Ramana sir, would not be better to entrust this to a private enterprise that has experience in building large industrial equipment like turbines? While turbines are the inverse in energy terms to jet engines, the expertise of the L&T folks in technology and especially project and product management can prove crucial to success.ramana wrote:skumar, From what little I know of jet engine design Kaveri won't deliver anymore without a new core. DRDO chief said we are developing a larger engine.

India's R&D in Defence DRDO, PSUs and Private Sector

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Drdo adrushya

Re: India's R&D in Defence DRDO, PSUs and Private Sector

DRDO NEWS LETTER

April 2020 | volume 40 | issue 04

●TOT of High Power Li-ion Battery Technology for Defence Applications

●DMRL Transfers Rare Earth Permanent Magnets Technology

●Wind Blast Test on Lightweight Integrated Aircrew Helmet and Pressure Breathing Oxygen Mask for Pilots

https://drdo.gov.in/sites/default/files ... 2020_0.pdf

April 2020 | volume 40 | issue 04

●TOT of High Power Li-ion Battery Technology for Defence Applications

●DMRL Transfers Rare Earth Permanent Magnets Technology

●Wind Blast Test on Lightweight Integrated Aircrew Helmet and Pressure Breathing Oxygen Mask for Pilots

https://drdo.gov.in/sites/default/files ... 2020_0.pdf

Re: India's R&D in Defence DRDO, PSUs and Private Sector

DRDO TECH FOCUS

Fire, Explosive and Environment Safety Technologies

VOL 28 | ISSUE 2 | April 2020

https://drdo.gov.in/sites/default/files ... e_2020.pdf

Electro-optical Products and Technologies

Vol 28 | Issue 3 | June 2020

https://drdo.gov.in/sites/default/files ... 202020.pdf

Fire, Explosive and Environment Safety Technologies

VOL 28 | ISSUE 2 | April 2020

https://drdo.gov.in/sites/default/files ... e_2020.pdf

Electro-optical Products and Technologies

Vol 28 | Issue 3 | June 2020

https://drdo.gov.in/sites/default/files ... 202020.pdf

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Achieving Self Reliance through Indigenous R&D by DRDO /Industry - Part I

Achieving Self Reliance through Indigenous R&D by DRDO /Industry - Part II

https://www.vifindia.org/taskforcerepor ... ry-part-II

Courtesy : Vivekananda International Foundation

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Thanks for sharing.jaysimha wrote:DRDO TECH FOCUS

...

Electro-optical Products and Technologies

Vol 28 | Issue 3 | June 2020

https://drdo.gov.in/sites/default/files ... 202020.pdf

Any info if they are doing any work on very small cameras/IR cameras which can be fitted on micro/nano drones?

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Courtesy https://swarajyamag.com/defence/a-pheno ... ft-sinking

Pokhran-II: From Site Selection To Shaft Sinking—A First-Hand Account Of How 113 Engineer Regiment Made 1998 Nuclear Tests Possible

by Major General Mrinal Suman

- Nov 03, 2018, 11:55 am

Snapshot

A first-hand account of 113 Engineer Regiment’s indomitable spirit, determination and ingenuity in digging two 600-foot deep shafts in 1981-82, which made Pokhran II possible in 1998.

Pokhran II took place in May 1998 under Operation Shakti. A total of five tests with weapon grade plutonium were conducted – three on 11 May and two on 13 May. The tests included a 45 kt fusion bomb (also called hydrogen or thermonuclear bomb), a 15 kilo tonne (kt) fission bomb (atomic bomb) and three experimental sub-atomic devices of 0.5, 0.3 and 0.2 kt respectively.

Dr K Santhanam of the Defence Research and Development Organisation (DRDO) was the director for the test site preparations. In an interview to Times Now TV channel in April 2008, he revealed that India had dug two deep shafts at Pokhran in 1981-82. The fission and fusion bombs were placed in these shafts. For sub-atomic tests, use was made of three abandoned dry wells in the near vicinity. These wells had earlier been dug by the villagers and deserted as no water had been struck.

