Kaveri & Aero-Engine: News & Discussion

Re: Kaveri & Aero-Engine: News & Discussion

^^^Thank you Maitya ji

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/shreedharsingh9/status/19 ... 5560937894

@shreedharsingh9

D1 is only for baseline thrust, material integrity, and accelerated endurance.

In 2026 D2 & D3 Will go into endurance trials for 150 hrs under High altitude condition

D4 and D5 will then undergo qualification tests for 300-500 hours.

@shreedharsingh9

D1 is only for baseline thrust, material integrity, and accelerated endurance.

In 2026 D2 & D3 Will go into endurance trials for 150 hrs under High altitude condition

D4 and D5 will then undergo qualification tests for 300-500 hours.

Re: Kaveri & Aero-Engine: News & Discussion

Kaveri indigenous content to go up from 85% to 90%

GTRE का दावा! कावेरी इंजन में 90% देसी पार्ट्स का इस्तेमाल, तेजस को मिलेगी 'जबरदस्त' ताकत

https://zeenews.india.com/hindi/zee-hin ... ca/2948426

GTRE का दावा! कावेरी इंजन में 90% देसी पार्ट्स का इस्तेमाल, तेजस को मिलेगी 'जबरदस्त' ताकत

https://zeenews.india.com/hindi/zee-hin ... ca/2948426

Re: Kaveri & Aero-Engine: News & Discussion

vera_k, What exactly is the difference between a true FADEC and this early version of Kaveri FADEC?

Other than the manual back up which they said is due to fear of electronic failure.

The early controller acronym is KADECU which stands for Kaveri Digital Engine Control Unit.

They say they have manual back up but talk about manual control linkages etc.

These are components of an Engine control unit which links to the throttle lever.

So this is not a true FADEC which has full authority digital Engine Control.

Link: https://web.archive.org/web/20110220152 ... averi.htmlKaveri engine is controlled by Kaveri full authority digital control unit {KADECU), which has been developed and successfully demonstrated at DRDO's test bed.

So GTRE has been economical with the facts.

They keep repeating over the years that Kaveri has a digital controller which is not a FADEC.

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/Kunal_Biswas707/status/19 ... 8150590473

@Kunal_Biswas707

Found this impression of RTA70 with turbojets & nice snap of Kaveri on IL-76 at Gromov Flight Research Institute in Russia back in 2010-11, it's not too late to have a RTA90 variant with 2 x Kaveri / Kabini, start with military variant for all certification then civil

https://x.com/Kunal_Biswas707/status/19 ... 8111462644

@Kunal_Biswas707

What is more unfortunate for Indian aerospace industry is that they had a transport aircraft engine called KABINI but never went for certification or being pushed for indigenous aircraft program such as NAL NCA or RTA-70 which were was once featured turbo jet engines.

@Kunal_Biswas707

Found this impression of RTA70 with turbojets & nice snap of Kaveri on IL-76 at Gromov Flight Research Institute in Russia back in 2010-11, it's not too late to have a RTA90 variant with 2 x Kaveri / Kabini, start with military variant for all certification then civil

https://x.com/Kunal_Biswas707/status/19 ... 8111462644

@Kunal_Biswas707

What is more unfortunate for Indian aerospace industry is that they had a transport aircraft engine called KABINI but never went for certification or being pushed for indigenous aircraft program such as NAL NCA or RTA-70 which were was once featured turbo jet engines.

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/MeghUpdates/status/1979595196200308867

@MeghUpdates

BIG! India’s Kaveri Engine programme gets a major boost as PTC Industries receives LoTA from CEMILAC–DRDO for indigenous Titanium castings for the Kaveri Derivative Engine (KDE-2).

@MeghUpdates

BIG! India’s Kaveri Engine programme gets a major boost as PTC Industries receives LoTA from CEMILAC–DRDO for indigenous Titanium castings for the Kaveri Derivative Engine (KDE-2).

