine deal many years back. Ditto wrt the same aspects, wrt the 36 Rafale purchase offsets.

All reports seems to suggest that facility setting up etc is being purely funded by us, but not very sure though.

Re: Kaveri & Aero-Engine: News & Discussion

The IAF chief is reportedly confident that Indian can develop an indigenous GE F414 alternative.

Re: Kaveri & Aero-Engine: News & Discussion

IDRW...so FWIW

@ Maitya-ji: Take a bow

IAF Chief confident that India can develop alternatives to the F414-GE-INS6 engine locally

https://idrw.org/iaf-chief-confident-th ... e_vignette

31 January 2024

Re: Kaveri & Aero-Engine: News & Discussion

The Services always have confidence on products that will come after years. The real question is about the the products that are ready or almost ready.

-

Prem Kumar

- BRF Oldie

- Posts: 4434

- Joined: 31 Mar 2009 00:10

Re: Kaveri & Aero-Engine: News & Discussion

What is this news I am hearing about the new/upgraded Kaveri generating 81 kN in thrust with afterburners, which will rival the GE 404s?

Is this a plan/goal or do we already have a test variant that can generate the above thrust?

Is this a plan/goal or do we already have a test variant that can generate the above thrust?

Re: Kaveri & Aero-Engine: News & Discussion

Rakesh-ji, yes from IDRW, so needs to be taken with more than a bucket of salt ... but, surprisingly, even the Indian Defense Updates video report has the same/similar details.Rakesh wrote: ↑31 Jan 2024 18:07IDRW...so FWIW

@ Maitya-ji: Take a bow

IAF Chief confident that India can develop alternatives to the F414-GE-INS6 engine locally

https://idrw.org/iaf-chief-confident-th ... e_vignette

31 January 2024

Frankly hearing this Kaveri Mk2, for the first time ...

And that too when there's considerable confusion, atleast in my mind, wrt what's cooking wrt the 81KN baseline Kaveri variant.

I mean, is this the old K9 + new A/B

or

Kaveri-dry-variant + new A/B

or

updated/improved Kaveri-dry-variant + new A/B.

Which one?

Either way whilst all this talk is fine, and is in fact encouraging as well, but where's the funding and where's a public announcement of these program-sanctions.

Betw, irrespective of which one it is, it'll be a tough/difficult to graduate it, to a F414-INS6 equiv (supposedly the so-called Kaveri Mk2).

Remember the path taken by GE for the F404 to F414 was diametrically opposite to what most established TF OEM would have done i.e. look for thrust-enhancement via improvement of the Mass Flow of course but via the LPT-Fan/LPC regimes while maybe tweaking the HPT-HPC a bit etc (e.g. M88-2 to M88-3 or EJ200 Stage-2 etc) - you can read about it here.

GE actually reduced the BPR (from F404) and also tweaked the inlet geometry a bit as well - the whole focus was to increase the mass-flow-thru-core massively/disproportionately and then go for thrust increment via higher TeT levels achieved thru next-gen technologies in the HPT (4th Gen SC etc), the HPC stages (BLISK design etc) and next-gen Combustor.

But, with the Kaveri design, since we have constrained ourselves with an ultra-low BPR values (due to the flat-rating etc requirement), so dry-thrust improvements via the mass-flow improvement of the LPT-Fan/LPC route, wouldn't be significant enough.

Some amount of-course is possible and I'm sure that'd be tried as well, but that's not in the critical path for higher thrust achievement.

Instead, and if you have closely followed (and I'm sure you must have) whatever little was happening in the dry-Kaveri etc follow-on programs, the whole focus was towards improving the Fan/LPC flow path/efficiency.

Needless to say, aiming for higher efficiency and higher SPR of the HPC stages (and more HPC rpm as well) is quite highly dependent on it's inlet mass-flow pattern - there are of course are other major factors as well.

So, like GE F414 program, our aim of increasing the dry-thrust levels, by say 20-22%, looks to be via the increasing TeT route i.e achieving 1550-1575deg C TeT levels (so, 100-125deg C increment), with matching-up increment in OPR levels (of say 28-29 levels).

Which in turn means,

1) In the Turbine complex - 4th Gen SC based HPT, better HPT blade-cooling architecture, better TBC, maybe 4th Gen DS Vanes (SC ones would be prohibitively costly), PM turbine discs etc

2) Next Gen Combustor (read improved cooling design)

3) HPC Complex - Ti BLISK (or BLINGs, if possible) for the HPC stages (atleast the first 3-4 stages), Secondary loss reduction technologies, maybe even Y-TiAl based last HPC stage (instead of the heavier Ni-Superallpy ones) etc.

4) Spool weight reduction (maybe via CMC route), extensive usage of PMC and CMC in Casings and Shrouds

etc etc

These technological aspects are actually pushing 5th Gen TF technology levels in quite a big way - won't be easy that’s for sure, and certainly won't be cheap.

But what is very sure is that this F414 ToAsT deal will not have any +ve impact/influence on it.

I mean, if you try and read between the lines what's the so-called 20% manufacturing technologies that will be withheld, compare to what I've written above, it shouldn't be too difficult to understand this.

Let's see ...

Re: Kaveri & Aero-Engine: News & Discussion

maitya ji,maitya wrote: ↑30 Jan 2024 21:54NRao ji, I wouldn't go that far ... however having repeatedly being involved in consultancy, audit, critical component exports etc, they (specifically Safran) would have very good idea about strengths/weakness/technological depth/pitfalls/achievements of most of GTRE's flagship programs (like Kaveri).

Snecma, of course, came very close to active participation in the program, once around 2012 (and the other around 2017-18 IIRC) but things didn't work out both the times, supposedly over the high-price that they'd demanded then.

.................................

Thanks!!

Thinking aloud.

