This from SpaceX https://www.flickr.com/photos/spacex/27028105566/:

Origin

BROOMFIELD, Colorado—The Blue Origin New Shepard reusable suborbital launch system has joined NASA’s stable of rides to space and near-space for experiments under its Flight Opportunities Program (FOP), marking another step toward a return on owner Jeff Bezos’ substantial investment in the commercial spaceflight company.

Blue Origin is now able to compete for FOP missions under the agency’s $45 million indefinite-delivery, indefinite-quantity effort to provide access to space for experiments that meet the needs of NASA and other government agencies, including scientific experiments and spaceflight demonstrations designed to raise the readiness levels of new technologies. Five other companies are in the FOP catalog.

“Adding additional flight providers enables NASA and the broader aerospace community to demonstrate and transition space technologies, developing new capabilities faster and, potentially, at lower cost,” said Steve Jurczyk, associate administrator for NASA’s Space Technology Mission Directorate, which funds the program.

[CHARTBEAT:3]

Ericka Wagner, Blue Origin’s business development manager, outlined the flight services the company is offering on New Shepard for an audience of potential customers at the Next-Generational Suborbital Researchers Conference here. For prices ranging from $50,000 to $100,000 for a single standardized payload locker, the company will help researchers prepare their experiments for flight and send them above the 100-km (62-mi.) Karman line denoting the edge of space for a little less than four minutes of microgravity. Recovery will follow via parachute and a retro-thruster near the vehicle’s launch pad in West Texas.

The company plans to fly FOP payloads, and others, as it works through a series of unmanned test flights that it hopes will lead to crewed flight tests next year, and commercial flights with as many as six paying passenger on board in 2018. In addition to planning for human flights by tourists or researchers, Blue Origin is offering a 60-page payload user’s guide containing information on interfaces, flight loads and the government paperwork that must be completed before an experiment can fly.

In its most recent flight tests—all reusing the same vertical takeoff and landing propulsion module and BE-3 cryogenic engine—the company has flown some simple pathfinder payloads for outside researchers who flew for free. That will change under NASA’s FOP and other new business as the once-secretive company continues to open its doors to paying customers, adding services as it learns more about how the vehicle operates.

The next flight test, also with the same booster, is like to come “soon,” according to Brett Alexander, Blue Origin’s director of strategy and business development. It will push the envelope in tilting the booster to fly back to its landing site, and may wind up destroying the vehicle, he said. Any payloads flying in the capsule should be recovered intact, since it separates and continues to coast upward while the booster begins to descend.

NanoRacks, which provides payload accommodation on the International Space Station and designed the payload accommodation for Virgin Galactic’s suborbital SpaceShipTwo, has developed a standardized locker for the New Shepard under contract to Blue Origin. The hardware can hold 12 2U CubeSat-equivalent experiments, and can also work on the ISS for experiments that get a trial run on the suborbital vehicle before moving on to the orbital outpost, according to Carl Carruthers Jr., NanoRacks chief scientist.

Blue Origin joins Virgin Galactic, Masten Space Systems, UP Aerospace, Near Space Corporation and World View Enterprises in NASA’s FOP catalog. The first three companies provide rocket flights to suborbital space, while the last two offer high-altitude balloon missions to the stratosphere for experiments designed for that environment.

Peter B. de Selding @pbdes 12:31 AM - 9 Jun 2016

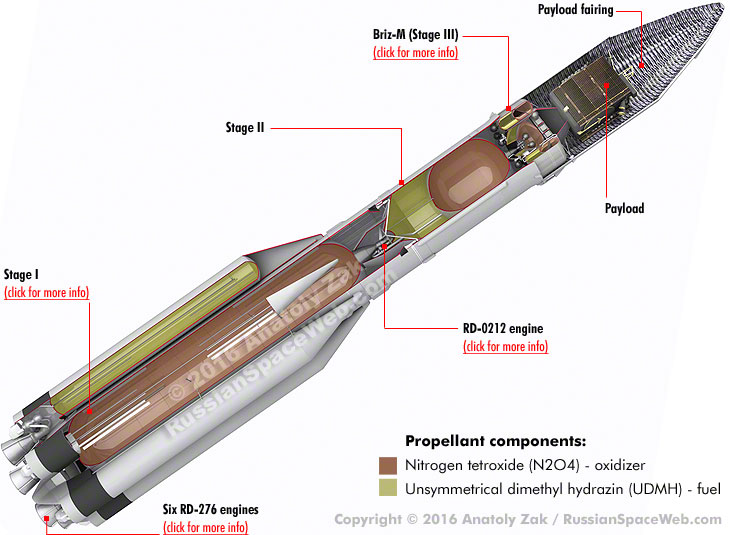

Today's Proton launch is 1st for the vehicle's Phase 4 upgraded version, which adds 150 kg to Proton's performance to GTO.

Peter B. de Selding @pbdes 12:33 AM - 9 Jun 2016

ILS VP John Palme: Proton Phase 4 upgrade = lighter-weight, high-strength metallic structures & high-precision tooling for optimized design.

Peter B. de Selding @pbdes 12:37 AM - 9 Jun 2016

Why upgrade Proton w/ new-generation Angara family waiting in wings? Because Proton rocket'll remain active for another decade, ILS says.

Sierra Nevada Corp. is using its multibillion-dollar NASA contract to deliver cargo to the International Space Station (ISS) as a marketing starting gun aimed at selling its Dream Chaser lifting-body vehicle for missions throughout the emerging low-Earth-orbit economy and beyond.With its selection as a third cargo carrier in NASA’s $14 billion, second-round Commercial Resupply Services competition, the privately held aerospace company is pushing Dream Chaser into the international marketplace and mapping its route into the future.

“There’s an existing market, which is the ISS,” says John Olson, vice president for exploration systems in the company’s Space Systems unit. “There’s an emerging market, which is near-term. With kits or no changes, we can capture those markets. Likewise, looking at the growth market and extending out with crewed and on-orbit servicing, and a litany of others, that’s really the big paradigm that we’re driving at.”

And it is a big paradigm indeed. In a presentation at the fifth Next-generation Suborbital Researchers Conference (NSRC) near the company’s office-park space-hardware factory in Louisville, Colorado, Olson reiterated the advantages of Dream Chaser and gave a taste of what it can do for space researchers who later came over from the NSRC for a tour.“The killer app is coming back at a G and a half in its reentry profile,” he explained of the loads that experiments will experience when Dream Chaser glides to a runway touchdown pretty much anywhere a Boeing 737 or an Airbus A320 can land.

That appeals to scientists and engineers who do not want delicate samples created in microgravity to be scrambled on landing by the higher G loads on the commercial capsules. Also attractive to researchers is the free-flying module for pressurized and unpressurized cargo that will ride behind the Dream Chaser lifting body like a utility trailer (see illustration).The cargo module will be left behind when the lifting body reenters to land and is designed to burn up in the atmosphere with as much as 3,250 kg (7,165 lb.) of space station trash inside and another 1,500 kg of unpressurized junk attached to the outside with standard ISS flight-releasable attachment mechanisms usually called “Frams.”

NASA is finding uses for cargo vehicles bound for destruction after they leave the ISS, such as the series of potentially dangerous flame-propagation experiments set for the Orbital ATK Cygnus vehicle. The 15-ft.-long Dream Chaser cargo module has its own solar arrays and can use the power they generate to serve the same extended-mission function, according to John Roth, vice president for business development.

“I can certainly use that,” said one NASA space-science manager on the factory tour, citing the difficulty of finding accommodation and crew time on the space station for experiments that do not meet the agency’s commercialization and exploration-technology priorities.

Olson calls the NASA contract a “stamp of approval” that opens the door for expanded marketing. Dream Chaser is launch-vehicle agnostic, designed to fly on the United Launch Alliance (ULA) Atlas V but also compatible with the ULA Delta IV, Europe’s planned Ariane 6, Japan’s H-III upgrade scheduled for operations in 2020 and the SpaceX Falcon Heavy.

The NASA contract does not call for Dream Chaser cargo missions until 2019 at the earliest, so the vehicle also will be compatible with ULA’s planned Vulcan launcher along with either the Blue Origin BE-4 or Aerojet Rocketdyne AR-1 main-stage engines now in competition for the job, according to Olson.