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/SJha1618/status/197952266 ... EOTGQ&s=19

https://x.com/SJha1618/status/197984757 ... ZLU8g&s=19Very important development:

'PTC Industries also received a Purchase Order for Post-Cast Operations to manufacture Single Crystal ‘Ready-to-Fit’ Turbine Blades for the Kaveri Derivative Engine (KDE-2).'

https://x.com/shreedharsingh9/status/19 ... OX89Q&s=19Second gen SX blade investment casting capability implies mastery of the Bridgman Method preferred by the West ( Russians use LMC). The most popular 2nd gen SX blade alloy is of course CMSX-4. Importantly, that is out of patent.

https://x.com/shreedharsingh9/status/19 ... 5Mjyw&s=19Most likely We are going to use CMSX4 in KDE which is the 2nd generation SX blade. The raw temperature of Cmsx4 is 1080°- 1090°c .

SX blades make more advanced internal cooling (serpentine, impingement, multi-pass ) possible, while DS blades are more restricted.

You can safely drill many tiny film holes, even in critical areas like the suction side or tip because it can handle more holes and stress without cracking.

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/alpha_defense/status/1983487613853188280

@alpha_defense

MIDHANI receives Airworthiness Certification from CEMILAC for indigenous Superalloys, Titanium & Special Steels for advanced aero engines, enabling series production of airworthy components.

@alpha_defense

MIDHANI receives Airworthiness Certification from CEMILAC for indigenous Superalloys, Titanium & Special Steels for advanced aero engines, enabling series production of airworthy components.

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/prasannavishy/status/1984077095237014005 ---> As Delhi closes in on the Safran deal to co-develop a (120 - 140 kN?) engine for AMCA, domestic industry body wants a parallel “Mission Aero Engine” to design and manufacture a homegrown 110 kN core through the private sector. Society of Indian Defence Manufactures says India will need 700+ engines over the next decade for Tejas Mk-1A/Mk-2 and AMCA. A market worth ₹60,000 crore. But over-dependence on foreign partners leaves both defence and civil aviation vulnerable to sanctions. Unlike the proposed AMCA–Safran co-development (which may give India tech access but limited IP ownership), Mission Aero Engine seeks full indigenous control (from turbine materials to hot-section design). Capability gap? India’s Kaveri reached only ~80 kN thrust. So scaling to 110 kN needs deeper mastery in single-crystal blades, high-temperature alloys, and afterburner efficiency which are some of the areas where GTRE still lags. @businessline report

Re: Kaveri & Aero-Engine: News & Discussion

Instead of shooting for a 110KN engine, I think the first priority should be the development of an 85KN Kaveri derivative engine to replace the GE404-IN20 when they come in for replacement. At least 400 of these engines will be needed for the 2 engine replacement cycles of the Tejas Mk1A. GE may not keep its production lines open till that time.

How far is the Kaveri Derivative Engine from this goal? I understand that GTRE is working with Godrej Aerospace and Brahmos and other companies towards enhancing the thrust of the Kaveri engine. Should Safran's or Rolls Royce's help be sought in this development?

How far is the Kaveri Derivative Engine from this goal? I understand that GTRE is working with Godrej Aerospace and Brahmos and other companies towards enhancing the thrust of the Kaveri engine. Should Safran's or Rolls Royce's help be sought in this development?

Re: Kaveri & Aero-Engine: News & Discussion

well both can go in parallel as well, unless money is the constraint,Kakkaji wrote: ↑02 Nov 2025 08:01 Instead of shooting for a 110KN engine, I think the first priority should be the development of an 85KN Kaveri derivative engine to replace the GE404-IN20 when they come in for replacement. At least 400 of these engines will be needed for the 2 engine replacement cycles of the Tejas Mk1A. GE may not keep its production lines open till that time.

if we target 110kN... we may well achieve 90-99kN

Re: Kaveri & Aero-Engine: News & Discussion

I just like Automotive engines, size, dimension specific fuel consumption matter, Al31FP engine dimensions are much bigger, heavier and consumes too much fuel for light or medium Aircraft, you can't fit a Toyota innova 2.7 liter Engine gearbox combo in a Maruti Alto. A truck engine will provide loads of Torque , is huge, heavy, but it cannot be designed to rev fast and high.

So it's not just output it's output with dimensions, weight , fuel consumption, MTBF etc. So it's is better to design 2-3 engines and also devlop High bypass engines for Transport Aircraft.

So it's not just output it's output with dimensions, weight , fuel consumption, MTBF etc. So it's is better to design 2-3 engines and also devlop High bypass engines for Transport Aircraft.

