Indian Manufacturing Sector

Re: Indian Manufacturing Sector

It was heartening to hear the prospects after the HSMC fiasco.

And that water and power crap always perplexed me ... for eg Mumbai doesn't have power cuts ... Can't India supply 24x7 power to an industry if we wanted to ... Ofcourse she can !

And that water and power crap always perplexed me ... for eg Mumbai doesn't have power cuts ... Can't India supply 24x7 power to an industry if we wanted to ... Ofcourse she can !

Re: Indian Manufacturing Sector

It looks like setting up a nuclear plant just to power it might make some sense. Nuclear plants don't create emissions either, vibrations not so sure.vcsekhar wrote: 1. Power, massive power in the range of multi Mega watts are required, this needs to be guaranteed interruption free. There is no way to provide a UPS for such an installation. This is something only a govt can guarantee in India, will require huge changes to how electricity is supplied to a private customer. The only place that I know of that has guaranteed power like this is the nuclear fuel complex in hyderabad, but, the power requirements will be a fraction in comparison.

And probably that's why the government is starting on the lower hanging fruits first like displays which have less stringent requirements

Re: Indian Manufacturing Sector

I am not sure if display fabs have any less stringent requirements, however, I am pretty sure that its not difficult to supply uninterrupted power to an industry, its already done as a matter of course all over the developed world every day. I would hazzard that 99.9% of people living in EU, US or Japan, Taiwan etc even have a UPS at home for their computers. It only requires a commitment by the power company and the govt to do so, having redundancy and proper planning is what is required.Dexter wrote: It looks like setting up a nuclear plant just to power it might make some sense. Nuclear plants don't create emissions either, vibrations not so sure.

And probably that's why the government is starting on the lower hanging fruits first like displays which have less stringent requirements

Obviously, Nuke power is very important for us to meet our green energy goals but its not necessary the answer for fabs.

I know from personal experience that we have spent huge amounts of money to cater for power failures in our factories for gensets and the required switchgear to automatically switch over but we still have to have UPS's for critical equipment. Unfortunately, high power equipment cannot be put on UPS's as that would be prohibitively expensive. All this was money that could have been better spent elsewhere for production or testing infrastructure but that is how it is over here.

we can always hope that the semiconductor push will also help raise the standards of power all around.

Re: Indian Manufacturing Sector

Oh really? How many Mosfet, thyristors, triacs, SCR, solid state relays, IGBT, etc. are being manufactured in India. I don't know if there are any, but I could be wrong though.Vayutuvan wrote: Not necessarily for power semiconductors. They tend to be big in terms of feature sizes. Switching range is also broader and at higher voltage levels.

Re: Indian Manufacturing Sector

Semiconductor Manufacturing: Swarajya Conversations On India’s $10 Billion Opportunity

short summary:

1. 10 billion sounds a lot for most industries but for semis it is not the case

2. focus needs to be on design startups, packaging and then tele communications

3. as this is a big investment of money, water and power providing very little employment experts remain skeptical of us establishing fabs

short summary:

1. 10 billion sounds a lot for most industries but for semis it is not the case

2. focus needs to be on design startups, packaging and then tele communications

3. as this is a big investment of money, water and power providing very little employment experts remain skeptical of us establishing fabs

Re: Indian Manufacturing Sector

Arent the fabs , even though expensive only a cog in the chain., isnt the whole ecosystem that develops around it worth the trouble.Atmavik wrote:Semiconductor Manufacturing: Swarajya Conversations On India’s $10 Billion Opportunity

short summary:

1. 10 billion sounds a lot for most industries but for semis it is not the case

2. focus needs to be on design startups, packaging and then tele communications

3. as this is a big investment of money, water and power providing very little employment experts remain skeptical of us establishing fabs

Re: Indian Manufacturing Sector

How does Taiwan provide power & water for it's fabs?

Just read they have 4 reactors.. which they are planning to phase out! Since every one is saying it requires tremendous power source, how will taiwan power the fabs in the future?

Just read they have 4 reactors.. which they are planning to phase out! Since every one is saying it requires tremendous power source, how will taiwan power the fabs in the future?