If they have a "very good idea about strengths/weakness/technological depth/pitfalls/achievements of most of GTRE's flagship programs" AND excel spreadsheet (from their own research) worth of data, then they surely are in a better position than GTRE to predict the future of Kaveri++. Simply because GTRE does not have enough data to extrpolate, while they have enough data to extrapolate. From a risk PoV, GTRE has very high risks, they have much lower (because they have data)(granted the data they have is "risky", but, that is better than having no data at all).

Re: Kaveri & Aero-Engine: News & Discussion

https://twitter.com/Varun55484761/statu ... 7609418851

GTRE is using Danobat High Speed Blade Tip Grinder. These machines grind, deburr, and measure the blade tips of assembled turbine engines and APU rotors while they are being spun at speeds up to 7000 rpm.

See video:- https://youtu.be/nWniDEQjEOk

Re: Kaveri & Aero-Engine: News & Discussion

For the record:

https://twitter.com/Varun55484761/statu ... 3835257859

https://twitter.com/Varun55484761/statu ... 3835257859

GTRE using Italian Firm Parpas CNC Blisk machining tools for Bladed Disk( Blisk).

In pic an old image of GTRE BLISK Rotor at testing facility.

https://pbs.twimg.com/media/GFd-m4iagAA ... name=small

Re: Kaveri & Aero-Engine: News & Discussion

From frontier India:

France Really Giving India “All” Its Jet Engine Tech? Sounds Too Good to be True?

France Really Giving India “All” Its Jet Engine Tech? Sounds Too Good to be True?

The story is scarcely believable. Jawed Ashraf, the Indian ambassador to France, offered insight in January into ongoing talks regarding an aircraft engine contract between India and Safran, the second-largest aerospace equipment manufacturer in the world. Safran is an aerospace and defence equipment manufacturer that designs, develops, and produces aircraft and rocket engines, among other products. The aim is to synchronise the engine specifications with India’s forthcoming combat aircraft requirements. In addition to technology transfer, the agreement intends to address design, metallurgy, and other crucial aspects. In India, we call it a 100% transfer of technology and Intellectual Property Rights.

According to the diplomat, negotiations between Safran and Hindustan Aeronautics Ltd aim to align the engine specifications with India’s future needs for combat aircraft. Ambassador Ashraf stated that India sought a comprehensive approach to technology transfer beyond mere manufacturing technology transfer. The agreement aims to deepen the design phase, metallurgical aspects, and other critical elements contributing to developing advanced jet engines.

The diplomat asserts that the negotiations between Safran and Hindustan Aeronautics Ltd. aim to harmonise the engine specifications with India’s forthcoming combat aircraft requirements. As stated by Ambassador Ashraf, India aimed to adopt a holistic approach to technology transfer that extended beyond the simple transfer of manufacturing technology. The agreement aims to enhance the design phase, metallurgical considerations, and other pivotal components contributing to advancing aircraft engine technology.

The ambassador underscored the ongoing nature of these discussions as part of the defence industry’s strategic plan. India and France decided in July 2023 to enhance their defence collaboration in advanced aerospace technologies through a collaborative effort to develop a combat aircraft engine. Additionally, they agreed to endorse industrial collaboration with Safran Helicopter Engine to power large helicopters as part of the Indian Multi-Role Helicopter (IMRH) programme.

The announcement was made after discussions between Prime Minister Narendra Modi and French President Emmanuel Macron in Paris. Ross McInnes, president of Safran, met with Prime Minister Modi in April 2023 to discuss a technological partnership in the space and defence industries. Safran Helicopter Engines and Hindustan Aeronautics (HAL) also entered a task-sharing agreement to collaborate on the engine development for the forthcoming Indian multi-role helicopter (IMRH).

The French generosity surpasses that of the United States, which has reached an agreement to transmit the F414 jet engine manufacturing technology to India. Already supplying F404 engines manufactured in the United States for India’s Tejas aircraft, GE was awarded the contract in 2010 to supply the F414, a more potent variant designed for a new generation of aircraft.

The gas turbine aircraft engine is one of the highest technological creations of the human mind, and only a few countries in the world, only five, have such technology. It’s not likely that any country will give this technology to another government.

While France promised to provide major help and knowledge transfer for initiatives such as the Kaveri engine, it has consistently fallen short of achieving complete transfer. Unless reliable confirmation from the French government and clarity on the exact technology being transferred, claims of total jet engine technology transfer should be viewed cautiously. Partial support, consultation, or co-development might appear more credible. However, France’s decision to hand up its entire engine intellectual property to India appears exceedingly doubtful.

If you recall, the Comptroller and Auditor General of India issued harsh warnings in 2020 about foreign companies such as Dassault Aviation failing to meet domestic investment obligations when receiving procurement contracts. The Ministry of Defence (MoD) has removed the offset provision from inter-government and single-vendor procurement of defence platforms.

So, either Ambassador Jawed’s insights aren’t understood, or they were misquoted. Or was it a trial balloon to sell the justification of Marcon attending the Republic Day Parade after US President Joe Biden said he wouldn’t? After all, announcing loudly and withdrawing silently is a trick in politics and diplomacy.

There are several reasons why designing and constructing gas turbine engines for aircraft is difficult:

Extreme working conditions: To generate sufficient thrust, aircraft engines must run at extremely high temperatures, pressures, and rotational speeds. This places significant demands on the materials and moving elements. Engine components must resist these extreme conditions for extended periods.

Efficiency: Aircraft engines must be exceedingly efficient in order to reduce fuel consumption. Even little efficiency gains necessitate extensive optimisations of engine thermodynamics and aerodynamics.

Reliability: Because aircraft engines run at such high power levels, they must be exceedingly dependable. Even slight blunders might have disastrous repercussions. This necessitates strict tolerances, redundant systems, and rigorous testing.

Weight: is always a factor in aircraft design. The engine must be as lightweight as feasible while still producing sufficient power. Achieving the ideal balance is tricky.