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/DefenceDecode/status/1987057171742532056

@DefenceDecode

RM Rajnath Singh stated that within the next year, India will achieve a significant milestone whereby the engines for all fighter aircraft will be manufactured domestically - by Indian companies and by the skilled hands of the Indian workforce.

@DefenceDecode

RM Rajnath Singh stated that within the next year, India will achieve a significant milestone whereby the engines for all fighter aircraft will be manufactured domestically - by Indian companies and by the skilled hands of the Indian workforce.

Re: Kaveri & Aero-Engine: News & Discussion

I really don't see how this is possible. F404 still has to come from the US. Even if this is just limited to local "assembly",manufactured is quite a strong worduddu wrote: ↑08 Nov 2025 14:29 https://x.com/DefenceDecode/status/1987057171742532056

@DefenceDecode

RM Rajnath Singh stated that within the next year, India will achieve a significant milestone whereby the engines for all fighter aircraft will be manufactured domestically - by Indian companies and by the skilled hands of the Indian workforce.

Even if we take this at face value, technically this doesn't cover choppers, basic, intermediate or advanced trainers. Hopefully we are covered in terms of uav use. The statement is politically well made, to which there could be a lot of caveats and loopholes.

Re: Kaveri & Aero-Engine: News & Discussion

Indian industry should focus on getting Kaveri to spec and creating derivatives of Kaveri for many new use cases.

Re: Kaveri & Aero-Engine: News & Discussion

Fighter jet engine | Battle for a jet engine

https://www.indiatoday.in/magazine/defe ... 2025-11-07

07 Nov 2025

https://www.indiatoday.in/magazine/defe ... 2025-11-07

07 Nov 2025

“One should know what to ask for...unless you ask for it, the original equipment manufacturer will never share something that took decades to develop,” says a scientist.

-

Prem Kumar

- BRF Oldie

- Posts: 4670

- Joined: 31 Mar 2009 00:10

Re: Kaveri & Aero-Engine: News & Discussion

Rajnath Singh channeling his inner-Gadkariuddu wrote: ↑08 Nov 2025 14:29 https://x.com/DefenceDecode/status/1987057171742532056

@DefenceDecode

RM Rajnath Singh stated that within the next year, India will achieve a significant milestone whereby the engines for all fighter aircraft will be manufactured domestically - by Indian companies and by the skilled hands of the Indian workforce.

Re: Kaveri & Aero-Engine: News & Discussion

I wish... within a year ?

I will be indebited if within a year, we choose the direction we are heading down and shortlist our strategic partner.

I will be indebited if within a year, we choose the direction we are heading down and shortlist our strategic partner.

Re: Kaveri & Aero-Engine: News & Discussion

They really need a plan to get Kaveri across the finish line and test it on an Indian testing platform and the end platform to really cross all hurdles. They can do whatever they want with Safran, unless they do this, the Safran deal wont be that effective.

Re: Kaveri & Aero-Engine: News & Discussion

Big- Kaveri Engine पर बड़ी सफलता - Kaveri Engine Big Update

In a critical boost to India's quest for self-reliant aero-engines, the Defence Research and Development Organisation (DRDO) has fully qualified and inducted its Advanced Full Authority Digital Engine Control (A-FADEC) unit into the Kaveri Dry Engine program. This sophisticated digital brain, designed to orchestrate the non-afterburning variant of the indigenous Kaveri turbofan, has amassed nearly 300 hours of in-engine testing alongside over 1,300 cumulative hours on test rigs, including 75 hours at simulated altitudes. The 2024 highlight: groundbreaking flame-out and auto-relight logics tested in Bangalore, ensuring unflinching performance in the harshest skies.

In a critical boost to India's quest for self-reliant aero-engines, the Defence Research and Development Organisation (DRDO) has fully qualified and inducted its Advanced Full Authority Digital Engine Control (A-FADEC) unit into the Kaveri Dry Engine program. This sophisticated digital brain, designed to orchestrate the non-afterburning variant of the indigenous Kaveri turbofan, has amassed nearly 300 hours of in-engine testing alongside over 1,300 cumulative hours on test rigs, including 75 hours at simulated altitudes. The 2024 highlight: groundbreaking flame-out and auto-relight logics tested in Bangalore, ensuring unflinching performance in the harshest skies.