Re: Indian Manufacturing Sector

I don't know. What I am saying is that there is a need for power electronics/MMIC/High-frequency devices. IGFET is a more general MOSFET.csaurabh wrote:Oh really? How many Mosfet, thyristors, triacs, SCR, solid state relays, IGBT, etc. are being manufactured in India. I don't know if there are any, but I could be wrong though.

From Wikipedia page https://en.wikipedia.org/wiki/MESFET

As for the device geometries, see this.Applications

Numerous MESFET fabrication possibilities have been explored for a wide variety of semiconductor systems. Some of the main application areas are military communications, as front end low noise amplifier of microwave receivers in both military radar devices and communication, commercial optoelectronics, satellite communication, as a power amplifier for the output stage of microwave links, and as a power oscillator.

https://en.wikipedia.org/wiki/File:Power_die.svg

Re: Indian Manufacturing Sector

Vibrations? At what frequency and what power? I am not well versed but I can't think of any component of a nuc power plant causing vibrations. Do you mean EM?Dexter wrote:Nuclear plants don't create emissions either, vibrations not so sure.

Re: Indian Manufacturing Sector

more than the amount of power its the reliability.nam wrote:How does Taiwan provide power & water for it's fabs?

Just read they have 4 reactors.. which they are planning to phase out! Since every one is saying it requires tremendous power source, how will taiwan power the fabs in the future?

here is a ref to TSMC

https://www.youtube.com/watch?v=785Uzi1mGAA

Re: Indian Manufacturing Sector

How many plants does India need.. huge ! .. as a marker of index here is what China is., and where India is going to need

Re: Indian Manufacturing Sector

Thanks for the link. TSMC uses rainwater as a source! We have regions in the country which receive some of the the highest level of rains in the world. What technology does Taiwan uses that provides reliable power? The biggest source of power is coal & nuke. What is the big deal about them, that Taiwan can do it and we cannot? What stops us from building a dedicated power plant for a fab?more than the amount of power its the reliability.

here is a ref to TSMC

https://www.youtube.com/watch?v=785Uzi1mGAA

Hiranandhi opened up Asia's largest data center in 2020. A data center also requires 24/7 power. How do they manage it?

https://www.manufacturingtodayindia.com ... avi-mumbai

The most important aspect the video mentions is that 75% of the cost of a fab is actually the equipment. All other items mentioned is regular production headache, applicable to any plant.

Our biggest challenge is a trained workforce, missing ecosystem and justifying a return on investment. The first 2 is missing because of the 3rd problem.

So it is ALL about money. Nothing else.

Re: Indian Manufacturing Sector

It was in reponse to a post which said that a fab closed due to vibrations occurings from a road close by. The equipment could be very sensitive to minor vibrations as well ... I don't know for sureVayutuvan wrote: Vibrations? At what frequency and what power? I am not well versed but I can't think of any component of a nuc power plant causing vibrations. Do you mean EM?

Re: Indian Manufacturing Sector

Actually a little more than that ... As Ashwani Vaishnav put it ... A country which doesn't make semiconductors is gonna lose the race ... It's also about security and being in the gamenam wrote:So it is ALL about money. Nothing else.

Re: Indian Manufacturing Sector

We have to bite the bullet and get it done. It’s now or neverDexter wrote:Actually a little more than that ... As Ashwani Vaishnav put it ... A country which doesn't make semiconductors is gonna lose the race ... It's also about security and being in the gamenam wrote:

Re: Indian Manufacturing Sector

We are among the top 5 markets for cars, phones, pc's and a host of other electronics and growing every year. If semi conductor manufacturers can't be profitable in India, where can they? And they are one of the most expensive parts of any electronic device. Imagine the import bill that gets reduced.

Re: Indian Manufacturing Sector

Yes. They are very sensitive to vibrations beyond a certain magnitude. The threshold is tighter the smaller the feature size.Dexter wrote:It was in reponse to a post which said that a fab closed due to vibrations occurings from a road close by. The equipment could be very sensitive to minor vibrations as well ... I don't know for sure

Re: Indian Manufacturing Sector

Here Is Why Government Of India Is Trying For A JV To Modernise And Commercialise SCL Chip Fab In Chandigarh

https://swarajyamag.com/technology/here ... chandigarh

from the article.

If some sources are to be believed, certain reputed Indian business groups are already in discussion with the government and executives from one or more of them may have already visited SCL as well.

https://swarajyamag.com/technology/here ... chandigarh

from the article.