Noise: Aircraft engines must meet stringent noise requirements. It is difficult to reduce noise through engine design improvements while maintaining performance.

Emissions: Controlling the emission of gases such as nitrogen oxides necessitates complex combustion chamber designs and exhaust treatment systems.

Integration: The engines must be physically integrated into the aircraft architecture and systems.

To summarise, aircraft gas turbine engines push many parts of mechanical engineering to their limits, necessitating innovative solutions and advanced designs to fulfil the high demands of aviation. Even little changes necessitate significant work and invention.

Learning from Past Mistakes: Can India Finally Achieve Jet Engine Self-Sufficiency?

Since the 1980s, India has attempted to create a gas turbine engine dubbed Kaveru for the Indian Light Combat Aircraft Project. Several main factors contributed to the difficulty and delays in India’s Kaveri jet engine project:

Technological complexity: Developing cutting-edge jet engine technology demands decades of knowledge. India attempted to condense that time span, which resulted in technical challenges.

Lack of infrastructure and ecosystem: At the time, India lacked the specialised infrastructure, industrial ecosystem, and supply chains required to develop advanced jet engine technologies.

Integration issues: The Kaveri engine had difficulty properly integrating and operating with the intended LCA Tejas fighter aircraft, necessitating numerous design changes.

Materials technology: India failed to create the specific materials required to endure jet engine stresses and temperatures. Things like single crystal turbine blades were a challenge.

Funding instabilities: Over several decades, the project received intermittent funding. Budget cuts and changes make it impossible to ensure consistency.

Changing needs: Over time, specifications for the Kaveri engine’s thrust output and performance have altered, necessitating revision.

Sanctions: Following India’s nuclear weapons tests in 1998, sanctions were imposed, preventing other countries from gaining access to advanced engine technology.

Lack of experience: Indian engineers had no experience designing sophisticated turbofan engines. Knowledge had to be developed from the start.

After Decades of Delays, India Restarts Kaveri Engine Project

While the Kaveri did not meet its objectives, the knowledge gathered would benefit future Indian jet engine efforts with likely partners – Safran or Rolls Royce. However, overcoming all of these hurdles proved extremely challenging.

India recently restarted the Kaveri project. Initiatives are underway to restore and continue the development of India’s Kaveri jet engine project.

The Indian government invested over $140 million in 2017 to relaunch the Kaveri engine programme. Since then, additional funds have been provided. Developing the Kaveri, the Gas Turbine Research Establishment (GTRE) has overcome technical concerns and enhanced the engine’s performance. In 2018, French corporation Safran signed an agreement to provide technical help to the Kaveri programme, notably in high-tech sectors that previously presented issues for India. The Kaveri engine will be developed to power the Tejas Mk1A and Mk2 fighter planes. It is planned to generate 95 to 100 kilonewtons of dry thrust.

In addition to the Tejas, the Kaveri is the basic engine for more advanced future aircraft, such as stealth fighters and medium transports.

The knowledge acquired with the core Kaveri engine is being applied to the new Kaveri derivative engines in development, such as the Dry Engine for the Ghatak UCAV, now called Remotely Piloted Strike Aircraft (RPSA).

While delays are still anticipated, there is renewed hope that an operating Kaveri engine will be available over the next 5-7 years with this programme relaunch and outside technical support.

So, while prior challenges remain, the Kaveri engine programme appears to be making significant progress towards an indigenous Indian jet engine through consistent efforts.

Re: Kaveri & Aero-Engine: News & Discussion

Any rough estimate on the cost difference between DS & SC for a given component?

Re: Kaveri & Aero-Engine: News & Discussion

Haridasji, actually there's no root issue really, certainly not wrt SCB etc - especially, since SCB was not required as the DS casted HPT blades used were a gen ahead than the 3rd Gen SC ones.Haridas wrote: ↑05 Jan 2024 13:12So SCB is a red herring, the root issue is elsewhere.chetak wrote: ↑15 Jun 2023 12:10 a few organizations in India are already doing this

but one would hesitate to say if the technology has been mastered in a general way and therefore, is capable of being adapted to various engines under development or they are doing it from ready made kits which have all the materials required and is being used merely as a technology demonstrator to develop the skill sets required.

Some speculate it's hot section, but good engineer can with public available daya peer through the GTRE kimono. Could be area other than hot section !

<snip>

Yes, Material Sc/Metallurgical aspects were really really challenging (as it is the case with any TF program globally), but for the Kaveri program, those are not really linked to SC HPT blades casting etc - in fact there are no issues with the Gas Generator itself, it does much better than most other contemporaries actually.

Having said that, and as it is already very well known now, K9 attained the specified dry thrust levels (and other parameters like SFC etc), went very close to the wet thrust levels, but was overweight by 150Kg - yes the A/B and the overall weight was the disappointment/failure, but for an ab-initio initiative for, what is arguably the most technically complex endeavor there-is, this should be quite normal/expected actually.

And, as the intended platform grew on weight (designed from 5.5Ton empty, ended up with 6.2-6.3ton), and thus the thrust requirements went up - so it became all too easy for the MoD baboons (and the user community) to simply kill the program by starving it of whatever little pittance (so-called funding) they were spending on the program. The "lost decade" of 2010/11 - 2021/22, was just the killer blow that was needed to keep us dependent on imports, for almost all of our strategic programs (Mk2, TEDBF, AMCA etc), for next foreseable future.

Any other country, serious about developing an indigenous capability, on something as techincally complex as a low bypass military TF, would have simply funded it's development and certification atleast. But not us ...

Oh well ...

Anyway, now that we are hearing some encouraging noises, every now then, the latest being this so-called Kaveri Mk2 (trying to achieve F414 equiv performance)- this has rekindled my interest to dust-off and revamp my 1.5decade+ old TurboFan Sim, which was, in those days, very heavily inspired by the Rocksim by one Arun_Sji.