Re: Kaveri & Aero-Engine: News & Discussion

Kaveri (Dry & AB) Next Step

Dry Kaveri delayed due to delay in allotting slot in Russia for testing for its certification testing process. Ghatak project to be delayed by 2 to 3 years. Even Kaveri with Brahmos Afterburner project delayed due to this. Lack of our own flying test bed the reason.

Dry Kaveri delayed due to delay in allotting slot in Russia for testing for its certification testing process. Ghatak project to be delayed by 2 to 3 years. Even Kaveri with Brahmos Afterburner project delayed due to this. Lack of our own flying test bed the reason.

Re: Kaveri & Aero-Engine: News & Discussion

^^ Given serious reorganisation of the order, I dont think we will be Self sufficient or Atmanirbhar in the real sense any time sooner.

We are being given the boot by all and sundry.

We will be made to pay for everything but only of slightly lower end Maal will be sold.

We are being given the boot by all and sundry.

We will be made to pay for everything but only of slightly lower end Maal will be sold.

Re: Kaveri & Aero-Engine: News & Discussion

One of our Il-76 can be converted to flying engine testbed if both the IAF and political leadership decides. DRDO could get it done, even with some support from the Russians. Risk taking ended with Manohar Parrikar.

Re: Kaveri & Aero-Engine: News & Discussion

This is a great video to understand how modern jet engines work, the challenges with turbine blade metallurgy, mechanical strength etc. Great visuals to help understand the crystal structure and thin film coating. Techniques to achieve cooling at temperatures exceeding the melting point of the blade alloy and the need to handle dirt and pollutants. Good cutaway of a modern blade with cooling holes and the ridged structure of the core.

The video shows the process at Rolls Royce.

What happens if you throw sand into a jet engine?

0:00 How a jet engine works

3:18 Why are jet engines so big?

5:17 The Inside of a Jet Engine

8:49 Edge Dislocation

11:11 The First Jet Engine

12:48 Inside the Rolls-Royce Precision Casting Facility

17:07 Nickel Superalloys - Gamma Prime

23:58 Crystal Structure

25:38 Making a Turbine Blade

32:22 Why don’t turbine blades melt?

35:30 Throwing Sand Into a Jet Engine

The video shows the process at Rolls Royce.

What happens if you throw sand into a jet engine?

0:00 How a jet engine works

3:18 Why are jet engines so big?

5:17 The Inside of a Jet Engine

8:49 Edge Dislocation

11:11 The First Jet Engine

12:48 Inside the Rolls-Royce Precision Casting Facility

17:07 Nickel Superalloys - Gamma Prime

23:58 Crystal Structure

25:38 Making a Turbine Blade

32:22 Why don’t turbine blades melt?