If some sources are to be believed, certain reputed Indian business groups are already in discussion with the government and executives from one or more of them may have already visited SCL as well.

-

Rishirishi

- BRFite

- Posts: 1409

- Joined: 12 Mar 2005 02:30

Re: Indian Manufacturing Sector

I am not against the semi conductor manufacturing, but I think a lot of people here equate manufacturing to value addition.hanumadu wrote:We are among the top 5 markets for cars, phones, pc's and a host of other electronics and growing every year. If semi conductor manufacturers can't be profitable in India, where can they? And they are one of the most expensive parts of any electronic device. Imagine the import bill that gets reduced.

The post above have a great picture explaining this. The value addition happens in the design development and supply of machines. The manufacturing itself is rather less value addition. In fact India is contributing to the design part.

If we want to move ahead in a meaningful way, India needs to create cities that are livable and attract talent to work there. As of now anyone with anything useful between the ears, move abroad. Places like BLR and Mumbai has good weather conditions. It should be possible to create worldclass cities here.

Places with sports facilities, good public transport, traffic, power and water, schools, roads, hospitals and without pollution. It is the golden opportunity that "everyone" seems to miss. In stead everyone seems to be hypnotized by mass manufacturing where jobs are boring, working conditions poor and pay bad.

Re: Indian Manufacturing Sector

Boring ?Rishirishi wrote:[quote="

Places with sports facilities, good public transport, traffic, power and water, schools, roads, hospitals and without pollution. It is the golden opportunity that "everyone" seems to miss. In stead everyone seems to be hypnotized by mass manufacturing where jobs are boring, working conditions poor and pay bad.

"Let them eat cake" said Marie-Antoinette french queen when people were begging for bread

Re: Indian Manufacturing Sector

What? A chip goes from being sand to 100 dollars value and much more. Is that not value addition?Rishirishi wrote:I am not against the semi conductor manufacturing, but I think a lot of people here equate manufacturing to value addition.hanumadu wrote:We are among the top 5 markets for cars, phones, pc's and a host of other electronics and growing every year. If semi conductor manufacturers can't be profitable in India, where can they? And they are one of the most expensive parts of any electronic device. Imagine the import bill that gets reduced.

The post above have a great picture explaining this. The value addition happens in the design development and supply of machines. The manufacturing itself is rather less value addition. In fact India is contributing to the design part.

Re: Indian Manufacturing Sector

https://swarajyamag.com/blogs/heres-wha ... m-in-india

Lots of good information in the above article

Lots of good information in the above article

-

Rishirishi

- BRFite

- Posts: 1409

- Joined: 12 Mar 2005 02:30

Re: Indian Manufacturing Sector

Unfortunately the contract manufacturer do not get the 100 dollars. The vast money go to mining, IP rights, design, machines and marketing. I do not know the exact figures, but essentially 90% of the people working in a FAB are low payed workers. It is not very different from making shoes or chewing gum. I am not against the effort. But am trying to point out that India needs to do better. Creating good cities that are nice to live in, is crucial for India to move on.What? A chip goes from being sand to 100 dollars value and much more. Is that not value addition?

Re: Indian Manufacturing Sector

I second what Rishirishi said. As a student of Electronic engineering in London in the late 1960s my studies moved from valves to semiconductors. While in my final year Intel announced their first DRAM (the 1103) and sshortly after the first micro processor the Intel 4004 which was the integration of a Japenese calculator chip.Rishirishi wrote:Unfortunately the contract manufacturer do not get the 100 dollars. The vast money go to mining, IP rights, design, machines and marketing. I do not know the exact figures, but essentially 90% of the people working in a FAB are low payed workers. It is not very different from making shoes or chewing gum. I am not against the effort. But am trying to point out that India needs to do better. Creating good cities that are nice to live in, is crucial for India to move on.What? A chip goes from being sand to 100 dollars value and much more. Is that not value addition?

The first Asian ventures into semiconductors were American assembly operations in Taiwan, Malaysia and the Philippines. The Japanese Under the guidance of their government department MITI (I think) made great strides in design and soon caught up with the US. Taiwan began to progress from pure assembly to design and manufacture of low end semis - the US was happy to let the Asian countries take on the low value components. It was about this time that Jerry Sanders, the founder of AMD said that semiconductors were the new "Oil Industry of the next century".