“NASA being the anchor tenant [indicates] a minimum of six missions, and as we build a minimum of two vehicles that have a design life of 15 times over 10 years, that means there’s 30 flights in those two vehicles alone,” Olson says. “And if NASA uses a minimum of six of those, that’s 24 flights where we own the vehicle and aim to fly it quite regularly in that time.”

Originally, Dream Chaser was developed as the Sierra Nevada entry in NASA’s commercial-crew competition, losing out to the capsules proposed by Boeing and SpaceX. The atmospheric test vehicle set for more drop-testing at Edwards AFB, California, later this year still has windows (and the pair of fuzzy dice hanging in them that flew on the first drop test), but the cargo version will eliminate the heavy glass to save weight for launch.

Olson says there is extensive commonality between the crewed and uncrewed variants, and the company plans to complete development of the human-rated version when the business case warrants. On March 28, Sierra Nevada held an airport workshop in Huntsville, Alabama, the site of one of the six facilities the company may contract for landing both variants. The others are Houston Ellington Spaceport, Midland (Texas) Spaceport, Jacksonville (Florida) Cecil Spaceport, Wallops Flight Facility in Virginia and Prestwick Airport in Scotland.

Launching Dream Chaser on an expendable rocket will require the same air-traffic safety constraints as any other liftoff from Cape Canaveral or elsewhere, but the company believes the return to Earth will be a different scenario that adds further flexibility to its system.

“When we interface with the National Aerospace System, we’re a very quick entry and pass through,” says Olson, noting the Dream Chaser will go from 100,000 ft. to wheels-stop in less than 3.5 min.

WASHINGTON: The US military successfully targeted and destroyed a moving truck from a drone using the missile designed to replace the venerable Hellfire.

The Joint Air To Ground Missile (JAGM) was fired May 25 at a truck traveling at 20 mph from a Grey Eagle drone at Dugway Proving Ground, Utah. The truck was hit and destroyed. Col. James Romero, with the Army’s Missiles and Space Program Executive Office, said the missile flew a bit farther than 8 kilometers at a “nominal altitude.”

This was the missile’s seventh test but the first time it was fired from a drone. It’s already been tried on Army Apaches and the Marine Corps Cobra helicopters.

JAGM was originally developed to replace the Maverick on the Navy F/A-18E/F Super Hornet, as well as the Hellfire and missiles on the Army’s AH-64D Apache attack helicopter, the Army’s Extended Range Multi-Purpose Sky Warrior drone (which became the Grey Eagle), the Marine’s AH-1Z Super Cobra attack helicopter, and the Navy’s MH-60R Seahawk.

It’s now meant only to replace the Hellfire and some TOW missiles, so the program’s value, which industry sources had pegged at somewhere around $5 billion, may be lower — though it’s hard to tell.

The Army will test JAGM for safety and lethality starting in August. Romero said they’ll be aiming to get air worthiness certificates so they can be deployed on the helicopters.

Lockheed won, unopposed, the $66 million JAGM missile Engineering and Manufacturing Development contract last summer.

Boeing anticipates an extension of its F/A-18E/F Super Hornet and EA-18G Growler production lines as a result of an increased operational tempo by the US Navy (USN) and strong international interest in procuring the platform, company officials told reporters on 10 June.Speaking at Boeing's Global Sustainment and Support (GS&S) site at Cecil Field in northern Florida, Dan Gillian, Vice President of the F/A-18 and EA-18G programmes, said that, with the USN burning through airframe hours at a far higher rate than originally intended and with additional exports expected in the near term, the company is confident of extending production from the current mid-2018 cut-off point through into the next decade.

"I believe that we will continue to build new Hornets and Growlers. We have slowed production down to two aircraft per month, and we will keep it at that level through to mid-2018. There is strong domestic and international demand that we see sustaining production through to the mid-2020s," Gillian said.

The US Navy's current programme of record is for 568 Super Hornets and 160 Growlers. As Gillian noted, however, the service has identified a 'Super Hornet shortfall' that will materialise in the 2030s/2040s as aircraft prematurely reach the end of their 6,000 hour airframe lives owing to the high operational tempo being flown today. To try and mitigate this, additional aircraft have already been requested in the fiscal year defence budget, and Gillian expressed his confidence that these will be approved.

On the international front, Gillian noted that a deal with Kuwait is currently going through the Foreign Military Sales (FMS) process with the US government and should be finalised in the not-too-distant future. Current legacy Hornet operator Finland has issued a request for proposals (RfP) that Boeing is preparing its response to, as has Belgium. Spain, which also now flies the Hornet, is in the early stages of a fighter procurement project for which Boeing will bid the Super Hornet, while India and Canada are being offered the platform to fulfil their respective requirements also.

With the Super Hornet and Growler set to remain in US Navy service through to the 2040s at least, and with a development roadmap put in place by Boeing, Gillian said that prospective future customers should have no concerns about the long-term viability of the platforms.With the Super Hornet and Lockheed Martin F-35C Lightning II Joint Strike Fighter (JSF) expected to serve alongside one another with the USN for several decades to come, the service plans to roll out a service-life extension plan (SLEP) for the former as part of wider plans to ensure that there are no capability gaps caused by a drop in aircraft numbers as older Super Hornets reach the end of their service lives and the delayed JSF begins entering fleet service.

As well as the SLEP, the Pentagon's fiscal year (FY) 2017 budget proposal will request up to 28 additional Super Hornets to try to offset any shortfall in the number of strike fighters available on the navy's aircraft carriers.

Coupled with this USN sustainment and support, Boeing has developed its Advanced Hornet roadmap that includes enhancements such as conformal fuel tanks, a large area display cockpit, more powerful engines, and an integrated infrared search and track (IRST) sensor.

Although all of these measures should go a long way to demonstrating both the navy's and Boeing's long-term commitment to the platform, the problem for the Super Hornet will really be in stemming the momentum of the F-35 with its fifth-generation capabilities. Boeing recently lost out to its competitor in Denmark, and the company is awaiting an explanation from the Danish government as to how it reached its decision. If Boeing is to maintain Super Hornet production out to the mid-2020s as it intends, it will have to hope that the Danish result was a blip rather than a trend.

http://nextbigfuture.com/2016/06/spacex ... ustry.htmlThe broader Raptor concept "is a highly reusable methane staged-combustion engine that will power the next generation of SpaceX launch vehicles designed for the exploration and colonization of Mars"

Recognizing that new, autonomous and survivable unmanned aircraft will not emerge soon, DARPA has selected Lockheed Martin and Raytheon to lead development of the ability to add autonomous behaviors to existing UAVs so they can collaborate in performing missions in contested environments.

The companies have been selected as system integrators for Phase 2 of the Collaborative Operations in Denied Environment (CODE) program. This aims to enable legacy U.S. UAVs to engage mobile ground or maritime targets in contested electromagnetic airspace while reducing required communications bandwidth and operator workload.

“The concept is to create heterogeneous teams of unmanned aircraft,” says Jean-Charles Lede, DARPA program manager. “Instead of adding sensors, we compose new teams. If we want electronic warfare, we add a jamming bird. If it is strike, we add a weapons platform. CODE enables UAVs to be mixed to do missions we were not able to before.”

CODE’s main objective is to demonstrate collaborative autonomy, in which UAVs perform sophisticated tasks both individually and in teams under the supervision of a single human mission commander. CODE-equipped UAVs would share data, negotiate assignments, and synchronize actions and communications among team members and with the commander.

Phase 1 simulations demonstrated the potential value of collaborative autonomy at the tactical edge, says DARPA. “Between the two teams, we have selected about 20 autonomous behaviors that would greatly increase the mission capabilities of our legacy UAVs and enable them to perform complex missions in denied or contested environments in which communications, navigation, and other critical elements of the targeting chain are compromised,” says Lede.

CODE’s main objective is to demonstrate collaborative autonomy, in which UAVs perform sophisticated tasks both individually and in teams under the supervision of a single human mission commander. CODE-equipped UAVs would share data, negotiate assignments, and synchronize actions and communications among team members and with the commander.