This attempt has more to do with trying to model this so-called Kaveri Mk2, that is being speculated by everybody - and try and map-out the evolution path that'll be required to be pursued and thus bring out some "objectivity" to the points that I've made above (prev post).

The key to understanding the model is to go from one version to another, left to right (Base/Current -> Ver 1 -> Ver 2(a) -> Ver 2(b) -> Ver3), comparing the incremental change of various derived perf parameters, as the input conditions are gradually changed. These changes in input conditions are themselves all about graduating one tech gen to next. I'll be covering these changes, and the reasoning behind those changes, in the 3-part anal-sys posts, after this one.

===================================================================

But first the disclaimers: The derived absolute values and parameters, should NOT be considered to be what can be or has been achieved etc. As, a large amount of dumbing down and atrociously generalized parameter values (plus generic text-book level formulae) have been assumed on almost every aspect of the derivation, to keep this as layman-ish as possible and thus something that can be used for generic forum discussions like here.

However, a generalized tool like this helps in understanding or illustrating various aspects of Turbofan design and the performance impact of tinkering in certain areas, which most of the times may not be that obvious.

The Basic Parameters used here are from what has been published time to time, over last 2+ decades, and is open source.

But before I go ahead with my anal-sys, a very humble request to my fellow BRFites:

Pls try and refrain from posting on this thread for next 2-3 days, allowing me to complete the 3 part series, one after another. This will help folks reference the models, as they go thru the relevant anal-sys (as the model illustration will require frequent referencing to fully grasp the analysis).

Re: Kaveri & Aero-Engine: News & Discussion

[Hypothetical Kaveri Mk2 - Modelling Analysis - Part 1]

Now, the Ver 1 column, assumes that we take the baseline K9, and only touch the LPT and the Fan/LPC, to improve the Fan/LPC PR levels moderately.

Doing so, (pls refer to Rows 4-6) will improve the OPR obviously (from the Fan/LPC component - but also, since the HPC inlet flow will also be further streamlined, there's bound to be some (not much) improvement to HPC PR (and efficiency levels), thereby exhibiting quite a dramatic OPR improvements.

However, pls notice (pls refer to Rows 38-40) how the overall dry thrust level didn't change much (actually has remained constant), but the overall efficiency has improved a bit. However, this improvement is mostly via improvement of the Propulsive Efficiency, and not Thermal efficiency.

(Propulsive efficiency, though good, is not that much of an important factor in a military TF, compared to say Thermal efficiency improvements).

But the real issue is (pls refer to Rows 29-30), though the dry-thrust component from the Fan/LPC has gone up somewhat, but the dry-thrust component from the Core has actually gone down, almost balancing out each other.

This is because, (pls refer to Rows 21-26) whilst the Work extracted by the LPT went up a notch and the Work obtained from Core remained same (so there's a small increment in overall work extraction), but the work/power required to drive the Fan/LPC complex, and even the compressors, went up - leaving a reduced level of work/power available to accelerate the mass-flow thru core, thus impacting it's dry-thrust component.

Another way of looking at it is, (pls refer to Row 27-28), the Fan exit velocity has gone up, which means the Fan/LPC is able to accelerate, whatever little mass-flow that's being bypassed, a little more, thus increasing the dry thrust component from the Fan.

So that means, for a low BPR TF designs (like Kaveri), trying to increase the thrust levels via the low-risk route of, LPT-Fan/LPC improvements, while leaving the Core alone, wouldn't yield any substantial gains.

Sure there'll be some level of efficiency gain though, but that's about it.

Now the fun part, and some may want to consider it as an assignment - pls try out the same calc/derivations, with a higher BPR level TF design like the F404 (or even M88-2 or EJ-200) and see what happens.

Now, the Ver 1 column, assumes that we take the baseline K9, and only touch the LPT and the Fan/LPC, to improve the Fan/LPC PR levels moderately.

Doing so, (pls refer to Rows 4-6) will improve the OPR obviously (from the Fan/LPC component - but also, since the HPC inlet flow will also be further streamlined, there's bound to be some (not much) improvement to HPC PR (and efficiency levels), thereby exhibiting quite a dramatic OPR improvements.

However, pls notice (pls refer to Rows 38-40) how the overall dry thrust level didn't change much (actually has remained constant), but the overall efficiency has improved a bit. However, this improvement is mostly via improvement of the Propulsive Efficiency, and not Thermal efficiency.

(Propulsive efficiency, though good, is not that much of an important factor in a military TF, compared to say Thermal efficiency improvements).

But the real issue is (pls refer to Rows 29-30), though the dry-thrust component from the Fan/LPC has gone up somewhat, but the dry-thrust component from the Core has actually gone down, almost balancing out each other.

This is because, (pls refer to Rows 21-26) whilst the Work extracted by the LPT went up a notch and the Work obtained from Core remained same (so there's a small increment in overall work extraction), but the work/power required to drive the Fan/LPC complex, and even the compressors, went up - leaving a reduced level of work/power available to accelerate the mass-flow thru core, thus impacting it's dry-thrust component.

Another way of looking at it is, (pls refer to Row 27-28), the Fan exit velocity has gone up, which means the Fan/LPC is able to accelerate, whatever little mass-flow that's being bypassed, a little more, thus increasing the dry thrust component from the Fan.

So that means, for a low BPR TF designs (like Kaveri), trying to increase the thrust levels via the low-risk route of, LPT-Fan/LPC improvements, while leaving the Core alone, wouldn't yield any substantial gains.

Sure there'll be some level of efficiency gain though, but that's about it.

Now the fun part, and some may want to consider it as an assignment - pls try out the same calc/derivations, with a higher BPR level TF design like the F404 (or even M88-2 or EJ-200) and see what happens.