The Koreans now entered the race too driven by their urge to better their former colonial masters Japan, and made tremendous progress aided by some return of Korean engineers from the US and Japan. The Koreans were the largest minority in Japan and largely invisible once they lost their accents but were discriminated against when identified.

The Taiwanese moved up the food chain rapidly and soon equalled, and in some cases exceeded the US. The US gave up dominance of RAM, assembly and packaging to the Asians and concentrated on more complex LSI and elecricaly alterable designs. Europe was very much a backwater with just a few companies (some subsidiaries of US Companies) hanging on. Japan, like the US began to fadein the volume market but concentrate on high value niches.

This is very much the situation today. India could go down the Taiwan route where the government made a conscious effort to get the semi industry viable with funding of factories and a strong campaign to repatriate emigrant Chinese engineers from the US by creating similar environments in Taiwan (eg. Hinschu Science City). Many Chinese engineers, concerned by the high crime and drug rates in the US took the bait.

Or India can opt for the Malaysian option, much slower progression from assembly to moving up the skills chain to design.

India does not lack the talent. In my time in the industry, I initially dealt with mostly white engineers in the US (mostly California) and Europe. As time progressed, I noticed more and more Indian and Chinese engineers among the US and even European colleagues. I am including the Overseas Indians (mostly E. African) and Overseas Chinese (HK, Taiwan and Singapore) under this heading. Today most engineering courses in the UK are dominated by students or Asian (Indian, Pakistani and Chinese) origin.

Re: Indian Manufacturing Sector

MEIL's Drillmec to set up $200 million oil rig manufacturing hub in Telangana.

Drillmec SpA, a subsidiary of the city-based Megha Engineering and Infrastructures Limited (MEIL) group, will be setting up its global manufacturing hub in Telangana with an investment outlay of USD 200 million, a top executive of the Italian company said on Monday. Simone Trevisani, CEO, Drillmec and Jayesh Ranjan, Principal Secretary (Industries), Telangana government signed a MoU for the establishment of Drillmec International Hub for manufacturing oil rigs and ancillary equipment in the state.

"Drillmec SpA, a global leader in oil-drilling rigs manufacturing, is proposing to invest over USD 200 million in the upcoming facility for the setting up of the global hub, which would include manufacturing, research and development, and a Centre of Excellence to impart cutting-edge training to people," Trevisani said.

This manufacturing hub creates employment opportunities for around 2,500 people and the first rig from the facility is expected to roll out in the next nine months, he said.

Presently, Drillmec has manufacturing and assembling facilities in Italy, Belarus and USA. He said the company is currently having orders worth USD 1 billion on hand to be delivered in the next 24 months.

Drillmec clocked USD 220 million revenues during the last financial year and expects to earn USD 450-500 million this year, a senior executive of the company said.

Drillmec has so far delivered close to 600 drilling rigs and developed many innovative designs and acquired patents globally. The company, which was incorporated under the laws of Italy having its registered office at Podenzano PC, Italy, was acquired by MEIL group in 2020.

Drillmec SpA, a subsidiary of the city-based Megha Engineering and Infrastructures Limited (MEIL) group, will be setting up its global manufacturing hub in Telangana with an investment outlay of USD 200 million, a top executive of the Italian company said on Monday. Simone Trevisani, CEO, Drillmec and Jayesh Ranjan, Principal Secretary (Industries), Telangana government signed a MoU for the establishment of Drillmec International Hub for manufacturing oil rigs and ancillary equipment in the state.

"Drillmec SpA, a global leader in oil-drilling rigs manufacturing, is proposing to invest over USD 200 million in the upcoming facility for the setting up of the global hub, which would include manufacturing, research and development, and a Centre of Excellence to impart cutting-edge training to people," Trevisani said.

This manufacturing hub creates employment opportunities for around 2,500 people and the first rig from the facility is expected to roll out in the next nine months, he said.

Presently, Drillmec has manufacturing and assembling facilities in Italy, Belarus and USA. He said the company is currently having orders worth USD 1 billion on hand to be delivered in the next 24 months.

Drillmec clocked USD 220 million revenues during the last financial year and expects to earn USD 450-500 million this year, a senior executive of the company said.