35:30 Throwing Sand Into a Jet Engine

Re: Kaveri & Aero-Engine: News & Discussion

FYI, Maitya-ji...as always, please provide inputs

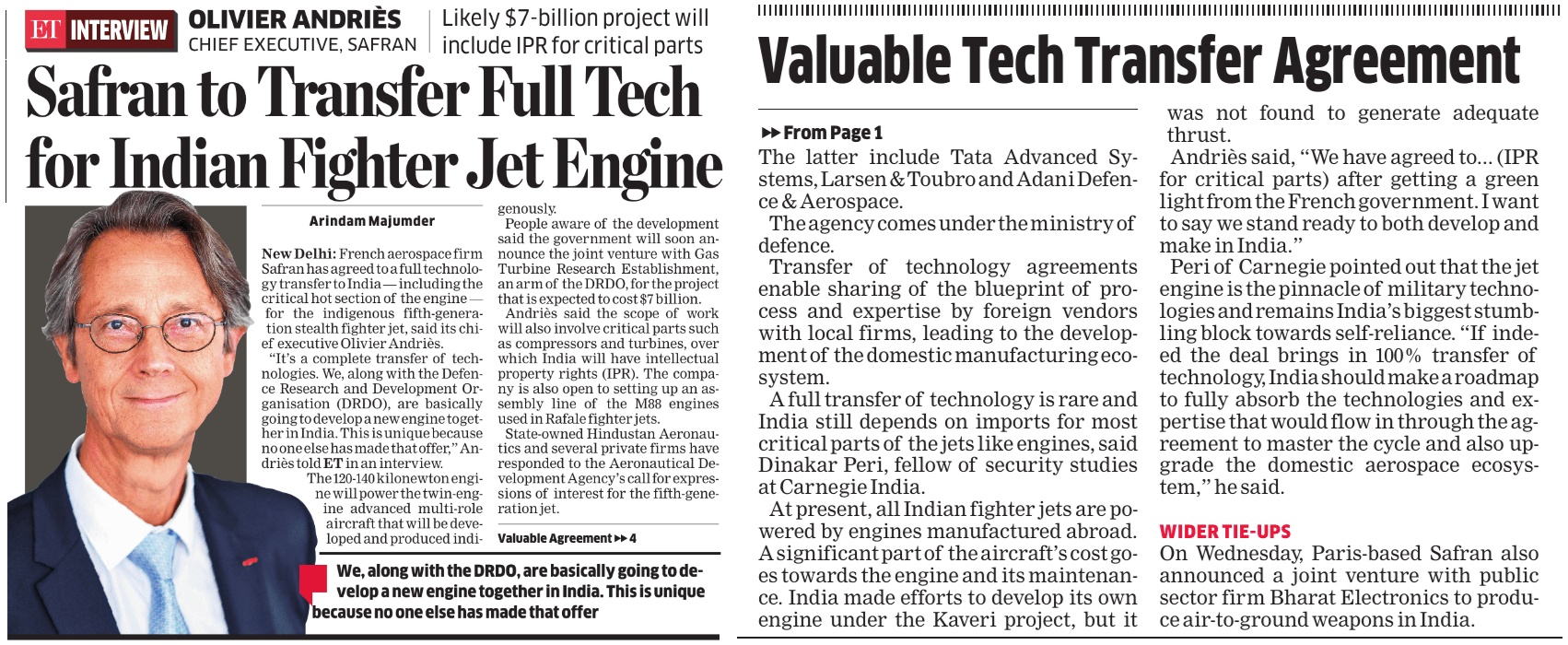

Big boost for India's 5th gen fighter plane project: Safran clears full jet-engine tech transfer, says report

https://www.moneycontrol.com/news/india ... 98459.html

27 Nov 2025

Big boost for India's 5th gen fighter plane project: Safran clears full jet-engine tech transfer, says report

https://www.moneycontrol.com/news/india ... 98459.html

27 Nov 2025

Safran CEO Olivier Andries said that the company will work with the Defence Research and Development Organisation to co-develop the engine in India, calling the scope of the transfer unprecedented.

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/cvkrishnan/status/1993932 ... 24591?s=20 ---> “We along with DRDO are basically going to develop a new engine together in India. The scope of work will also involve critical parts development over which India will have intellectual property rights” - Safran CEO. Think of this as a Brahmos type joint development deal + mfg ToT and design rights for the hot section.

Tweet below is in reply to the above ^^^ tweet

https://x.com/Freak1411/status/1994003264803885156?s=20 ---> I find this a little amusing. They want to transfer the tech for something they don't have and are yet to 'jointly develop'? Tech can only be transferred for something that does exist. If I connect the dots, IMV they won't be sharing their latest tech. A M88 at best!

Tweet below is in reply to the above ^^^ tweet

https://x.com/cvkrishnan/status/1994025 ... 91362?s=20 ---> Many have misunderstood this Joint development deal. The hot section is going to be developed with Safran in lead and the cold sections with GTRE in lead. Scientists and engineers of each are going to be embedded in the teams of the other during development. So technology will be developed together. So there’s no question of “hiding” beyond a point.

========================================================

https://x.com/lakshmishaks/status/19939 ... 65377?s=20 ---> India may get full fighter-jet engine tech transfer from Safran, but “full” often excludes proprietary processes and export controls. A 120–140 kN engine for AMCA could still face IP carve-outs, material tech gaps and long test cycles. Big promise, but proof is in the delivery.