Re: Kaveri & Aero-Engine: News & Discussion

[Hypothetical Kaveri Mk2 - Modelling Analysis - Part 2]

Now for the Ver 2, and there are 2 of them (2a and 2b), with both assuming, GTRE/DMRL/MIDHANI et all have the achieved the required capability and technical maturity to implement an HPT turbomachinery capable of handling 1545-1550deg C level of TeT, a good 100deg C more that what current K9 version etc achieves.

Do note here, such a high TeT increment, is globally considered "minm a generation-straddling" capability in terms of Turbomachinery, Rotor Dynamics & CFD, Material Sc etc etc.

Such high TeT levels will require 1100deg C level of metal-temp capability of HPT blades and vanes - which means,

1) minm 4th Gen SC (for blades) and 4th Gen DS (for blades) and the associated mass manufacturing level of Tech for ceramic molds etc (Alumina based molds, Silica based ones won't work), very-high automation levels in Vacuum Investment Casting machinery etc etc etc

2) highly evolved blade internal-cooling architecture (diff architecture for blades and vanes betw)

3) Adv Film cooling (read laser drilling)

3) TBC (minm 8YZ levels)

4) PM Discs

etc etc.

(have written tomes on this aspect over many years now, so won't belabor on it anymore)

But since DMS4 based HPT blades (and DMD4 based HPT Vanes) has been already demonstrated, maybe it ok to assume that GTRE et all have developed the wherewithal of such a TeT capability.

Such TeT values are bang in the M-88-2/EJ200/F414 territory, actually maybe even slightly better of some of them.

Now the Ver 2(a), assumes, GTRE et all implements this TeT, in the baseline K9 version, without any other changes to other turbomachinery components like LPT, HPC, Fan/LPC etc.

Do note here that though such an arrangement is theoretically possible, but practically such an TeT increment is bound to impact the HPC RPM and it's PR.

As you'll notice (pls refer to Row 29-31), the Dry thrust increases quite a bit, by approx 7.5% etc, but all of it is from the Core i.e. more and more trending towards the turbojet territory.

As a result (pls refer to Row 32-35), though the Thermal efficiency goes up, the propulsive efficiency reduces, and the overall efficiency stagnates (actually slightly falls). The SFC also improves.

So a better heat-engine, yes, but not a very efficient propulsive system.

There are other limitations as well:

i) (pls refer to Row 27), the Engine exit velocity has gone up, which is not a such a good thing as the stagnation pressure of the turbine exit would reduce, which in turn will impact the A/B combustor efficiency (requiring more "brute force" of more fuel mixing, to pump out a higher wet thrust)

ii) (pls refer to Row 19-20) Both the HP turbine exit temp and LP turbine exit temps have gone up, meaning demand for more focus on the thermal mgmt aspects of the LP turbine etc.

But overall, a good intermediate step, for a modest perf improved version - something that other 4th Gen TF design would have tried to achieve via the less risky (Ver 1) LPT-Fan/LPC route. A price to pay, wrt achieving the flat-rating requirement.

But still not even close to the F414 equiv thrust levels.

Now for the Ver 2, and there are 2 of them (2a and 2b), with both assuming, GTRE/DMRL/MIDHANI et all have the achieved the required capability and technical maturity to implement an HPT turbomachinery capable of handling 1545-1550deg C level of TeT, a good 100deg C more that what current K9 version etc achieves.

Do note here, such a high TeT increment, is globally considered "minm a generation-straddling" capability in terms of Turbomachinery, Rotor Dynamics & CFD, Material Sc etc etc.

Such high TeT levels will require 1100deg C level of metal-temp capability of HPT blades and vanes - which means,

1) minm 4th Gen SC (for blades) and 4th Gen DS (for blades) and the associated mass manufacturing level of Tech for ceramic molds etc (Alumina based molds, Silica based ones won't work), very-high automation levels in Vacuum Investment Casting machinery etc etc etc

2) highly evolved blade internal-cooling architecture (diff architecture for blades and vanes betw)

3) Adv Film cooling (read laser drilling)

3) TBC (minm 8YZ levels)

4) PM Discs

etc etc.

(have written tomes on this aspect over many years now, so won't belabor on it anymore)

But since DMS4 based HPT blades (and DMD4 based HPT Vanes) has been already demonstrated, maybe it ok to assume that GTRE et all have developed the wherewithal of such a TeT capability.

Such TeT values are bang in the M-88-2/EJ200/F414 territory, actually maybe even slightly better of some of them.

Now the Ver 2(a), assumes, GTRE et all implements this TeT, in the baseline K9 version, without any other changes to other turbomachinery components like LPT, HPC, Fan/LPC etc.

Do note here that though such an arrangement is theoretically possible, but practically such an TeT increment is bound to impact the HPC RPM and it's PR.

As you'll notice (pls refer to Row 29-31), the Dry thrust increases quite a bit, by approx 7.5% etc, but all of it is from the Core i.e. more and more trending towards the turbojet territory.

As a result (pls refer to Row 32-35), though the Thermal efficiency goes up, the propulsive efficiency reduces, and the overall efficiency stagnates (actually slightly falls). The SFC also improves.

So a better heat-engine, yes, but not a very efficient propulsive system.

There are other limitations as well:

i) (pls refer to Row 27), the Engine exit velocity has gone up, which is not a such a good thing as the stagnation pressure of the turbine exit would reduce, which in turn will impact the A/B combustor efficiency (requiring more "brute force" of more fuel mixing, to pump out a higher wet thrust)

ii) (pls refer to Row 19-20) Both the HP turbine exit temp and LP turbine exit temps have gone up, meaning demand for more focus on the thermal mgmt aspects of the LP turbine etc.

But overall, a good intermediate step, for a modest perf improved version - something that other 4th Gen TF design would have tried to achieve via the less risky (Ver 1) LPT-Fan/LPC route. A price to pay, wrt achieving the flat-rating requirement.

But still not even close to the F414 equiv thrust levels.

Re: Kaveri & Aero-Engine: News & Discussion

[Hypothetical Kaveri Mk2 - Modelling Analysis - Part 3]

Now enter Ver 2(b).