The Indira Gandhi government had decided to carry out tests in 1982-83 and the army was asked to sink the shafts. 113 Engineer Regiment completed the task ahead of schedule but the tests were shelved due to external pressures. More than a decade later, then prime minister P V Narasimha Rao asked the scientists to go ahead with the tests in 1994-95. Unfortunately, the US satellites detected the preparations. Once again, India was forced to abort the tests.

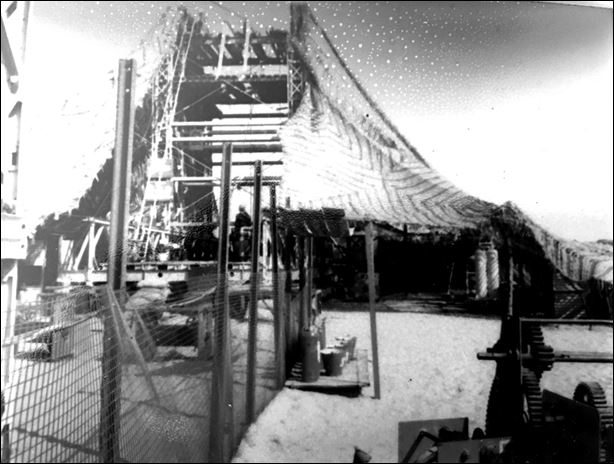

A word about shaft sinking will be in order here. To approach underground mineral seams, a vertical opening (shaft) is provided from the surface to the mining zone. These shafts are used to carry men, material and equipment to the mining zone; as also, to haul the extracted ore to the surface. Being the lifelines of all underground mines, shafts are sunk with exacting technical specifications.

Essentially, a shaft contains a head-frame (tower) to house the hoist; a shaft collar of reinforced concrete to provide foundation support to the head frame and to accommodate mechanism for men, materials and services to enter and exit the shaft; and shaft barrel that continues from the collar to the planned depth. The shaft also carries ducts for the pumping of fresh air, dewatering pipes and electrical fittings. All mining manuals term shaft sinking to be the most dangerous and hazardous task of all mining operations. It requires domain expertise and specialised equipment. There are a handful of shaft sinking companies in the world, normally called ‘sinkers’. All mining companies outsource shaft sinking operations to them.

113 Engineer Regiment, located at Jodhpur, was asked to undertake the task. The regiment was under the command of the late Lt Col KC Dhingra (later rose to the rank of Major General). Col Dhingra was an extremely intelligent officer with phenomenal memory and exceptional capacity for sustained hard work. The regiment was acutely aware of the criticality of the task and the trust that had been reposed in its capability to deliver. It was determined not to let the nation down. I was a Major in the regiment and had the privilege of being involved from the beginning to the culmination of the task.

It was an unprecedented assignment. To sink a shaft hundreds of feet deep with no experience and no equipment was a huge challenge – more so as none of the officers had ever visited a mine or seen a shaft; nor had anyone studied mining engineering which is a specialised course. Although site preparations for Pokhran-I were also carried out by the army engineers, the task was of entirely different genre and did not entail sinking of subterranean shafts ab initio. Pokhran-I was conducted at a much shallower depth, using an abandoned dry well.

Site Selection

It was the month of January 1981. After an exercise in the desert, Col Dhingra asked me to accompany him for an operational reconnaissance. While driving to the Pokhran ranges he told me that the regiment had been tasked to sink a deep shaft of more than 500 feet. Repeatedly stressing the need for secrecy of the mission, he gave out other broad parameters. With maps in our hands, we traversed the ranges a number of times over the next two days to get a feel of its extent and zeroed on to a 9 sq km area that satisfied our security and secrecy concerns. It was well away from the highways and the villages. The aim was to identify a location where the water would pose minimal impediment to the shaft sinking operations. Hence, site selection was a highly critical step. But, how to go about it? We had no knowledge.