========================================================

https://x.com/prasannavishy/status/1993 ... 77670?s=20 ---> Safran says it is ready for a rare full technology transfer (including IPR for critical parts) for AMCA, India’s indigenous fighter jet engine program in partnership with DRDO. The $7 Billion project will cover hot-section tech, compressors and turbines, and power India’s 5th-gen fighter ambitions. Full ToT on paper doesn’t guarantee mastery. Absorption capacity, domestic supply-chain depth, materials science, and test infrastructure will decide whether this becomes a true engine ecosystem or another licensed assembly line.

Tweet below is in reply to the above ^^^ tweet

https://x.com/cvkrishnan/status/1993895 ... 99104?s=20 ---> Key will be the individual initiative and interest of the scientists and project leaders on our side to absorb the tech. And supplementary investments in our side to absorb the learnt tech beyond DRDO to a research ecosystem of industry academia where further work continues beyond this project. Involve and create redundant research capacities to retain and further propagate the tech.

Tweet below is in reply to the above ^^^ tweet

https://x.com/Freak1411/status/1994003264803885156?s=20 ---> I find this a little amusing. They want to transfer the tech for something they don't have and are yet to 'jointly develop'? Tech can only be transferred for something that does exist. If I connect the dots, IMV they won't be sharing their latest tech. A M88 at best!

Tweet below is in reply to the above ^^^ tweet

https://x.com/cvkrishnan/status/1994025 ... 91362?s=20 ---> Many have misunderstood this Joint development deal. The hot section is going to be developed with Safran in lead and the cold sections with GTRE in lead. Scientists and engineers of each are going to be embedded in the teams of the other during development. So technology will be developed together. So there’s no question of “hiding” beyond a point.

========================================================

https://x.com/lakshmishaks/status/19939 ... 65377?s=20 ---> India may get full fighter-jet engine tech transfer from Safran, but “full” often excludes proprietary processes and export controls. A 120–140 kN engine for AMCA could still face IP carve-outs, material tech gaps and long test cycles. Big promise, but proof is in the delivery.

========================================================

https://x.com/prasannavishy/status/1993 ... 77670?s=20 ---> Safran says it is ready for a rare full technology transfer (including IPR for critical parts) for AMCA, India’s indigenous fighter jet engine program in partnership with DRDO. The $7 Billion project will cover hot-section tech, compressors and turbines, and power India’s 5th-gen fighter ambitions. Full ToT on paper doesn’t guarantee mastery. Absorption capacity, domestic supply-chain depth, materials science, and test infrastructure will decide whether this becomes a true engine ecosystem or another licensed assembly line.

Tweet below is in reply to the above ^^^ tweet

https://x.com/cvkrishnan/status/1993895 ... 99104?s=20 ---> Key will be the individual initiative and interest of the scientists and project leaders on our side to absorb the tech. And supplementary investments in our side to absorb the learnt tech beyond DRDO to a research ecosystem of industry academia where further work continues beyond this project. Involve and create redundant research capacities to retain and further propagate the tech.

Re: Kaveri & Aero-Engine: News & Discussion

Somewhat amusing about transfer of tech by Safran.

Issue could be something more geopolitical.

I don't know how to put it properly. May be completely wrong also.

Rafale orders are over 530.

More orders expected.

France struggling to meet the demand.Of course India thru operation Sindoor gave free publicity.

Dassault can only build 24 planes yearly. It is finding difficulties in fulfilling its obligations to its customers.

They will lose markets otherwise.

India is a reliable partner, great market,lot of talent with engineers etc untapped talent youth etc.

No other country has this opportunity. China not included due to its adversarial problems stealing etc.

So building capacity maintenance etc in India will reduce cost quicker turnover for Rafale customers.

India gets its share taken care of.

---------------------

Russia will be hit severely here.

Russia normally gave more transfers relative to western nations.

Lot of help offered relatively.

I expect more counter offers from Russia to sweeten their deals.

Uncle may be sulking and sanction more on Russia.

Put pressure on India thru various levers etc

If orange monkey becomes mad,he will sanction France also.

The whole geopolitical issue is because of well oiled diplomacy by India.

A huge swing state that everyone wants to have on their side.

-------

Safran may not give the most important tech.

Reminds me of the piece of cloth which covers most important parts leaving rest to imagination.

Issue could be something more geopolitical.

I don't know how to put it properly. May be completely wrong also.

Rafale orders are over 530.

More orders expected.