Phase 1 simulations demonstrated the potential value of collaborative autonomy at the tactical edge, says DARPA. “Between the two teams, we have selected about 20 autonomous behaviors that would greatly increase the mission capabilities of our legacy UAVs and enable them to perform complex missions in denied or contested environments in which communications, navigation, and other critical elements of the targeting chain are compromised,” says Lede.

The focus is on Group 3 tactical UAVs and above, operating in jamming environments. “All collaborative algorithms focus on a set of assumptions including guaranteed communications and infinite bandwidth. We are breaking those assumptions,” he says. “The algorithms have to work with 50 kbps. That is very, very low compared with full-motion video.”

The program has four technology pillars, says Lede, with sufficient single-vehicle autonomy as the starting point. This includes autonomous management of platform subsystems. “Instead of sending all the data, we want to send only relevant data, such as ‘I am here and my health is good’ or ‘I have found a target, here is an image chip,’” he says.

Next is a human-system interface enabling supervisory control of a large group of unmanned aircraft. “It is about how to enable the human to provide objectives in a complex environment, set the rules of engagement, and review the mission plan in temporal, logical and spacial terms, in real time,” Lede says. “We need the smarts of a human.”

The third pillar is team-level collaborative autonomy. This involves developing algorithms that permit the fusing of data from multiple sources to create a common operating picture and enable common decision-making among the UAVs, allowing them to compose subteams to achieve mission objectives. “Attrition is a complicating factor,” he says. “How do we accommodate going from six to four aircraft?”

In the example given by DARPA, the mission commander circles a group of UAVs on a display to create a team and assign it to search an area. The software then divides the search task up among the aircraft and, if assets are lost, redistributes the original tasks among the remaining aircraft. The goal is to simplify command and control of large groups of UAVs.

The fourth pillar is open-architecture systems. “Autonomy is different to other Defense Department technologies, like stealth or warheads, in which few are able to be involved. It is an activity anyone can contribute to. Two guys in an office can come up with something,” says Lede. “We want to enable a rich community to collaborate.”

Phase 1 involved three system integrators (Leidos did not make it through to Phase 2) and seven software developers, and took CODE to a preliminary design review. Phase 2 will take the technology to a critical design review and early single-vehicle flight demonstration by mid-2017 using a surrogate platform. Six software developers from Phase 1 will provide supporting technologies to the system integrators.

Following a down-select scheduled at the end of the yearlong second phase, the planned Phase 3 will complete software development and culminate in a full live-virtual-constructive mission demonstration using six or more real vehicles and others that are simulation. CODE is scheduled to be completed by the end of fiscal 2018.

Phase 1 simulations show CODE in action. 1: commander groups UAS into mission teams. Credit: DARPA

2: CODE-enabled UAS collaborate via low-bandwidth communications to perform assigned mission. Credit: DARPA

3: UAS use network communications for relative navigation in a GPS-denied environment. Credit: DARPA

4: Individual UAS perform and share feature-based navigation in GPS-denied environment. Credit DARPA

The SM-3 is a kinetic energy warhead able to travel more than 600 miles per hour; it carries no explosive but instead relies on the sheer force of impact and collision to destroy an enemy target.

The new SM-3IIA missile builds upon a smaller existing operational variant of the missile called the SM-3IB, Raytheon officials said.

“This is an extended capability of what we have for the SM-3 1B. Because of the larger missile this is a 21-inch air frame. we have a larger area of defended area coverage. we've also brought in some capability advancements into our kinetic warhead so now we have a higher sensitivity - so that is just better seeker,” Amy Cohen, Raytheon SM-3 Director, told Scout Warrior in an interview.

The SM-3IIA is still finishing up development and is slated for flight test in the second half of this year. The MDA and Raytheon test will assess the kinetic warhead and missile seeker in a space environment, Cohen explained.

An improved seeker can better see approaching targets from longer distances compared to the SM-3 1B, she added.

Some of these improvements engineered into the missile are described as “sensitivity increases” which use a larger focal plane array for detection and more computer processing power.

The SM-3 Block IIA has completed two very successful fly-out tests—with no target missile launched, Missile Defense Agency officials said.

“The first intercept flight test is planned for second half of this year. We will be engaging against a medium range ballistic missile - the next flight test we have will get us to the point where we have the trajectory very solid that we are there to support EPAA phase III in Poland,” Cohen added.

Artificial intelligence (AI), or at least algorithmic capabilities that come under that heading, are coming to the cockpit to help combat pilots assimilate the growing flow of information from sensors onboard and offboard their aircraft. DARPA’s Target Recognition and Adaption in Contested Environments (TRACE) program is using recent advances in machine learning to automatically locate and identify targets in synthetic-aperture radar (SAR) images. The goal is to identify targets more ...

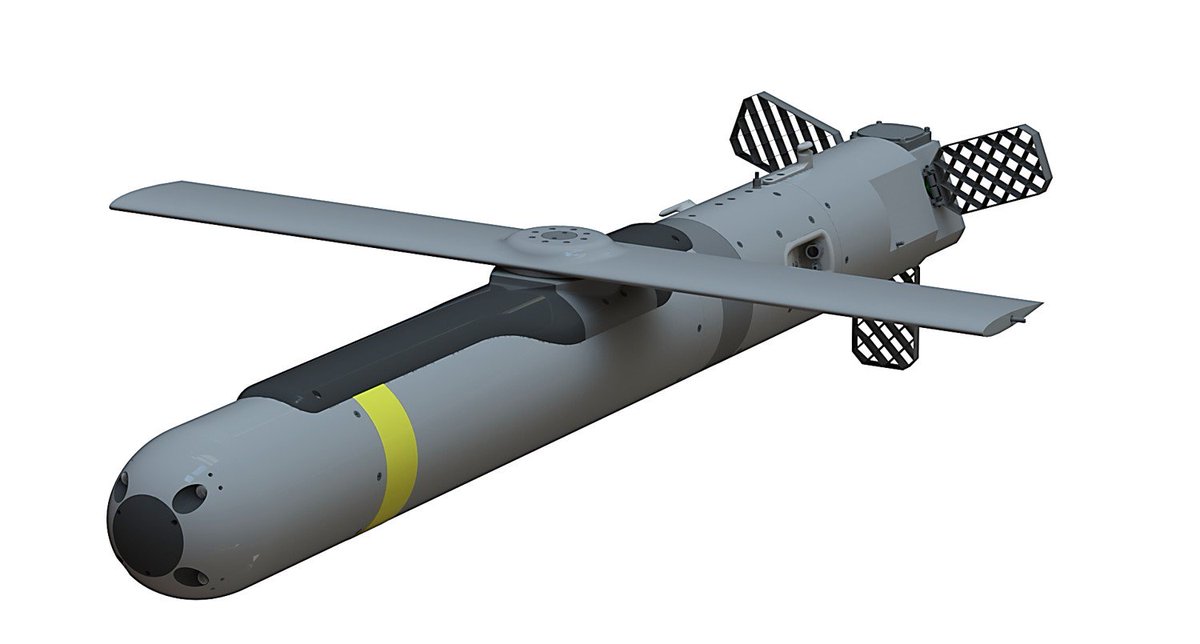

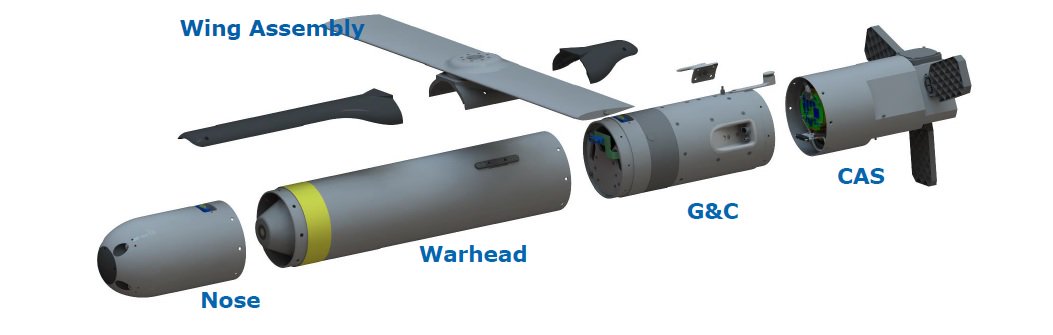

HUNTSVILLE, Ala., June 14, 2016 – Dynetics has been awarded an $11.65 million contract to conduct work on its Small Glide Munition (SGM) for US Special Operations Command.