Drillmec has so far delivered close to 600 drilling rigs and developed many innovative designs and acquired patents globally. The company, which was incorporated under the laws of Italy having its registered office at Podenzano PC, Italy, was acquired by MEIL group in 2020.

Re: Indian Manufacturing Sector

https://swarajyamag.com/news-brief/suzu ... components

Suzuki, Hyundai, Tata Motors, TVS, Kia, Bajaj, Ola Among 20 Companies Selected For ₹25,938-crore PLI Scheme For Auto And Auto Components

Suzuki, Hyundai, Tata Motors, TVS, Kia, Bajaj, Ola Among 20 Companies Selected For ₹25,938-crore PLI Scheme For Auto And Auto Components

Re: Indian Manufacturing Sector

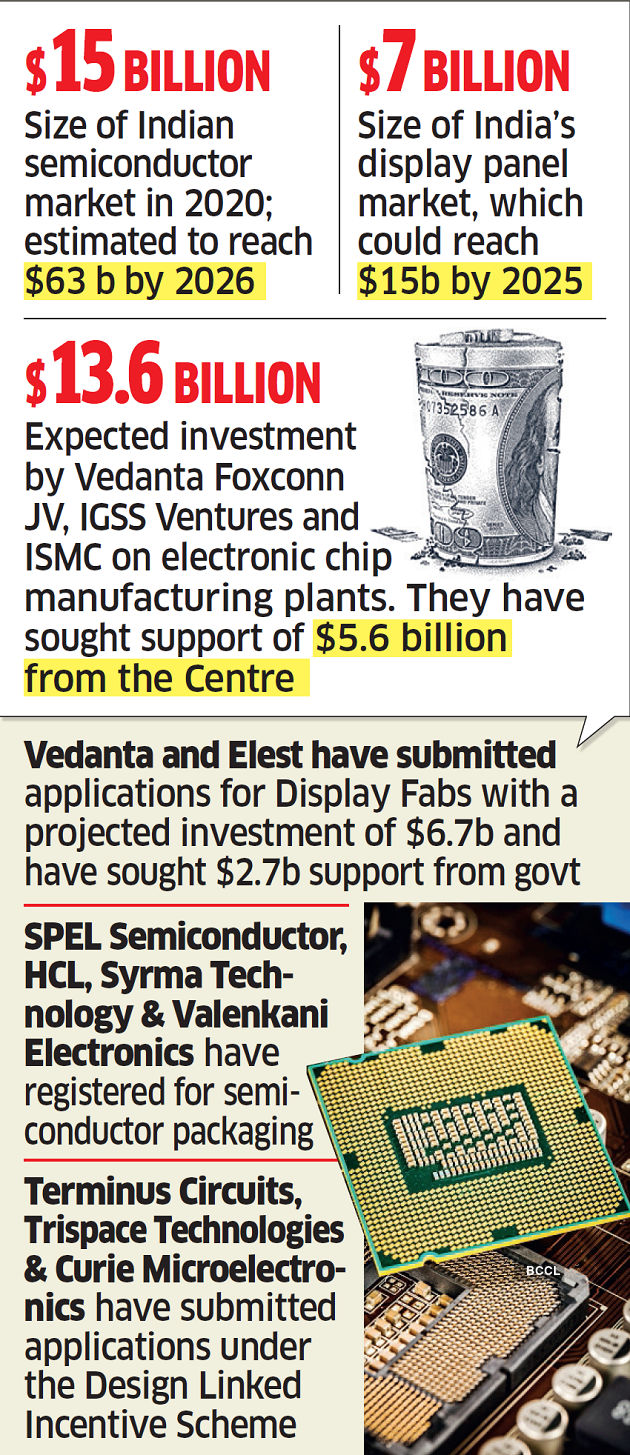

Five proposals worth $20.5-billion to set up chip, display fabrication units,

The Ministry of Electronics and Information Technology (MeitY), in a release, said it has received five applications for setting up of semiconductor fabrication and display fabrication units with total investment commitment of $20.5 billion (Rs 1.53 lakh crore).

For setting up of semiconductor fabrication units, proposals have been received from Vedanta, which has announced a joint-venture with Foxconn, IGSS Ventures, which is a Singapore-based company, and ISMC, which is led by Next Orbit Ventures Fund, the ministry said on Saturday.