Within a week, I was back in the Pokhran area with a team of officers and men for detailed ground reconnaissance. After much scouting and ground survey, we selected four tentative sites that lay in the inter-dunal low-lying areas with least sand overburden. We also approached the nearby villagers to draw benefit from their local knowledge. We told them that the army wanted to establish a permanent camp and was looking for reliable water sources. We showed them the four sites and asked them to advise as to where the water could be found. We, of course, intended to eliminate those sites.

One evening, without informing us, the local headman brought a water diviner from Pokhran town and started appraising the sites. It was a full moon night. Water divining is an esoteric ancient method in which the locals have immense faith. It is believed that the flow of underground water induces some vital currents above the surface and a person with induction attributes can sense them through the movement of a freshly plucked twig. We watched in disbelief while the water diviner announced that none of the sites held abundant water. For us, it was just a gratuitous input of little consequence as the technique lacked scientific authentication.

We approached Central Arid Zone Research Institute (CAZRI) at Jodhpur for help in identifying water sources. They explained to us that the availability of perched aquifers (an underground layer of water-bearing permeable rock, rock fractures or unconsolidated materials) and underground streams depended on the geology and geomorphology of the area. CAZRI readily gave us geologic and topographic maps of the area. We studied them in detail, trying to relate them to the four sites selected by us. However, we were still not confident and sought application of a more exact and scientific method.

After much persuasion, Col Dhingra agreed to seek help of a local hydrogeology agency that specialised in water prospecting for wells. The agency was told the same story i.e. the army was looking for a camp site with a water source. The agency could carry out core drilling for geologic sampling up to 150 feet only. Once again, the core logging declared all the sites ‘unfit for sinking well’, meaning thereby that water was not available in exploitable quantity. Even the seismic survey gave the same report. Though encouraging, the reports were not a clincher as we had to go down to more than 500 feet.

After studying all the inputs (whatever be their worth), we selected two sites. In consultation with the higher authorities, it was decided to attempt digging at more than one site to cater for unforeseen hold-ups. However, as the work progressed, the authorities decided to go ahead with both the shafts.

Sinking of the Shafts

We sank shafts that were over 600 feet deep. The height of Qutub Minar is 240 feet. In other words, the depth of the shafts was two and a half times the height of the Qutub Minar; or, the shafts could have swallowed two and a half Qutub Minars.

The shafts were absolutely vertical in alignment. Looking up from such depths, against the darkness of the shaft walls, one saw a bright disc of sky of dazzling brilliance. It used to be an awe-inspiring spectacle. The night sky presented a sight of celestial blues. Memories of those experiences are still fresh.

Working at such depths is highly challenging. With water flowing along the walls, it is humid and hot. Normally, after 100 feet depth, temperature rises by one degree in every 30 feet. In the absence of fresh air, ventilation ducts are installed for pumping air from top. Simultaneous operation of multiple rock drills produced unbearable din and clouds of dust hanging in the air. Every soldier had to have ear plugs and wear protective eye goggles.

As water was being pumped out in stages, failure of any pump in the chain used to result in tonnes of water falling down on the working party. In case it happened while the drilled-holes were being loaded with explosive, the problems used to get compounded, causing considerable anxiety and delay. Due to a complete lack of any other source of light, everyone had to wear miners lamps on the helmet. One had to master the art of working with these lamps for long hours, having to turn head frequently to focus the beam.

All soldiers had to be repeatedly cautioned about the lethality of the falling objects. To drive home the point, they were shown that even a bolt falling from a height of 600 feet could split open a protective helmet due to its potential energy. Every single implement and tool had to be stringed and tied to prevent accidental fall from hand.