The SGM is an enhanced capability, 60 lb. class, Stand-Off Precision Guided Munition (SOPGM) that can be carried on AC-130 Gunships or Unmanned Aircraft Systems. The contract will support ongoing integration, qualification and test activities.

“Dynetics is proud to work with SOCOM to rapidly provide an enhanced precision guided munition to our warfighters,” said David King, Dynetics CEO. “This contract marks a significant milestone for Dynetics in development of the SGM and builds on our previous munitions and aerospace systems work.”

Developed with company internal research and development resources, the SGM features a modular design allowing multiple common variants and considerable design flexibility. By mounting the seeker nose section, tail kit and wing assembly directly to the warhead case, the SGM allows different seekers, warheads and other subsystems to be readily incorporated.

The SGM is integrated into a Common Launch Tube and is compatible with the Battle Management System. The baseline SGM design incorporates a 36-lb. blast-fragmentation warhead that can be detonated either on impact or using a variable height of burst sensor. The munition offers an all-azimuth launch capability, while its deployable wing provides significant stand-off range resulting in a large weapon footprint and a corresponding increase in armed over-watch area.

The munition includes a Selective Availability Anti-Spoofing Module GPS receiver, a BAE Systems Distributed Aperture Semi-Active Laser Seeker (DASALS) adapted from the WGU-59/B Advanced Precision Kill Weapon System for terminal guidance, and other advanced features. It also uses lattice control fins for aerodynamic stability and control, similar to Dynetics-developed designs used on the GBU-43/B Massive Ordnance Air Blast and the GBU-57A/B Massive Ordnance Penetrator.

Dynetics initiated development of the Small Glide Munition in 2013 in conjunction with a Collaborative Research and Development Agreement with the USSOCOM Program Executive Office – Fixed Wing. Multiple SGM flight demonstrations against both fixed and moving targets were successfully conducted under the agreement in 2014.Additional flight tests performed earlier this year demonstrated expanded system capabilities.

LONDON—The Royal Netherlands Air Force (RNLAF) has redeployed its two F-35A Joint Strike Fighters back to the U.S. after the international debut of the aircraft at the air force’s Open Dagen air show.

Both aircraft—AN-1 and AN-2—took part in a dramatic air power demonstration as part of the show at Leeuwarden AB on June 10-11.

That ended a three-week deployment that also included noise perception trials at the two airbases—Leeuwarden and Volkel—that will go on to house Dutch F-35s from 2019 onward. The aircraft also performed a series of trials to see if they are compatible with Dutch hardened aircraft shelters from which the jets will eventually be operated.

Tests showed there were no issues with exhaust emissions inside the shelter or noise vibrations that could potentially damage the aircraft. The RNLAF has also been testing the F-35’s Autonomic Logistics Information System, the first time it has been used to support an overseas deployment.

Data collected as part of the noise trials show that people living near the airbases found little difference in the noise levels generated by the F-35 and F-16, based on standard training loadouts. The RNLAF performed a series of 28 passes, 14 with the F-35 and 14 with the F-16. Seven passes were made in the morning and seven in the evening, with and without reheat. Residents were then asked to answer a series of online questions about how they perceived the noise.

The F-35 was initially due to be on static display at the air show. But a push was made to get the fighters into the demonstration, which also included RNLAF F-16s, C-130s, and battlefield helicopters. The show was attended by 280,000 people over two days.

During the visit, the F-35s performed 20 local sorties that generated 32 flying hours. Among these flights was a sightseeing tour of major cities that allowed Dutch citizens to see the aircraft.

The two aircraft departed the Netherlands for Edwards AFB, California, on June 14. They were supported by the RNLAF’s two Douglas KDC-10 aerial refueling aircraft, reversing the route they transited to Europe, flying again via Patuxent River, Maryland.

As part of the visit, the Netherlands government confirmed the financing of a new engine maintenance facility at the RNLAF’s Logistics Center at Woensdrecht. The €88 million ($99 million) price tag will be funded in part by the Dutch defense ministry (50%) and the Netherlands department for economic affairs (25%). The remainder will be funded by the Province of Noord Brabant, the regional government for the Woensdrecht site.

Economic Minister Henk Kamp said the new facility would generate “at least 3,400 man-years of work and around $800 million in revenues” during the life of the program. Maintenance of the first F-135 engine is expected from 2019. Engine maintenance for Italian aircraft will also be carried out there.

The Netherlands currently has four pilots and 27 maintainers, and the number is set to grow substantially over the next three years as the country prepares for 37 aircraft to be based at Leeuwarden from 2019 and then at Volkel from 2021. Of the 37, 29 will be assembled at the European Final Assembly and Check-Out facility in Cameri, Italy.

Once back at Edwards, the two aircraft will continue to support the joint Operational Test & Evaluation program.

Air Force eyeing advanced engine prototype awards this summerEAST HARTFORD, Connecticut—As Pratt & Whitney nears completion of the extensive F135 system development and demonstration (SDD) engine program for the F-35 Joint Strike Fighter, the company is revealing new details of a proposed upgrade plan that could cut fuel burn by as much as 7% on aircraft entering service by the early 2020s.

The upgrade package builds on a fuel burn reduction technology effort driven by the U.S. Navy and an improved compressor developed by Pratt. Initial test results have been positive and are “building a lot of confidence,” that the combination could be introduced as a relatively straightforward “drop-in” upgrade package, says Jimmy Kenyon, senior director of advanced programs & technology at Pratt & Whitney.

However, Pratt stresses the potential upgrade, which would offer extended range and engine life to all variants, will have to be sold to the program before it becomes a reality. “This is not part of the JSF program and not part of the F-35 program. It is a Navy technology demonstration,” Kenyon says. “But right now we are talking to the Joint Program Office, the services and the partners and we are looking at how we would take that technology and transition it into some sort of modernization program that would follow on from SDD. So there’s a long way to go.”

The fuel burn reduction program, initially demonstrated on the modified F135 test engine XTE68/LF beginning in 2013, “has made a lot of progress,” Kenyon says. “The Navy is trying to demonstrate on the test stand a 5% improvement in fuel burn, and when we transition it to the final product there are some other things [with the compressor and turbine] we can do to integrate it into the aircraft that will give you somewhere between 5 and 7% projected fuel burn improvement.”

Working with the Navy, Pratt is taking the turbine cooling technology tested on XTE68/LF “and maturing that design. Instead of pushing the temperature we are buying margin and that’s allowing us to improve the efficiency of that part of the cycle,” Kenyon adds.

The improved design is focused on changes to the aerodynamics of the six integrated bladed rotors (IBRs) that form the high-pressure compressor module, and “takes advantage of the advances in aero design capability that have happened since the start of the F135 program,” he says. The revised configuration was rig tested at AneCom AeroTest’s facility in Wildau, Germany, in 2015. “We got the performance we expected and which we need out of that compressor to enable the overall engine improvement. So that becomes a big risk reduction for the program and that compressor design now is going into the engine demonstrator,” says Kenyon, who adds the integrated test is expected to take place early in 2017.

The Navy, meanwhile, has “put hard constraints” on the extent of the changes with a view to simplifying eventual integration of the upgrades into the existing engine, Kenyon says. “We can’t mess with the diameter because it has to be retrofit-able and variant common. So whether it is increasing thrust, or fuel burn reduction, or if the Marine Corps needs additional powered lift [for the F135-600 powered F-35B short take-off and vertical landing variant] this gives you that capability.” Maintaining commonality with the existing footprint of today’s turbine and compressor sections “allows you to really improve the cost of cutting this into production without any major changes to the rest of engine. It reduces disruption, which is a big deal, and also allows you to do this at the first depot interval.”

The concept is designed for “downward compatibility,” F135 vice president Mark Buongiorno says. “By the time it cuts into production, if there are, say, 1,000 aircraft, then you get the opportunity to bring those 1,000 aircraft up to that current standard. That’s a significant number and it is therefore important to keep the support of the international partners, some of which will have majority of their aircraft delivered by then. That’s how the program will really continue to progress.”