“The applications have been received for setting up 28 nm (nanometer) to 65 nm semiconductor fabs with capacity of approx 120,000 wafers per month and the projected investment of $13.6 billion wherein fiscal support from the central government is being sought for nearly $5.6 billion,” it added.

For setting up of display fabrication units, two applications have been received from Vedanta and Elest, with total investment commitment of $6.7 billion and the fiscal support sought from the government could be up to $2.7 billion, the MeitY said.

Last December, the Cabinet had approved a Rs 76,000-crore plan for semiconductor and display manufacturing ecosystem in the country. As a part of the plan, the Centre has lined up incentive support for companies engaged in silicon semiconductor fabs, display fabs, compound semiconductors, silicon photonics, sensors fabs, semiconductor packaging and semiconductor design.

As a part of the scheme, for setting up of silicon complementary metal oxide semiconductor, fabrication units that manufacture technology node of 28 nm or lower will get up to 50 per cent of the project cost as incentive, while for above 28 nm but up to 45 nm, the Centre will provide 40 per cent of the unit cost.

The government’s move to incentivise setting up of semiconductor fabrication units assumes significance at a time when there is a global shortage of semiconductor products. Further, for setting up of semiconductor assembly, testing, marking and packaging units, four companies — SPEL Semiconductor, HCL, Syrma Technology and Valenkani Electronics — have submitted applications; meanwhile, Ruttonsha International Rectifier submitted application under the semiconductor scheme for manufacturing of compound semiconductors.

Earlier this week, The Indian Express reported that the Centre was targeting 2024 for the formal opening of India’s first semiconductor fabrication unit. The nod for at least one major company among three that have applied, is likely to come before March 31.

The Ministry of Electronics and Information Technology (MeitY), in a release, said it has received five applications for setting up of semiconductor fabrication and display fabrication units with total investment commitment of $20.5 billion (Rs 1.53 lakh crore).

For setting up of semiconductor fabrication units, proposals have been received from Vedanta, which has announced a joint-venture with Foxconn, IGSS Ventures, which is a Singapore-based company, and ISMC, which is led by Next Orbit Ventures Fund, the ministry said on Saturday.

“The applications have been received for setting up 28 nm (nanometer) to 65 nm semiconductor fabs with capacity of approx 120,000 wafers per month and the projected investment of $13.6 billion wherein fiscal support from the central government is being sought for nearly $5.6 billion,” it added.

For setting up of display fabrication units, two applications have been received from Vedanta and Elest, with total investment commitment of $6.7 billion and the fiscal support sought from the government could be up to $2.7 billion, the MeitY said.

Last December, the Cabinet had approved a Rs 76,000-crore plan for semiconductor and display manufacturing ecosystem in the country. As a part of the plan, the Centre has lined up incentive support for companies engaged in silicon semiconductor fabs, display fabs, compound semiconductors, silicon photonics, sensors fabs, semiconductor packaging and semiconductor design.

As a part of the scheme, for setting up of silicon complementary metal oxide semiconductor, fabrication units that manufacture technology node of 28 nm or lower will get up to 50 per cent of the project cost as incentive, while for above 28 nm but up to 45 nm, the Centre will provide 40 per cent of the unit cost.

The government’s move to incentivise setting up of semiconductor fabrication units assumes significance at a time when there is a global shortage of semiconductor products. Further, for setting up of semiconductor assembly, testing, marking and packaging units, four companies — SPEL Semiconductor, HCL, Syrma Technology and Valenkani Electronics — have submitted applications; meanwhile, Ruttonsha International Rectifier submitted application under the semiconductor scheme for manufacturing of compound semiconductors.

Earlier this week, The Indian Express reported that the Centre was targeting 2024 for the formal opening of India’s first semiconductor fabrication unit. The nod for at least one major company among three that have applied, is likely to come before March 31.

Re: Indian Manufacturing Sector

Only TSMC and Samsung have program and working towards setting up 3 NM Fab.

Re: Indian Manufacturing Sector

In DRAMs SKHyinx is also a player. They have 14 nm and 10nm fabs.