France struggling to meet the demand.Of course India thru operation Sindoor gave free publicity.

Dassault can only build 24 planes yearly. It is finding difficulties in fulfilling its obligations to its customers.

They will lose markets otherwise.

India is a reliable partner, great market,lot of talent with engineers etc untapped talent youth etc.

No other country has this opportunity. China not included due to its adversarial problems stealing etc.

So building capacity maintenance etc in India will reduce cost quicker turnover for Rafale customers.

India gets its share taken care of.

---------------------

Russia will be hit severely here.

Russia normally gave more transfers relative to western nations.

Lot of help offered relatively.

I expect more counter offers from Russia to sweeten their deals.

Uncle may be sulking and sanction more on Russia.

Put pressure on India thru various levers etc

If orange monkey becomes mad,he will sanction France also.

The whole geopolitical issue is because of well oiled diplomacy by India.

A huge swing state that everyone wants to have on their side.

-------

Safran may not give the most important tech.

Reminds me of the piece of cloth which covers most important parts leaving rest to imagination.

Re: Kaveri & Aero-Engine: News & Discussion

Kaveri will end with UCAV. Spineless, braindead idiots at the helm. The Complete Tejas MK1/MK1A program is now vulnerable. We will again be running to the French for the engines sooner or later when the F-404 is sanctioned. Literally handing over the biggest stick to the Americans to beat us with. What to do with these duffers at the helm? Now the Americans will utilize it. The Sanctions will happen. Tejas program will be grounded.

"The decision..." India's Defence Secretary Rajesh Kumar Singh gives big update on Kaveri Jet Engine

"The decision..." India's Defence Secretary Rajesh Kumar Singh gives big update on Kaveri Jet Engine

"The decision..." India's Defence Secretary Rajesh Kumar Singh gives big update on Kaveri Jet Engine

"The decision..." India's Defence Secretary Rajesh Kumar Singh gives big update on Kaveri Jet Engine

Re: Kaveri & Aero-Engine: News & Discussion

The biggest buffoons for India are the 1 exam wonder IAS babus which promises a lot but under delivers or not at all delivers. These guys/gals are the worst blight on the nation. Which initiative have they taken to improve the nation, mind you the entire administration apparatus is under them. Have they inducted any modern methods, computers, workflow mgmt software, decision making (why they made a decision for any of their projects and what factors were considered), worst communication skills, not subject to people feedback on how they operate, convoluted processes which are a nightmare to figure out for the ordinary citizen and of course corruption to the hilt. These fellows are injected everywhere and they are clueless on technology and how to advance.

Re: Kaveri & Aero-Engine: News & Discussion

In a country like China, these kind of people will be demoted to be Chowkidar outside the aircraft plant, for making such a statement. Only in India, they get away with doing damage with 0 contribution.

Re: Kaveri & Aero-Engine: News & Discussion

After the 6th engine the U.S will squeeze the supply. It will trickle down and eventually stop in few months time. They will calculate it to trickle keeping hope and letting the delay as much as possible. Eventually within a year (if Trump can show some patience), it will stop completely. Since the trade deal is not happening at the whims of Americans, this could happen much sooner. Demand will come to purchase F-16s. On denying, Pak will be supplied with the largest F-16s for more Bitcoin deals and Oil land handover. Then alarm bells will start ringing inside many heads in New Delhi. French tasting blood will demand many years of integration and testing the French engines for exorbitant price. They will also pitch few more Rafales until the French engine is integrated and tested on Tejas MK1A. That will set the same Babus debating on it for another few years. Russians will jump in and suggest Brahmos core for the engine. Then there will be a bid announced on who should win the deal. Half way through the French will withdraw leaving only Russian option leading to single vendor deal. Meanwhile Rajanth Singh who has lost his remaining hair will ask IAF to go for the underpowered Kaveri engine and fly Tejas with them for the Time being. Meanwhile DRDO will be urgently pressed to come up with follow on Kaveri engines that can power the Tejas. All the tender, selection of private players who can contribute will take years. French meanwhile will be demanding more money for the program to handover Tech transfer to DRDO for the new engine affecting the AMCA program as well. Meanwhile IAF chief will state the urgent need to import aircrafts to fill the gap. Eventually all our programs are grounded and we will be back to another round of MMRCA tender.