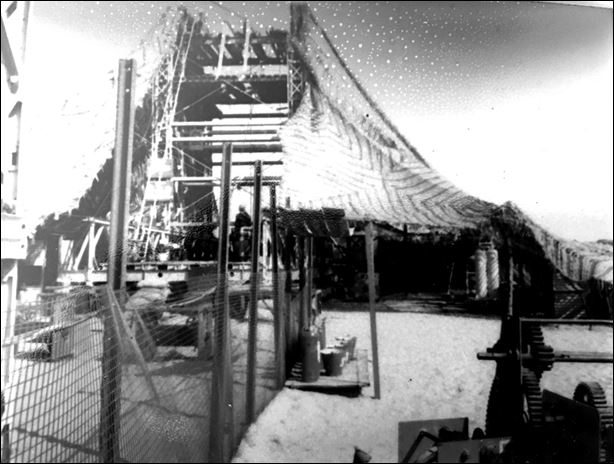

Two task forces were constituted and the work started at both the sites in Feb 1981 end without much fanfare. A small ceremony was held to invoke blessings of Ramdevra, the ruling deity of the desert whom the locals consider to be an incarnation of Lord Krishna. Thereafter, the diameter of the shaft was marked on the ground with pegs, and the digging commenced with picks and shovels. For a few days, hauling of the dug earth was done manually with mortar pans. Thereafter, the unit crane was deployed with a modified coal-tar drum. Soon the crane rope reached its limit. To prevent caving in, revetment of the walls was done with flattened CGI sheets and iron pickets.

We sank shafts that were over 600 feet deep. The height of Qutub Minar is 240 feet. In other words, the depth of the shafts was two and a half times the height of the Qutub Minar; or, the shafts could have swallowed two and a half Qutub Minars.The shafts were absolutely vertical in alignment. Looking up from such depths, against the darkness of the shaft walls, one saw a bright disc of sky of dazzling brilliance. It used to be an awe-inspiring spectacle. The night sky presented a sight of celestial blues. Memories of those experiences are still fresh.Working at such depths is highly challenging. With water flowing along the walls, it is humid and hot. Normally, after 100 feet depth, temperature rises by one degree in every thirty feet. In the absence of fresh air, ventilation ducts are installed for pumping air from top. Simultaneous operation of multiple rock drills produced unbearable din and clouds of dust hanging in the air. Every soldier had to have ear plugs and wear protective eye goggles.

As learnt in field engineering, tripod gantry with blocks and tackles to hoist a pulley system was erected. Reeving was done by threading the winch drum cable of a dozer. A larger semi-elliptical bucket was fabricated for removing earth. Such expedients can at best be of interim help. The dozer cable had limited length and worse, the wire-rope started fraying with strands coming apart. In fact, it was ill-suited for the task as the bucket used to swing wildly due to the wire-rope lacking non-twist construction. Soon the digging came to a standstill.

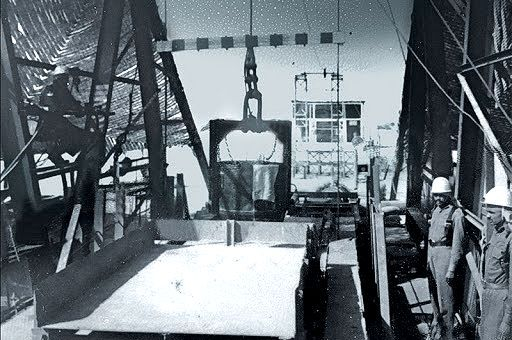

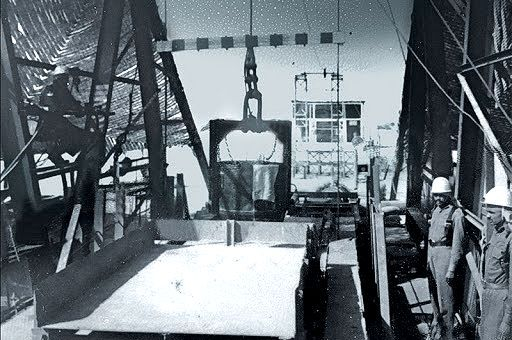

Anticipating the requirement for a proper hoisting arrangement, a team had already been sent to Calcutta to identify and procure a suitable haulage system. After considerable effort, a winder assembly manufactured by a local industrialist was identified. Orders were placed for immediate delivery and operators sent for training. With the imminent arrival of the ground-mounted winder assembly, the head-frames (also called winding tower, poppet head or pit head) were quickly constructed with bailey bridge equipment to house the sheave wheel.