Re: Indian Manufacturing Sector

https://omdia.tech.informa.com/OM016176 ... five-years [nov 20]

The wafer planar process can be most cost-effective at 28nm. For the subsequent 16/14nm requiring FinFET process, the cost of wafer manufacturing will increase by at least 50%. Only applications with huge volumes such as mobile phones can absorb the cost. In many related non-consumer applications, 28nm offers good value for money for its balance between reliability, performance, and cost.

After 2017, although the application of 28nm technology in the mobile area declined, its applications in other fields such as OTT boxes and smart TVs increased rapidly.

OLED drivers

With the improvement of mobile phone configuration and the continuous growth of global OLED panel production capacity, OLED growth will drive demand for OLED drivers. Currently, OLED drivers come mainly from Korean manufacturers. 28nm will become the mainstream for high-end OLED drivers in the next three to five years

Connectivity chips

The explosion of IoT applications and traditional home appliance upgrades is driving demand for wireless connections such as Wi-Fi and Bluetooth from various devices. At present, the mainstream wireless connection technologies are migrating to 28nm. Future upgrades of industrial and consumer products will inevitably drive high demand for wireless connection.

FPGA

FPGA has a huge space in various proprietary application areas, such as hybrid computing centers, wireless base stations, and autonomous vehicles, in which the 28nm process, featuring high performance and low power consumption, is an ideal option.

Edge computing

There is growing demand for the combination of cloud and edge and local edge computing. At present, edge computing generally has basic artificial intelligence analysis capabilities. 28nm has its advantage in this kind of scenario requiring relatively strong local data collection and preliminary logic computing capabilities.

NB-IoT, LoRA, Cat.1, eMTC

SoC chips conforming to commonly used IoT protocols are mainly on 28nm, which will continue to be the mainstream choice for a long time.

Emerging applications and market trends in the next five years

Hardware upgrades of mobile phones, the rise and popularization of Internet of Things, and more emerging applications in recent years are giving birth to the next period of strong demand for 28nm.

The wafer planar process can be most cost-effective at 28nm. For the subsequent 16/14nm requiring FinFET process, the cost of wafer manufacturing will increase by at least 50%. Only applications with huge volumes such as mobile phones can absorb the cost. In many related non-consumer applications, 28nm offers good value for money for its balance between reliability, performance, and cost.

After 2017, although the application of 28nm technology in the mobile area declined, its applications in other fields such as OTT boxes and smart TVs increased rapidly.

OLED drivers

With the improvement of mobile phone configuration and the continuous growth of global OLED panel production capacity, OLED growth will drive demand for OLED drivers. Currently, OLED drivers come mainly from Korean manufacturers. 28nm will become the mainstream for high-end OLED drivers in the next three to five years

Connectivity chips

The explosion of IoT applications and traditional home appliance upgrades is driving demand for wireless connections such as Wi-Fi and Bluetooth from various devices. At present, the mainstream wireless connection technologies are migrating to 28nm. Future upgrades of industrial and consumer products will inevitably drive high demand for wireless connection.

FPGA

FPGA has a huge space in various proprietary application areas, such as hybrid computing centers, wireless base stations, and autonomous vehicles, in which the 28nm process, featuring high performance and low power consumption, is an ideal option.

Edge computing

There is growing demand for the combination of cloud and edge and local edge computing. At present, edge computing generally has basic artificial intelligence analysis capabilities. 28nm has its advantage in this kind of scenario requiring relatively strong local data collection and preliminary logic computing capabilities.

NB-IoT, LoRA, Cat.1, eMTC

SoC chips conforming to commonly used IoT protocols are mainly on 28nm, which will continue to be the mainstream choice for a long time.

Emerging applications and market trends in the next five years

Hardware upgrades of mobile phones, the rise and popularization of Internet of Things, and more emerging applications in recent years are giving birth to the next period of strong demand for 28nm.