Although initial runs of the combined engine upgrade package will begin as a technology demonstrator next year, Pratt remains realistic about the timeline for potential introduction. “You still have to qualify it on the airplane and so it becomes an issue of timing,” Kenyon says. “The sooner you start it the sooner it becomes available. As you look at opportunities to get that started you are probably looking at early to mid-2020s.”

In the nearer term, Pratt is positioning to improve the performance of the first stage of the F135 three-stage fan through a production change. The company is changing over to a new linear friction-stir weld manufacturing process that will see the current hollow design replaced with a solid blade. “It’s a more efficient design and thinner,” Buongiorno says. The newly installed machine, which is one of the largest of its type in the world, is undergoing commissioning in Pratt’s Compressor System Module Center in Middletown, Connecticut, and more than doubles Pratt’s capacity to do friction welding. After initial use for attaching blades onto the hub of the F135, the device will also be used for welding components of the commercial geared turbofan family.

The change will be cut into production early in 2017. “We are completing validation on the last two test engines today.,” Buongiorno says. “We are actually working to try and accelerate the incorporation as much as we can because it is not only a performance improvement but it is also a significant cost reduction. So we are keen to beat our schedule.”

Pratt has now delivered around 280 F135s and is continuing to accelerate assembly, having completed negotiations for the next production Lots 9 and 10 at end of 2015. Lot 9 already has been awarded and Lot 10, covering 103 engines, is expected to be awarded “imminently,” Buongiorno says. Talks over the following production lots 11 and 12, covering an estimated 130 and 170 engines, respectively, have begun.

HARTFORD, CT -- The Air Force is in the final stages of negotiations with engine-makers Pratt & Whitney and General Electric for a prototype program meant to mature advanced technologies that could be used to field higher-performing and more fuel-efficient engines and upgrades for key Air Force platforms.

The companies have been developing and maturing technologies through the service's Advanced Engine Technology Demonstration program since 2011 and are on pace to conduct hardware demonstrations early next year. At the same time, the Air Force is preparing to launch the next phase of work, the Advanced Engine Transition Program, which will support the two companies as they develop a full prototype engine.

Jimmy Kenyon, Pratt's senior director of advanced programs and technology, told Inside the Air Force this week the service expects to award contracts for AETP this summer and is eyeing a demonstration in the early 2020s.

"We're looking at ways we can try to accelerate that some if we can," Kenyon told ITAF in a June 7 interview at the company's facility in Hartford, CT. "We'd really like to do that if we can but 2020 is probably a good target."

The company flew reporters to Hartford for a tour of its military and commercial engine production facilities.

Although AETD and now AETP are geared toward developing capabilities that could be incorporated on a number of platforms -- whether they be future fighter aircraft or follow-ons to the legacy fleet -- both companies have been designing their hardware enhancements and prototype engines to fit an F-35.

Kenyon said the company's work is focused on an F-35 application, but noted that Pratt is continuing to look at how that might have implications for other platforms. The company, which makes the engines for the Air Force's top three priority programs -- F-35, KC-46 tanker and now the B-21 bomber -- is in a good position to be exploring those other applications, Kenyon said, particularly as the F-35 programs looks to incorporate and compete new capabilities.

He noted that even though AETD and AETP are not billed as F135 follow-on engine programs, the exercise keeps the company "very mindful" of future competition on the program.

"Look, we feel competition every day. Even AETD in its own right keeps us mindful of our position with the F135," Kenyon said. "It's a way to keep us honest on the products that we have. Looking into the future, obviously if the DOD decides that there's a business case that makes sense there and they put it out there, that's what they're going to do. In the future, the door is always open."

The F-35 program does not currently have a requirement for enhanced engine capabilities; however, the company is working with the Navy through its Fuel Burn Reduction program to mature technologies that could be fielded as an upgrade down the road. Kenyon said the company is in discussion with the F-35 joint program office about how to incorporate those upgrades into its follow-on modernization program.

Where the Navy's program would address what Kenyon called "low-hanging fruit" in developing a near-term upgrade plan, AETD and AETP could have longer-term application.

"Looking beyond that, we are looking at ways we can use AETD technologies and insert them into the F135," Kenyon said. "And then of course because we are developing that engine for future applications, it could become a longer-term upgrade as well. So really what we're doing here is we're laying out an option space."

He continued: "It really becomes a continuous upgrade path for the F-35 that's going to keep that airplane flying ahead of its peers well into the future."

http://www.ga-asi.com/predator-b-achiev ... ight-hoursAdditionally, GA-ASI announced that its Predator/Gray Eagle®-series aircraft family set a company record and historic industry feat in 2014: over 500,000 flight hours flown, which is the equivalent of flying 1,370 hours around-the-clock every day.

"GA-ASI works diligently to deliver solutions to meet our customers' requirements and these two achievements wouldn't be possible without the dedication and commitment of our employees," said Frank W. Pace, president, Aircraft Systems, GA-ASI. "These records are a testament to the reliability and durability, as well as the remarkable operational flexibility, of GA-ASI's RPA family."

Predator B achieved this record on February 20 after flying 78,606 sorties. Its first flight occurred at GA-ASI's Gray Butte Flight Operations Facility in Palmdale, Calif. on February 2, 2001. Predator B flight hours now account for approximately one-third of GA-ASI's 3.2 million total flight hours and are increasing at an average rate of over 22,000 hours a month.

Predator B aircraft are currently logging over 700 hours a day supporting the U.S. Air Force, U.S. Department of Homeland Security, NASA, the Italian Air Force, the Royal Air Force, the French Air Force, and other customers. Missions include direct support to warfighters in world hot spots; assisting border agents in monitoring the nation's borders; aiding first responders in the wake of natural disasters; and supporting scientists in performing Earth science missions. GA-ASI has delivered more than 230 Predator B aircraft to date and is currently building three aircraft per month, with the capacity to more than double production if needed.

GA-ASI RPA flight hours continue to increase exponentially each year. The aircraft family logged one million flight hours between 1994 and 2010. It later accrued an additional two million flight hours between 2010 and 2014, bringing the total to over three million hours flown.

Boeing partnered with SAAB for many reasons. Some were:One aspect that did impress me is their tie up with Boeing on the T-X clean sheet design..with all its experience in aviation, Boeing execs are on record as stating that Saab brought in some very niche design capabilities..

Everyone's marketing. No one really stopped after the Rafale was declared the winner. SAAB has a way of offering pie in the sky ideas knowing full well that it may take decades to implement. I had pointed out their GaN EW " First in the WORLD" claim way back, when the timelines they actually put " GaN in EW" would put them at best third and at worst among their competition. But the marketing folks lapped it up and went with it anywaySaab is pushing hard, with some very visible marketing, for both the Gripen, consultancy on Tejas Mk1A, possibly the Mk2 and a JV on the AMCA as well..

Perhaps the reporter should have asked as to why the "BEST AESA" technology isn't going into their own Gripen E/F's, or those being sold to Brazil. It takes a long time to design, develop, integrate, Test and finally operationalize a radar and its associated mission systems. Case in point, the current GaAs AESA they are getting won't go into a fully operational (all originally advertised capability) Gripen NG till 2026. The GaN AESA is something for the late 2020's and early 2030's and I wouldnt be surprised if pretty much everyone else in their competitors had that at or before then. Thats the same stunt they tried pulling with the EW suite.Saab has offered to transfer its gallium nitride (GaN) AESA radar technology to India.“Yes, we are in talks with HAL,” says Jan Widerstrom, chairman of Saab India. “We have the latest avionics, best active electronically scanned array radar and technology in the Gripen which we would be happy to share with HAL for its Tejas program.” Widerstrom says GaN AESA radars are 70% more effective than older AESA radar technology.