While awaiting arrival of the winders, the time was duly utilised to cast shaft collars (also called the ‘bank’ or ‘deck’) with heavy reinforced concrete in three tiers/levels for required stability. In addition, troops familiarised themselves with the ‘drill and blast method’. A bevy of generators and air-compressors were requisitioned. Captain SB Pendse ingeniously established reliable grids to ensure uninterrupted supply of electricity and compressed air.

As regards the geology and the rock formation of the sites. After having cleared the sand over-burden, we encountered conglomerate consisting of gravel, sand stone and silt stone. Digging was tough as the drill used to get stalled in the bores. We also encountered shale, a fine-grained clastic sedimentary rock. It is a mudstone that is fissile and laminated. Instability of the shaft walls became a matter of concern. Loose or unstable portions often fell down due to the vibrations caused by the drill.

During Pokhran-I, within one month of commencing digging, loose shale strata had fallen on the digging party, killing one and injuring four persons. Criticality of shaft stability was well understood by us. At deeper depths, a cave-in could bury the working party alive. Initially, we tried to anchor wire mesh with rock-bolts on the walls to trap falling stones. It proved to be of little use. Blasts used to loosen rocks along the natural cracks on the walls, uprooting the mesh.

Choice of shaft lining depends on the nature of rock strata. In some shafts, lining is done with precast concrete segments and shotcrete. Concrete is highly reliable but is normally used for shafts that are permanent or long-lasting. It is an expensive and time consuming option. In our case, the shafts were required urgently and for one-off use only. We were at our wit’s end. After much deliberations, we hit upon a unique system of having prefabricated steel jackets in the form of segments of a circle. These could be easily lowered into the shafts and bolted together to form a circular steel liner. Provision had been made to drive rock bolts through them for proper anchoring. Jackets also lent themselves to grouting to block water ingress.

Time for each ‘drill and blast’ cycle varied with the rock formation encountered for drilling and the depth of the shaft. As we went deeper the turnaround time of the haulage bucket increased significantly and removal of rubble took much longer. A standard cycle consisted of the following steps:-

Clearing of the floor of the shaft and construction of a sump in a corner to collect and pump out water.

Drilling of multiple slanting holes of varying depth to create free face with delayed detonators for optimum blast effect.

Filling of the holes with explosive and connecting all detonators through a ring main circuit for firing.

Removal of drills, pumps and other construction equipment out of the shaft.

Firing of the charges.

Removal of the blasted rock (rubble) to obtain the floor face for the next cycle of drilling.

It is a common misconception that the deserts are devoid of subterranean water. It is not so. It is just that the water’s quality, quantity and availability (at deep depths) does not lend itself to economic exploitability. On encountering substantial quantity of water, we learnt that the Air Operated Double Diaphragm (AODD) pumps were the only answer. An AODD pump is a type of positive displacement pump that uses compressed air as a power source, using reciprocating elastomeric diaphragms and check valves to pump fluid. The liquid chambers are filled and emptied by fluid that is drawn through a common inlet and discharged through a single outlet.These pumps were not available in India and import would have taken long as also compromised secrecy. Adopting the proverbial ‘juggad’ method, we visited scrap markets near a few mines to procure discarded, non-functional and scrapped AODD pumps. These were dismantled for study and to identify different components. A local workshop was roped in to duplicate them. After a few failures, we did manage to assemble a reasonably efficient pump. However, the problem of obtaining elastomeric diaphragms persisted till we located a small entrepreneur in Thane who agreed to develop it for us. Once we had AODD pumps, there was no looking back.

Misfire used to be the most dreaded nightmare. A single defective detonator could fail the entire circuit and the charges would remain unfired. In that case, one had to wait for two hours before entering the shaft, lest a stray spark set the explosive off. Thereafter, the senior-most officer at the site had to go down to the base of the shaft to remove all the charges. By then the shaft used to be flooded with water. It was a highly risky task. The water used to be murky and the officer had to go underwater to locate all the charges by touch. The whole ring main circuit had to be dismantled and all detonators brought over-ground for replacement. Every such misfire invariably put our progress back by a day.