Re: Indian Manufacturing Sector

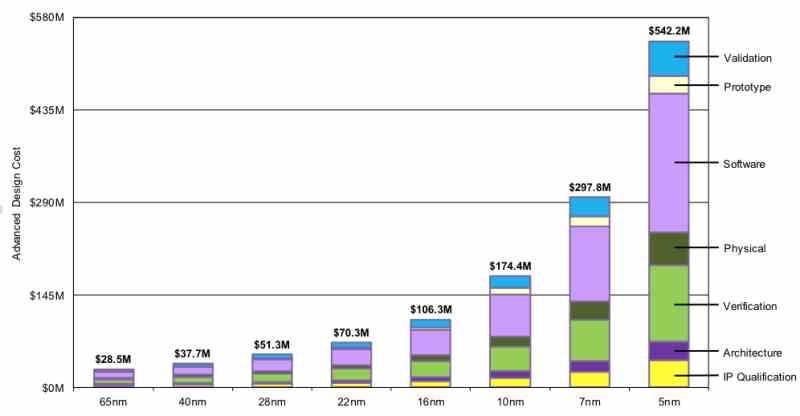

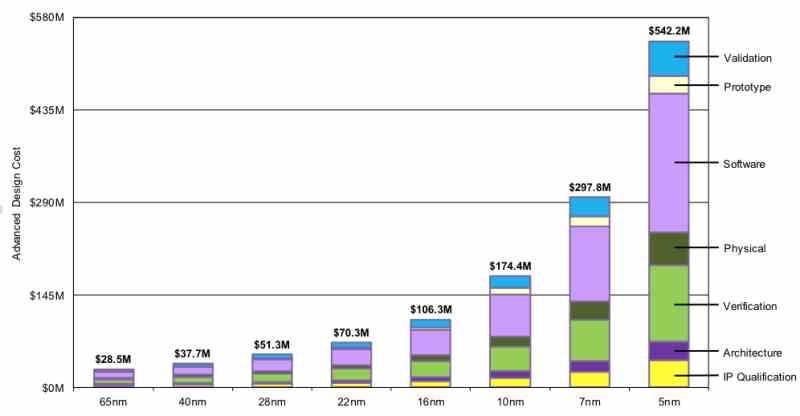

Chip Design costs

Re: Indian Manufacturing Sector

Great graphic. Source please. Is there an article along with this graphic somewhere (on techunwrapperd?)

Re: Indian Manufacturing Sector

Big Trouble At 3nmVayutuvan wrote:Great graphic. Source please. Is there an article along with this graphic somewhere (on techunwrapperd?)

Edit: the data came from IBS but can't find the graphic there. Just plain data

Re: Indian Manufacturing Sector

Adding it here

Re: Indian Manufacturing Sector

Data is even better. Thanks.m_saini wrote: Big Trouble At 3nm

Edit: the data came from IBS but can't find the graphic there. Just plain data

Re: Indian Manufacturing Sector

https://irds.ieee.org/editions/2021

old reports are available. My guess is that 28 - 32 nm would have been described in 2017 or so. ITRS-2 stopped functioning in 2015. Roadmaps from 2016 onwards are here at this site.

FYI

These roadmap reports are free. You have to create an account with an email id. Gmail works fine. IEEE membership is not required.What Is the IRDS™?

From Moore’s Law to NTRS to ITRS to IRDS™

The semiconductor industry has a unique distinction among all the industries of having begun with a roadmap. In most cases an industry roadmap is initiated only when that industry requires a major revolutionary revision that departs from the way such industry had operated for decades.

In 1965 Gordon Moore mapped the future of the semiconductor industry before such an industry even existed (Electronics, Volume 38, Number 8, April 19, 1965). The semiconductor industry grew and diversified in the subsequent decades and it was not until 1991 that the US semiconductor community decided to formulate a 200-page document detailing all the aspects of the industry. In the meantime the semiconductor community had expanded to other regions and therefore it became clear that a broader world-wide approach to roadmapping needed to be taken.

The ITRS (or International Technology Roadmap for Semiconductors) was produced annually by a team of semiconductor industry experts from Europe, Japan, Korea, Taiwan and the US between 1998 and 2015. Its primary purpose was to serve as the main reference into the future for university, consortia, and industry researchers to stimulate innovation in various areas of technology.

A handful of these areas include:

Process integration, devices, and structures

System drivers and design

Factory integration

Microelectromechanical systems

Emerging research devices

Emerging research materials

IC interconnects

In 2005 the ITRS published the first white paper where the terms “More than Moore” (MtM) and “More Moore” (MM) were introduced for the very first time.

old reports are available. My guess is that 28 - 32 nm would have been described in 2017 or so. ITRS-2 stopped functioning in 2015. Roadmaps from 2016 onwards are here at this site.

FYI