SAAB has the ability to make sensors in house. Their best course of action given the way their company is setup is to be agile so that they can source the best components from the various suppliers for those. For years their radar system was procuring RF components from Cree, because the volumes meant a very good price. These were ITAR free but some were government approved as well. However with GaAs and GaN Europe is going towards a shared foundry system where eventually pretty much all are going to source from a common pool made up of collective OEM's and universities. This is different from the US where the big two have the capability to make many RF components in house and won't give that up since they cross over to commercial. Raytheon is still healthy compared to a CREE or a QORVO and the will stay that way because they have huge business in military ( AMDR quadrupled the S band GaN component demand when it was awarded). Cree and Qorvo are obviously the giants but Raytheon can make very precise investments years out since it also makes the sensors. SAAB is more like a Lockheed in that it looks to source from the competitive marketplace and focus on a few niche areas of radars. In case of a Lockheed, this has meant that they have pretty much beaten everyone else in supplying long range GaN surveillance radars to export customers. SAAB has the potential of something similar but that makes them different, not necessarily better since you can at best keep pace with the industry rather than leading it as you would have had you maintained the capability to pull ahead and deliver products ahead of the rest of the base.Maybe like imported engine from US, they're also importing from somewhere and just want to pass screwdriver tech to us?

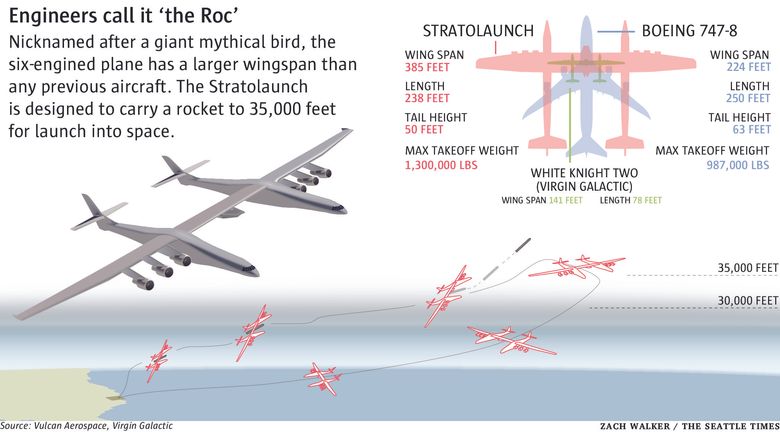

MOJAVE, Calif. — In the high Mojave Desert, the airframe of Paul Allen’s giant, mysterious plane for carrying rockets into space is approaching completion.

It has twin fuselages, 95 feet apart, that are joined across the top by a massive wing, 385 feet from tip to tip — longer than a football field including the end zones.

With a larger wingspan than any aircraft ever built, the six-engined plane — officially called Stratolaunch — has been nicknamed the Roc, after a mythical Middle Eastern bird so big it could carry an elephant in its claws.

Ahead of a major space- industry conference that starts Tuesday in Seattle, Allen’s Vulcan Aerospace last week opened up the secretive assembly plant to a small group of journalists, among other things letting them walk across that massive wing.

The visit suggests that the challenge for Allen’s ambitious project is not whether his plane will fly, but whether his business plan will.

Vulcan’s concept is that this airplane will carry a rocket weighing up to 275 tons slung beneath the central part of the wing — between the two fuselages — and release it at 35,000 feet. The rocket will then launch into space and deliver satellites into orbit.

Unlike today’s massive Atlas and Delta rockets that launch vertically from Earth, the Roc will be able to land, load up and take off again, making space access easier and cheaper. It’s supposed to be more like a routine airport operation than a big Cape Canaveral-style deal.

“When such access to space is routine, innovation will accelerate in ways beyond what we can currently imagine,” Allen said in an emailed statement.

Yet this first close-up look at the great beast elicited not so much a wow response, more a “what the heck?” The plane is awesomely big but also tremendously odd-looking.

Mythic hybrid beast

Strange enough is the basic twin-fuselage, single-wing concept, which gives it the overall look of a pair of insects conjoined at the wing and enlarged to the size of a dinosaur.

Stranger still is the shape of the fuselages, each individually looking like a mythical hybrid beast that morphs from boxy at one end to sleek at the other.

This is the fanciful work of Scaled Composites, the innovative experimental aircraft firm founded by Burt Rutan that has designed and built the airplane and will fly it for Allen’s Vulcan Aerospace.

Any jet airliner you’ve ever flown in has a round fuselage, eschewing corners that could become points of excess pressure. But because the Roc’s aft fuselages are largely empty and unpressurized, the engineers of Scaled Composites went with a simpler-to-build boxy body at the back, rectangular in cross-section.

In the middle of the airplane, its body thickens considerably where it’s topped by the wing, to create clearance for the rocket slung under the wing’s center span.

The forward end of each fuselage is round, because it’s pressurized, and a long drooping neck tapers to a Boeing 747 cockpit, so that it resembles a dinosaur dipping to feed.

The three-person crew — pilot, co-pilot and flight engineer — will sit in a cockpit in the right-hand fuselage, maneuvering the plane from far to the right of the centerline.

The left-hand fuselage has what looks from outside like a cockpit with windows, but it’s empty and unpressurized.

Impressive. Power of high excess available thrust.brar_w wrote:Not bad for something that hasn't yet been cleared for a full 9G display (that comes in 2017)..

Singha ji, USAF has turned its back on UAVs and UCAVs(probably due to the fighter pilot cabal in control). They will pay extremely heavy in future for this folly.Singha wrote:https://www.bellingcat.com/news/2016/06/07/9547/

predators due to be retired in 2018 and reapers are suffering high accident rates.

darshhan wrote:Singha ji, USAF has turned its back on UAVs and UCAVs(probably due to the fighter pilot cabal in control). They will pay extremely heavy in future for this folly.Singha wrote:https://www.bellingcat.com/news/2016/06/07/9547/

predators due to be retired in 2018 and reapers are suffering high accident rates.

brar_w wrote:First Israeli F-35 ADIR rolled out. The first two aircraft will be in Israel by the year end.

Israel's delivery and squadron formation plans are :The Israeli Air Force’s chief of staff has recommended the purchase of an additional 17 F-35 Joint Strike Fighter aircraft, but that decision is pending authorisation from the Israeli government.

Wednesday marked the roll-out of the first Lockheed Martin F-35I Adir, a slightly modified F-35A which will be delivered to Israel’s Nevatim Air Base in December. The U.S. has approved the sale of up to 75 F-35s to Israel and the country has signed contracts for 33 F-35s, the last of which will arrive around 2021, Israeli air force chief of staff Brigadier Gen. Tal Kelman told reporters Tuesday.

Israel has not made a decision on whether it will purchase the additional 17 F-35A-model fighters or when they would be delivered, Kelman says.

“Once we have a decision, we’ll know the timeline,” he says.

While Israel is committed to its order of A variant fighters, its air force is also mulling over a future purchase of the short takeoff and vertical landing (STOVL) F-35B. Israel would start purchasing F-35Bs if the country’s order exceeded 50 aircraft, Kelman says.

The F-35B's STOVL capability could offer significant advantages during an attack on an air base, Kelman says. But he also noted the aircraft’s drawbacks, including its smaller payload and fuel capacity than the conventional F-35A.

Kelman also reasons that regional conflicts would push Israel to complete aircraft maintenance within the country.

“Israel is in the middle of the Middle East and we’re in a daily conflict,” he says. “That is why we don’t want aircraft to leave, we cannot afford having a fighter aircraft go for three months [for] maintenance somewhere.”

While Israel will be able to complete normal aircraft maintenance, heavy maintenance would require significant investment and infrastructure, F-35 programme executive Lt Gen Christopher Bogdan says Wednesday. The US and Israel are forging tailored maintenance solution for Israel, but it won’t happen overnight, Bogdan says.

“There’s some policy issues in the US that we have to work on, there’s some investment by the Israeli government,” he said. “The good news is, when you deliver a new plane like this, you’re not going to need heavy maintenance for quite a long time so there is time to work the policy, infrastructure, tooling and training side to get Israel where they want to be.”

Israel’s push to complete maintenance at home would likely set them apart from other F-35 operators, who could leverage economies of scale with programme's larger, global maintenance infrastructure.

“Israel would like to be able to tap into that economy of scale, but their geo-political situation is such that they may have to do things on their own,” Bogdan says.

IAF Chief of Air Staff: "We want to reach 75 jets"

The Minister of Defense, Avigdor Lieberman, who will lead the Israeli delegation to the rollout ceremony, said that Israel's intention is to equip itself with at least 17 additional F-35 jets that will join the 33 jets whose purchase has already been agreed upon. In the last few months, the Chief of the General Staff, Lt. Gen. Gadi Eizenkot approved the IAF's recommendation to raise the number of Israeli F-35 jets to 50.