As I've said a gazillion times now, and is in fact a pretty well-known thumb rule wrt TF design, it's never a good idea to unilaterally increment either the TeT or the OPR.

Doing so, the actual work extracted by the turbines will actually fall, if either of this route is pursued - it will fall less dramatically for an ultra-low BPR design like Kaveri (e.g. Ver 1(a) above) than a higher BPR design, but fall it will.

Pls refer to this graph, towards the bottom of one of my prev posts (and in many of my very old posts in gyan and other threads).

So Ver 2(b), looks at improving both the HPC and LPC PRs and the efficiencies, keeping the higher TeT aspects, same as in Ver 2(a) - (pls refer to Rows 04- 06).

And these PR and efficiency improvements are actually inevitable, as:

Increasing TeT will increase the HPT (and LPT as well) turbines -> increasing the corresponding shaft RPMs -> will increment the HPC (and Fan/LPC) rpms -> and thus increasing the SPR of their individual stages -> ultimately raising their overall PRs.

But a word of caution:

i) Willy-nilly increasing the HPC RPMs may result in catastrophic HPC surge and choking situations - something the designers would have to carefully calibrate and control.

ii) Increasing RPM of the HPC stages would result in temp increase across the HPC stages - so Ti based 1-5 stages may not work out, may have to go for the heavier Ni Superalloy route for the 5th stage as well (6th stage is already Ni Superalloy).

iii) Increasing RPM of the HPC stages, will invariably increase the secondary loss profiles and the mitigating techs (e.g end wall contouring, rim-casing rubbing etc) may require a fresh relook.

These aspects needs to be very carefully considered, and additional mitigating technologies deployed, before any such design changes are made.

Anyway, back to topic - incrementing both the TeT and OPR levels would result in further Dry thrust and efficiency increments (pls refer to Row 31 - 37), but still would fall way short of F414 levels.

Pls note the overall Dry Thrust levels may not have gone up by that much (compared to Ver 2(a)), but the improvements to SFC and efficiency figures, indicates a well-designed all-round TF performance.

Both the turbines (HPT and LPT) are extracting way more work (pls refer to Row 21 - 24), allowing more energy/power for the HPC and Fan/LPC (to rotate faster).

Also, the Turbine exit temps (pls refer to Row 19 - 20), have been brought down quite a bit, back to manageable levels -> allowing the A/B to breathe easy/normally.

Also do note, the OPR and TeT levels assumed here-in, is by and large what the most cutting-edge 4th Gen TFs (read M88-2, EJ-200, even F404-IN20 etc) achieve.

The programs for natural successor to these TFs like M88-3, EJ-200 stage 2 and 3 etc, have long been abandoned, mostly due to lack of funds, that would have been required to develop quite a few of the 5th Gen level techs, required to achieve the target performance parameters.

So the corollary can be, barring deployment of large-scale 5th Gen tech, the Kaveri in its current form factor, this is probably the ultimate/max thrust levels that it can achieve.

But but, all these may be well and good, the thrust levels achieved are still not in the F414 league.

Now enter Ver 2(b).

As I've said a gazillion times now, and is in fact a pretty well-known thumb rule wrt TF design, it's never a good idea to unilaterally increment either the TeT or the OPR.

Doing so, the actual work extracted by the turbines will actually fall, if either of this route is pursued - it will fall less dramatically for an ultra-low BPR design like Kaveri (e.g. Ver 1(a) above) than a higher BPR design, but fall it will.

Pls refer to this graph, towards the bottom of one of my prev posts (and in many of my very old posts in gyan and other threads).

So Ver 2(b), looks at improving both the HPC and LPC PRs and the efficiencies, keeping the higher TeT aspects, same as in Ver 2(a) - (pls refer to Rows 04- 06).

And these PR and efficiency improvements are actually inevitable, as:

Increasing TeT will increase the HPT (and LPT as well) turbines -> increasing the corresponding shaft RPMs -> will increment the HPC (and Fan/LPC) rpms -> and thus increasing the SPR of their individual stages -> ultimately raising their overall PRs.

But a word of caution:

i) Willy-nilly increasing the HPC RPMs may result in catastrophic HPC surge and choking situations - something the designers would have to carefully calibrate and control.

ii) Increasing RPM of the HPC stages would result in temp increase across the HPC stages - so Ti based 1-5 stages may not work out, may have to go for the heavier Ni Superalloy route for the 5th stage as well (6th stage is already Ni Superalloy).

iii) Increasing RPM of the HPC stages, will invariably increase the secondary loss profiles and the mitigating techs (e.g end wall contouring, rim-casing rubbing etc) may require a fresh relook.

These aspects needs to be very carefully considered, and additional mitigating technologies deployed, before any such design changes are made.

Anyway, back to topic - incrementing both the TeT and OPR levels would result in further Dry thrust and efficiency increments (pls refer to Row 31 - 37), but still would fall way short of F414 levels.

Pls note the overall Dry Thrust levels may not have gone up by that much (compared to Ver 2(a)), but the improvements to SFC and efficiency figures, indicates a well-designed all-round TF performance.

Both the turbines (HPT and LPT) are extracting way more work (pls refer to Row 21 - 24), allowing more energy/power for the HPC and Fan/LPC (to rotate faster).

Also, the Turbine exit temps (pls refer to Row 19 - 20), have been brought down quite a bit, back to manageable levels -> allowing the A/B to breathe easy/normally.

Also do note, the OPR and TeT levels assumed here-in, is by and large what the most cutting-edge 4th Gen TFs (read M88-2, EJ-200, even F404-IN20 etc) achieve.

The programs for natural successor to these TFs like M88-3, EJ-200 stage 2 and 3 etc, have long been abandoned, mostly due to lack of funds, that would have been required to develop quite a few of the 5th Gen level techs, required to achieve the target performance parameters.