Last edited by uddu on 28 Nov 2025 22:15, edited 1 time in total.

Re: Kaveri & Aero-Engine: News & Discussion

I have a feeling that the Defense secretary may be believing that the Joint Venture engine can be used in Tejas MK1A as well. just plug and play.

Re: Kaveri & Aero-Engine: News & Discussion

This French Safran deal is about kicking the can down the road. The problem of engine is immediate. Kaveri and its derivatives are absolutely needed by India. Even a slightly underpowered engine is much better than importing engines (which is subject to sanctions). Using incremental improvements it can be scaled up further. Our blighted babus need to sanction in house test bed and aircraft for testing engines. This is minimum requirement if India needs to be independent of Videshi maal. Defence mantriji Rajnath and defence secretary are not in synch with this objective. They are still "hoping" instead of delivering value. Lots of backend deals are what Babus want to make their lives easier and unaccountable. The financial implications are even worse for India.

Re: Kaveri & Aero-Engine: News & Discussion

Good one, Bala.

Re: Kaveri & Aero-Engine: News & Discussion

Why all R&D on aircraft engines is concentrated solely in the public sector? That is like using only one arm (and the weaker one) to do the fighting. Why not establish a National Aircraft Engine Mission, with cream of private sector (Bharat Forge, etc.), DRDO, ISRO, and IITs coming together to do joint research and bring their own expertise to the table to crack the problem? I think they can build a functioning prototype in just 5 to 10 years.

Re: Kaveri & Aero-Engine: News & Discussion

Good one udduji … exactly how this will play out. Maybe not at 6th engine but will happen for sure.

You forgot some additional steps:

Comments like Mk 2 is a one winged peregrine falcon or “we don’t have plan a or c or d” (plan B was never there) from IAF brass

HAL releases nice PowerPoints and models of SLEEK , FAST or similar acronymed aircraft models that never even make it out of Photoshop stage

HAL claiming 40/48/64 aircraft per year assembly line (another matter of deliveries)

You forgot some additional steps:

Comments like Mk 2 is a one winged peregrine falcon or “we don’t have plan a or c or d” (plan B was never there) from IAF brass

HAL releases nice PowerPoints and models of SLEEK , FAST or similar acronymed aircraft models that never even make it out of Photoshop stage

HAL claiming 40/48/64 aircraft per year assembly line (another matter of deliveries)

Re: Kaveri & Aero-Engine: News & Discussion

Maitya-ji can correct me if I am wrong, but I doubt (even if we opened the money purse and poured funds into the Kaveri program as of TODAY) that we will have a certified turbofan even after five years. I am more inclined to go with 10 years, but Maitya-ji can provide a more accurate timeline.

In terms of air power, we are staring at a fairly bleak future. The only (short term) viable path forward is the following;

1) Complete the Super Sukhoi upgrade on the current Rambha Fleet

2) Build additional Rambhas (around 40 more). Highly unlikely this will happen, due to the MRFA fiasco.

3) Integrate GE F404 turbofans, as and when they come to the Tejas Mk1A airframes.

Nothing else (incl the MRFA) will arrive in any decent time. The first MRFA will arrive - at minimum - three years after contract signature.

In terms of air power, we are staring at a fairly bleak future. The only (short term) viable path forward is the following;

1) Complete the Super Sukhoi upgrade on the current Rambha Fleet

2) Build additional Rambhas (around 40 more). Highly unlikely this will happen, due to the MRFA fiasco.

3) Integrate GE F404 turbofans, as and when they come to the Tejas Mk1A airframes.

Nothing else (incl the MRFA) will arrive in any decent time. The first MRFA will arrive - at minimum - three years after contract signature.

Re: Kaveri & Aero-Engine: News & Discussion

Not so sure about that. The article below mentions some tech transfer from Safran in engine management for the development of the AFADEC. It looks like we are not aware of all the gaps that exist in making an engine ready for integration with an airplane. I suspect there isn an effort via the Safran and GE deals to speed up access to some of this tech that is missing.

A-FADEC

Re: Kaveri & Aero-Engine: News & Discussion

Once again I am tempted to repeat

One squadron of Rafale every year till AMCA is available

One squadron of Rafale every year till AMCA is available