"Every opinion I have heard says that this is the best jet in existence today, and we will do what it takes to buy the additional jets", said Lieberman. "Advancing toward a new deal depends of course on the American aid deal which is being discussed currently, but my stance is clearly in favor of purchasing the jets".

The Head of the IAF Chief of Air Staff, Brig. Gen. Tal Kelman, who will also participate in the rollout ceremony today, sees the first 50 jets as an intermediate station. "We want to reach 75 jets", said Brig. Gen. Kelman. "The Israeli F-35 is the first fifth generation fighter to arrive in the Middle East, and it will allow us to open a significant gap in our abilities when facing all of the elements in the area".

According to the Chief of Air Staff, the IAF is already examining the F-35B model equipped with the ability to take off from very short runways and land vertically. "We want the first 50 jets to be A models, but beyond this, we are examining the options. The F-35B may be limited relatively to the A model regarding the amount of munitions it can carry, but has other advantages that may aid us in different scenarios".

Navy engineers are working to bring new aircraft sensors and new weapons into the Naval Integrated Fire Control-Counter Air (NIFC-CA) architecture, with near-term goals of bringing in the F-35’s radio frequency (RF) sensor and the anti-surface variant of the Standard Missile-6.

In a January test, the Navy proved that the new SM-6 Block I anti-surface missile worked, but it also proved that NIFC-CA – which, as its name implies, was engineered to go after fast-moving air threats – could be adjusted to counter surface threats too.

Whereas a normal NIFC-CA anti-air engagement might use an E-2D Advanced Hawkeye as the sensor that finds a target and then use the Cooperative Engagement Capability (CEC) as the link to bring targeting data to the ship that ultimately fires a weapon, the anti-surface technology demonstration required some modifications. A different sensor was needed to identify surface targets, and that sensor could not use CEC, meaning the whole engagement relied instead on Link-16, Anant Patel, major program manager for future combat systems in the Program Executive Office for Integrated Warfare Systems, told USNI News in an interview this month.

Patel did not name the sensor used in the demonstration, but the Navy’s P-8A Poseidon, which is equipped with Link-16, or eventually the unmanned MQ-4C Triton would be ideally suited for the job. Patel said NIFC-CA is sensor-agnostic, as long as the sensor meets quality of service standards. But finding weapons that can hit large but slow-moving targets has its challenges.

“When things go slower, it’s easier” to track them, he said.

“But it has its own complexity also. Some of our weapons are not designed to look for slow targets, so we have to do some analysis and make sure we capture that. Also, if you look at SM-6, it’s more an anti-air weapon, so the capability’s designed to counter fast-moving targets, and then to go against this slow-moving target we had to make sure we can meet that requirement.”

Some minor modifications were made to the Aegis Combat System Baseline 9 to accept the data from the new sensor, but Patel said the culmination of this work – a test in January at the Pacific Missile Range Facility in Hawaii – was a successful hit against a surface target, the decommissioned frigate Reuben James (FFG-57). This success is an early step in fielding a bigger All Domain Offensive Surface Warfare Capability.Another challenge in bringing new weapons into NIFC-CA is that now Naval Sea Systems Command (NAVSEA) and PEO IWS will have to coordinate with Naval Air Systems Command (NAVAIR) and its PEO for Unmanned Aviation and Strike Weapons – NAVSEA owns NIFC-CA and SM-6 but NAVAIR owns the rest of the anti-surface weapons in the inventory.

Patel said NAVSEA and NAVAIR have been in talks for about two months on how to work together.

“From our perspective, they just have the aircraft but we have the entire combat systems, Aegis and SSDS (Ship Self-Defense System), so how do we integrate all that into overall Navy?” he said.

“And then you look at what threat sets you’re going after, they have different requirements and we have separate requirements, so basically understanding each other, what are the requirements, what the capabilities are, where are we today, what are our plans for the future, and then how do we consolidate?”

Essentially, NAVAIR has its own kill chain for employing anti-surface weapons and NAVSEA has its own kill chain for employing anti-air weapons, and the two are trying to merge into a single kill web that shares common sensors, links and weapons.

Patel said that by this fall the two organizations should have a path forward for how to collaborate in engineering, testing and fielding this kill web idea. As new weapons are developed in the future, it should be easier to design them with this collaborative kill web in mind.

Patel said the Navy is also expanding NIFC-CA by introducing more sensors, specifically the F-35. NIFC-CA today primarily relies on the E-2D, which are limited in number. The F-35 will be fielded in great numbers by countries around the world, so the Navy is eager to prove out the NIFC-CA/F-35 combo.

The Navy will conduct a live-fire test in September at White Sands Missile Range in New Mexico, where an F-35 will detect an over-the-horizon threat with its RF sensor and send data back to the USS Desert Ship (LLS-1) land-based ship simulator, which will then launch an SM-6 to intercept the threat.

“It’s no different than E-2D,” Patel said – except that the sensor will be new to NIFC-CA, as will the Mid Air Data Link (MADL) that was developed for F-35s to communicate with one another. The test will assess the Navy’s ability to take unrelated technologies and successfully close the fire control loop.

Patel added that the F-35 brings significant capability to the fleet, but his office is only funded to look at the RF sensor for now. Many of its other sensors could be integrated into NIFC-CA if additional funds were appropriated.

To compare weights of helmets. The original JHMCS I was a 4.5+ pound setup. The JHMCS II is a 4.3 pound system, while the Gen III HMD for the F-35 weighs 5.2 pounds. The re-designed, lightweight helmet weighs in between 4.6-4.8 pounds so is fairly close to the JHMCS I which is the most widely used HMS between the USAF and USN (JHMCS II hasn’t yet been adopted by a US customer, only Saudi’s).There are three primary solutions, he says. The first is to add a “heavy/light” switch to the seat that will delay deployment of the main parachute for lightweight pilots. “We plan to begin modifying seats by the end of the year,” Babione says.

The second fix is to reduce the weight of the Gen 3 helmet-mounted display, developed by Rockwell Collins ESA Vision Systems. The third is to add a fabric mesh between the parachute risers to capture the pilot’s head during ejection

In 2016, Russian space officials announced plans to develop a smaller version of the nation's venerable Proton launch vehicle. The head of Roskosmos Igor Komarov, speaking to the radio station Ekho Moskvy on June 18 said that the Proton-Light variant would be narrowly aimed at particular demands of the commercial market. According to Komarov, an extra variant would make the Proton family more effective and reduce per-kilogram cost of payload delivered into orbit.

Komarov stressed that the Proton would remain in operation for at least seven or nine years, before being replaced with the Angara family.

On June 23, the head of GKNPTs Khrunichev Andrei Kalinovsky announced that the company had been preparing a new addition to the Proton family for a different type of commercial spacecraft, allowing various Proton variants to have their own individual price offers on the market. Kalinovsky did not provide technical details on the new Proton variant, but mentioned that it would not be a drastically new vehicle.

Around the same time, various industry sources revealed the most likely architecture of the Proton-Light rocket. The key change included the removal of the second stage from the standard Proton-M rocket. Instead, the traditional third stage of the Proton-M would be "stretched" to accommodate more propellant and used as the second stage on the Proton-Light. According to some reports, the propulsion system on the second stage could be modified to re-start its engine and boost its payload from an initial parking orbit to a geostationary transfer orbit, GTO. Some estimates showed that under such a scenario, the vehicle could deliver up to five tons of cargo to the GTO after launch from Baikonur.

Another configuration could use a Briz-M space tug as the third stage of the rocket.

In its new configuration, Proton-Light could fill the gap in the payload range left by the Zenit rocket, which itself fell victim to Russia's conflict with Ukraine. The new Proton variant would also be well positioned on the international market, which saw more competition with the arrival of the American Falcon-9 rocket.

However given the extended length of time required for even less radical upgrades of Proton and the official Russian strategy to phase out the vehicle in favor of Angara-5, it is unclear whether it would be possible to justify the Proton-Light development effort. A number of previous proposals to change the shape and size of the Proton-M rocket were deemed too expensive more than a decade earlier in the rocket's operational career.