So the corollary can be, barring deployment of large-scale 5th Gen tech, the Kaveri in its current form factor, this is probably the ultimate/max thrust levels that it can achieve.

But but, all these may be well and good, the thrust levels achieved are still not in the F414 league.

Re: Kaveri & Aero-Engine: News & Discussion

[Hypothetical Kaveri Mk2 - Modelling Analysis - Part 4]

Enter the Ver 3 ...

But before we get to it, let's briefly analyse at very very high level, what GE did to evolve the F404 TF to F414 levels.

The overarching aim for that program, was to develop 20-25% thrust growth over the F404 levels, without impacting the form-factor as much as possible (since the target platform is same, the SH E/F version).

Do note the basic phyzziks involved is,

Thrust = Mass-Flow x Diff of flow-velocity between the intake and exhaust

i.e. increase the Mass-Flow to get more Thrust - but the catch ofcourse is, increasing Mass-Flow is inversely proportionate to both thermal efficiency and TFC.

They went step-by-step:

i) the F-414 Fan was enlarged to ensure addn 16% mass-flow and the BPR was reduced to ensure larger mass-flow thru core - thus the enhanced mass-flow problem was solved.

ii) Then GE obviously had the hot-section tech depth and experience to ensure, higher TeT levels for the HPT (and the LPT), addressing the Thermal Efficiency (and overall efficiency) impact, arising due to this enhanced mass-flow.

iii) And, last but not the least, GE also had extensive technology wherewithal and experience wrt the transonic Compressor technology (read BLISKs in the first 3 HPC stages etc), so that they could ensure a matching higher OPR levels as well. The SFC "problem" also solved.

Now back to Kaveri Mk2 - in Ver 2(b), we have already tried sufficiently high TeT and matching high OPR levels, but still couldn't match the F414 thrust levels.

Thus, it's all but natural that we also try the exact route i.e. further increase the Mass-Flow, by increasing the inlet geometry.

So (pls refer to Rows 1-3), assumed a modest 12.5% increase in overall Mass-Flow, but since we want the Mass-flow thru the core to remain as same as before (some is unavoidable), so that the Gas-Generator CFD etc doesn't change too much, had to allow a higher BPR (same as that of F414) as well.

All this resulted in the Mass-Flow thru Core increased by a mere 4.4%.

With this new Overall Mass-Flow and new BPR, but with exact same TeT and OPR levels, went ahead modelling the Ver 3. And voila we are firmly in the F414 thrust realms.

Do note (pls refer to Rows 29 - 31), max/most of the resultant overall dry thrust increment is coming from the LPT-Fan/LPC combo, a direct result of increasing the BPR, and thus increasing the mass-flow quantity being bypassed (~7Kg/sec of the additional 9.75Kg/sec Mass-flow, is bypassed).

A few other interesting thing to observe (Pls refer to Rows 21 - 26):

i) Higher Work/Power requirement for both Fan/LPC and the HPC, indicates higher RPM for both (improving their PRs and their efficiencies)

ii) Higher Work extracted by the Combustor, is purely due to higher Stagnation Pressure built-up by the HPC stages (due to their higher PRs)

iii) Despite Fan/LPC combo sucking out addn Power/work to cater to additional mass-flow, still the Useful Work manages to slightly improve. This is due to addn work/power generated by the HP and LP turbines, again due to better match-up/correlation between the TeT, OPR and the mass-flow.

Also, all the efficiency figures (pls refer to Rows 32 - 35) shows significant improvement - it may sound a bit puzzling as:

i) how come Thermal Efficiency has gone up without any temp regime (read TeT) change.

Answer of course is with better co-relation of TeT with the OPR levels which results in increase in Useful Work (that is used to accelerate the mass-flow) without any significant addn Work from the Combustor.

etc etc.

I'll stop here/conclude my 4 part series - wrt step-by-step "evolutionary" aspects of graduating to F414 thrust levels by this so-called Kaveri Mk2 program.

Hope I've been able to bring-out/demo/illustrate the various nuances involved for such an endeavor, as much as I could, and I'm sure I must have missed a lot as well.

Do note, haven't deliberately gone into the Metallurgical and Material Sc aspects, as that would have made this series way too long.

Enter the Ver 3 ...

But before we get to it, let's briefly analyse at very very high level, what GE did to evolve the F404 TF to F414 levels.

The overarching aim for that program, was to develop 20-25% thrust growth over the F404 levels, without impacting the form-factor as much as possible (since the target platform is same, the SH E/F version).

Do note the basic phyzziks involved is,

Thrust = Mass-Flow x Diff of flow-velocity between the intake and exhaust

i.e. increase the Mass-Flow to get more Thrust - but the catch ofcourse is, increasing Mass-Flow is inversely proportionate to both thermal efficiency and TFC.

They went step-by-step:

i) the F-414 Fan was enlarged to ensure addn 16% mass-flow and the BPR was reduced to ensure larger mass-flow thru core - thus the enhanced mass-flow problem was solved.

ii) Then GE obviously had the hot-section tech depth and experience to ensure, higher TeT levels for the HPT (and the LPT), addressing the Thermal Efficiency (and overall efficiency) impact, arising due to this enhanced mass-flow.

iii) And, last but not the least, GE also had extensive technology wherewithal and experience wrt the transonic Compressor technology (read BLISKs in the first 3 HPC stages etc), so that they could ensure a matching higher OPR levels as well. The SFC "problem" also solved.

Now back to Kaveri Mk2 - in Ver 2(b), we have already tried sufficiently high TeT and matching high OPR levels, but still couldn't match the F414 thrust levels.

Thus, it's all but natural that we also try the exact route i.e. further increase the Mass-Flow, by increasing the inlet geometry.

So (pls refer to Rows 1-3), assumed a modest 12.5% increase in overall Mass-Flow, but since we want the Mass-flow thru the core to remain as same as before (some is unavoidable), so that the Gas-Generator CFD etc doesn't change too much, had to allow a higher BPR (same as that of F414) as well.

All this resulted in the Mass-Flow thru Core increased by a mere 4.4%.

With this new Overall Mass-Flow and new BPR, but with exact same TeT and OPR levels, went ahead modelling the Ver 3. And voila we are firmly in the F414 thrust realms.

Do note (pls refer to Rows 29 - 31), max/most of the resultant overall dry thrust increment is coming from the LPT-Fan/LPC combo, a direct result of increasing the BPR, and thus increasing the mass-flow quantity being bypassed (~7Kg/sec of the additional 9.75Kg/sec Mass-flow, is bypassed).

A few other interesting thing to observe (Pls refer to Rows 21 - 26):

i) Higher Work/Power requirement for both Fan/LPC and the HPC, indicates higher RPM for both (improving their PRs and their efficiencies)

ii) Higher Work extracted by the Combustor, is purely due to higher Stagnation Pressure built-up by the HPC stages (due to their higher PRs)

iii) Despite Fan/LPC combo sucking out addn Power/work to cater to additional mass-flow, still the Useful Work manages to slightly improve. This is due to addn work/power generated by the HP and LP turbines, again due to better match-up/correlation between the TeT, OPR and the mass-flow.

Also, all the efficiency figures (pls refer to Rows 32 - 35) shows significant improvement - it may sound a bit puzzling as:

i) how come Thermal Efficiency has gone up without any temp regime (read TeT) change.

Answer of course is with better co-relation of TeT with the OPR levels which results in increase in Useful Work (that is used to accelerate the mass-flow) without any significant addn Work from the Combustor.

etc etc.

I'll stop here/conclude my 4 part series - wrt step-by-step "evolutionary" aspects of graduating to F414 thrust levels by this so-called Kaveri Mk2 program.

Hope I've been able to bring-out/demo/illustrate the various nuances involved for such an endeavor, as much as I could, and I'm sure I must have missed a lot as well.

Do note, haven't deliberately gone into the Metallurgical and Material Sc aspects, as that would have made this series way too long.

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/ArenaJet/status/1756955289721393475?s=20 ---> Safran:

* Will set up a helicopter MRO facility with HAL in Goa by 2025.

* Will establish a LEAP Engine MRO facility in Hyderabad by 2025.

* Plans to triple its India workforce by 2026.

* Will continue innovating the Safran engines powering the Dassault Mirage 2000 and Rafale aircraft to support the Indian Air Force.

Source: https://aviationweek.com/mro/fast-5-saf ... -expansion

* Will set up a helicopter MRO facility with HAL in Goa by 2025.

* Will establish a LEAP Engine MRO facility in Hyderabad by 2025.

* Plans to triple its India workforce by 2026.

* Will continue innovating the Safran engines powering the Dassault Mirage 2000 and Rafale aircraft to support the Indian Air Force.

Source: https://aviationweek.com/mro/fast-5-saf ... -expansion

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/Defencematrix1/status/175 ... 91354?s=20 ---> Update on Gas Turbine Technology Development: DRDO's GTRE has issued tenders regarding the supply of 'Advanced Afterburner Components' made from advanced metal alloys (Haynes 188).

Representative picture of Kaveri Afterburner Nozzle.

Representative picture of Kaveri Afterburner Nozzle.

Re: Kaveri & Aero-Engine: News & Discussion

Alpha Defnse Hindi reporting news on Afterburner for Kaveri engine.

Feb 14, 2024

https://www.youtube.com/watch?v=sQ7JlMDTMSo

Feb 14, 2024

https://www.youtube.com/watch?v=sQ7JlMDTMSo

Re: Kaveri & Aero-Engine: News & Discussion

Not quite kaveri but an entrepreneur, Prateek Dhawan, dabbling in jet engines. He has created a 4 kg jet engine. He joined with Chirag Gupta, an ex-navy person and created DG engine company. Prateek Dhawan a mechanical engineer, has a masters degree from the US in combustion topics. He says creating a jet engine which runs is very different than having a engine which can run continuously for a long time. He is targeting high altitude UAVs.

DG engine is boot strapped with self funds. DG engines wants to scale up with materials available, they are not into multi-spool, single crystal engines. They are focused on small engines for the time being.

https://www.youtube.com/watch?v=_H9Es-H-mkU

DG engine is boot strapped with self funds. DG engines wants to scale up with materials available, they are not into multi-spool, single crystal engines. They are focused on small engines for the time being.

https://www.youtube.com/watch?v=_H9Es-H-mkU

Re: Kaveri & Aero-Engine: News & Discussion

From 2010-13 I was on a project in Dayton, OH (no brownie points on the relevance). During one of the annual air events, I ran into a Brit, who had "peddled" his jet engine in India (for civilians) and was on his way out because there were no takers in India. The Dhawan effort is similar to the Brit's (I still have very detailed photos). The point is that such efforts are way behind the curve (10-15 years), and therefore need an immediate infusion of funds to catch up.

Two days ago I contacted a number of my friends (all from MetSci). All had got their Ph. D. in MetSci, but in semiconductors (in the 80s), none in aero.

I would suggest GoI get in touch with that yak herder from Mongolia.

I have tried to get in touch with Dhawan (WRT "funds"),no response so far.. Correction, Prateek did get in touch. TBD.

The solution to "engine" is matching (to foreign) "funds". Got to go toe-to-toe with GE, P&W, RR, Safran, etc.

Two days ago I contacted a number of my friends (all from MetSci). All had got their Ph. D. in MetSci, but in semiconductors (in the 80s), none in aero.

I would suggest GoI get in touch with that yak herder from Mongolia.

I have tried to get in touch with Dhawan (WRT "funds"),

The solution to "engine" is matching (to foreign) "funds". Got to go toe-to-toe with GE, P&W, RR, Safran, etc.