Major dilemma :Japan’s defense ministry is requesting information for its next fighter program, taking an early step toward an acquisition that will shape the country’s air force in the middle of the century and perhaps result in a domestic development effort.

The ministry is seeking information on three alternatives: creating a new fighter type, modifying an existing one or importing. The aim is to replace the Mitsubishi Heavy Industries Ltd. (MHI) F-2.

There are strong reasons to suspect that the ministry would only be satisfied with a new type, since no fighter now in production comes close to concept designs of the past few years that likely show what it really wants: a large, twin-engine aircraft with long endurance and internal carriage of six big air-to-air missiles.

That does not necessarily mean foreign companies will be wasting their time by responding, however. Even a domestic program led by MHI and engine builder IHI Corp., if affordable, would benefit from foreign guidance and technology.

For new designs, the ministry’s acquisition, technology and logistics agency has requested information on respondents’ capabilities and latest technology. For upgrades and straight imports, it wants to know about the current aircraft. In seeking the data, it is not using the conventional term “request for information,” but that is clearly what the exercise amounts to. Responses are due by July 5.

Four categories of companies have been invited to respond: those that have built airframes or engines, those that can show they have knowledge of developing and building them, trading companies and consultancies. The first group, manufacturers, most obviously includes MHI and IHI—and maybe such suppliers as Boeing, BAE Systems, Dassault and Saab, if they are not expected to go through trading companies. The second category appears to create an opening for such companies as Israel Aerospace Industries, which have not built fighters of entirely their own design but know a thing or two about the technology.The trading companies have been invited because they are a routine and peculiar element of Japanese defense equipment importation, acting as local intermediaries. In the F-X program that Lockheed Martin secured in 2011 with the F-35 Lightning, for example, the winning bid’s Japanese trading company was Mitsubishi Corp., while Itochu represented Boeing and the F/A-18E/F Super Hornet. Sumitomo Corp. represented Eurofighter and the Typhoon.

The Japanese government is due to decide by the fiscal year beginning April 2018 how to replace the F-2. A new type’s entry into service around 2030 has been expected, so the chosen type will serve well into the second half of the century.

MHI, IHI and other Japanese companies have been working on laying the technical foundation for a domestic type that would closely fit the ministry’s requirements. That or a gross modification of a foreign aircraft would be called the F-3.

The government would have to vastly increase its defense research and development budget to create an all-new F-3. In no year since 1988 has the country spent more than ¥173 billion ($1.64 billion at today’s exchange rates) on military R&D (see chart). Peak annual spending on F-2 development was about ¥100 billion. The F-3’s expected development cost is unknown, but the U.S. spent $30.4 billion on developing the Lockheed Martin F-22, which is quite comparable to concept designs of the F-3 published by the ministry’s Technical Research and Development Institute (TRDI). On the other hand, the F-2, based on—but larger than—the Lockheed Martin F-16, cost only ¥360 billion to develop more than two decades ago.

The F-2 is a strike fighter, but Japan clearly does not want to buy another. TRDI’s concept designs unambiguously emphasize the counterair role. The institute calculates that fighters with long endurance and therefore greater numbers on station would be more useful than those with better flight performance in battle. They would engage targets at great range with internally stowed missiles that, low-resolution drawings suggest, would be ramjet-powered.

TRDI’s concepts also include stealthy airframes.

Among the politically and technically acceptable aircraft that could conceivably be updated or imported unchanged to replace the F-2, the Boeing F-15 has been in Japanese service since the 1980s. It may offer the endurance Japan wants, but it lacks weapon bays and the most demanding stealth features. So does the F/A-18E/F, though limited internal missile capacity in pods has been proposed for both types. The Typhoon, Dassault Rafale and Saab Gripen E/F have similar limitations and probably fall short of Japan’s endurance requirement. The stealthy F-35 has only limited internal weapon stowage and is probably also too short-legged.

No foreign development program has a concrete schedule that would supply Japan with an acceptable aircraft, though the U.S. Navy and Air Force have requirements that may approximately match Tokyo’s targeted timing and performance.

Saudi Arabia weapons

Members of the activist group CodePink hold a rally to protest US weapons sales to Saudi Arabia in Washington DC on Wednesday. Photograph: UPI /

Julian Borger Washington

Thursday 8 September 2016 18.10 BST Last modified on Friday 9 September 2016 00.55 BST

The Obama administration has offered to sell $115bn worth of weapons to Saudi Arabia over its eight years in office, more than any previous US administration, according to a new report.

The surge in sales is in part to reassure the Saudi monarchy of US backing in the wake of last year’s nuclear deal with Tehran, which raised fears in the Gulf that Washington would tilt more towards Tehran in its foreign policy.

The report’s author, William Hartung of the Centre for International Policy, said another factor was a drive by US arms manufacturers to boost sales to compensate declining procurement by the Pentagon. However, the most recent deals – such as the offer to sell more than 150 M1A2 Abrams battle tanks for an estimated $1.15bn – were principally intended to replenish the Saudi arsenal, depleted in the war in Yemen.

“I think that though the Obama administration is not thrilled about the Yemen episode; it feels it can’t stay out of it, because of the need to reassure the Saudis,” Hartung said.

His report found that since taking office in January 2009, the Obama administration has offered to sell $115bn in weapons to Saudi Arabia, half of which are accounted for by deals that are still in the pipeline.

“There are $57bn in sales in formal agreements so far, which is also head and shoulders above other administrations,” Hartung said.

The report comes as concerns about the UK’s arms sales to Saudi Arabia and their implication in potential war crimes in Yemen have split MPs on parliament’s arms control committee.

Arms sales over the eight years of the Obama administration have also included combat aircraft, attack helicopters, bombs, air-to-ground missiles, warships and military training. A division of Northrop Grumman is involved in a $4bn train-and-equip programme for the Saudi Arabian national guard, which has reportedly played a key role in the Yemen intervention.

The latest tank deal has drawn resistance from congressional Democrats, who have called for a freeze on arms sales to Saudi Arabia, because of its bombing of civilian targets in Yemen. UN officials have estimated that airstrikes by the Saudi-led coalition are responsible for most of the 3,000 civilian casualties in the war so far, twice as many as those caused by Houthi insurgents and other forces in the conflict put together.

Ted Lieu, a Democratic congresman from California, took a leading role in a letter by 64 members of Congress calling for the tank deal to be delayed, given the coalition’s campaign’s “deeply troubling impact on civilians”.

“I do not oppose assisting the country of Saudi Arabia, which has been a longstanding ally of the United States,” Lieu told the Guardian in a written statement. “What I do fundamentally oppose is continuing to sell arms to a military coalition that has repeatedly committed war crimes. The Saudi-led coalition has killed children, patients, doctors and newlyweds. A significant number of the killings of civilians by the Saudi coalition were nowhere near military targets. I will continue to do all that I can to see that the United States offers no support to Saudi Arabia’s operations in Yemen. The letter that 64 Members of the House sent last week shows that there is a growing chorus in Congress that shares these concerns.”

Tom Porteous, deputy programme director for Human Rights Watch, said: “As Human Rights Watch has documented in frequent field missions to bombing sites, US weapons are being used in coalition attacks that violate the laws of war and in some cases may constitute war crimes … To continue to sell arms is to fuel the flames and enable further violations.”

'Why do they target us?' Yemeni civilians pay the price of escalating crisis

The US has made appeals to Riyadh to do more to limit civilian casualties, and pointed to Riyadh’s creation of a committee to investigate incidents like the bombing of hospitals as progress in that direction. But the committee has shared information with the UN but not made its findings public. Hartung argued that such messages are least likely to be taken seriously while arms sales are booming.

“I think the US is such a significant supplier of bombs, ammunition, artillery and tanks and playing such an important role in the prosecution of the war in Yemen that there is signficant leverage,” he said. “If the US were to signal that part of that assistance would be frozen or withdrawn if they don’t show they are implementing measures to limit civilian casualties, that would send an effective message. I haven’t seen evidence that they have really made a convincing threat or statement on the consequences for the Saudis if they don’t stop. And any such message would be more powerful if other suppliers like the UK made similar statements.”