At each shaft, the work was carried out round the clock in shifts. Daily progress report was being submitted to the authorities. After every 10 feet of depth, we had to pause to stabilise the shaft walls with steel jackets and rock-bolts.

We encountered water seepage at 60 feet depth. Although the quantity of inflow was limited, it still posed problems in digging. It had to be collected in a sump and pumped out at intervals. Only electricity driven submersible pumps possess high pump-head. However, they cannot be used in the shafts due to the risk of electrocution of the working party. During Pokhran-I (January 1974), ingress of water had stalled the progress on the shaft within three months of commencing digging. The problem could not be solved even by the scientists. In the end, the incomplete shaft had to be abandoned. As there was no time for attempting a fresh shaft, a dry abandoned well was prepared for the test in May 1974.

We were totally at a loss. To learn about the methodology to pump out water, Col Dhingra and the two shaft commanders (Major S Jagannathan and I) made a quick visit to Khetri copper mines and Zawar zinc mines. There, for the first time, we saw the air operated double diaphragm (AODD) pumps and immediately realised their indispensability. Steps were initiated to procure them. Their receipt helped us go full steam ahead. There was no stopping us thereafter. With the maximum head of AODD pumps being limited, we evolved a system of pumping out water by stages. As we went down, additional stages were erected.

The scientists in army uniforms used to visit us periodically to study the progress and specify additional facilities for tests. They expressed the requirement of niches/alcoves at various depths of the shafts for placing monitoring instruments. Cabling network was also indicated. A tall observation tower was constructed at a distance with crib-piers.

On reaching the stipulated depth, we were asked to make a side chamber of a large bedroom size. As a powerful nuclear device is always placed under natural rock strata to contain blast effect, thermal radiation and radio-active fallout, such a requirement was already anticipated by us. We knew that our shafts would finally be L-shaped. The side chambers was duly completed without much difficulty and completion report submitted.

Soon, we received mock-ups of the nuclear devices. They were lowered and placed in the side chambers to ascertain suitability of the hoisting mechanism. The scientists had demanded that the chambers should be ‘without a drop of water’. We had to harness considerable ingenuity to achieve that. To demonstrate the dryness of the chamber, we laid a carpet on the chamber’s floor and gave tea to the scientists from a thermos flask. The scientists were keyed up and ecstatic. One of them poignantly commented, “Oh my God. This is the most memorable cup of tea – over 600 feet underground”.

The Disappointment: The Tests That Were Not To Be

General K V Krishna Rao, Chief of the Army Staff, also visited the shafts. He could not believe that the army engineers had completed the task without any external help. After visiting both the shafts, he told Col Dhingra, “I knew it was a tough assignment but can appreciate its magnitude only after this visit. You have amazed me. You must be a very proud commanding officer. Do you realise that your unit is writing the history of India.” Col Dhingra conveyed the Chief’s words to both the shaft commanders.

Visits by the scientists became more frequent. Things were moving fast. The atmosphere was charged with excitement. Trial with mock-ups was seen by us as a affirmative sign. We were upbeat and thought that the tests were imminent – it was a question of ‘any day’. However, it was not to be. We waited for days and weeks without the much awaited bang. With great disappointment, we learnt that the government had decided not to go ahead with the tests. It was ruled that the shafts be maintained and dewatered regularly with submersible pumps, awaiting another opportune moment for the tests.

Our regiment had been in the desert for over three years. We were asked to hand over the maintenance of the completed shafts to another regiment. Various regiments continued with the maintenance till 1998 when they were finally put to nuclear tests. We learnt of the tests with immense pride but somewhere down in our hearts there was a tinge of disappointment. We were not destined to be a part of the historical event.

Sinking the shafts of over 600 feet depth, lining the walls and preparing side chambers in such a compressed time frame had been a monumental achievement. The world over, the average rate of sinking shafts with ‘drill and blast’ method is pegged at 3 feet per week by the professional companies possessing decades of experience, consummate expertise and latest equipment. We, the soldiers of 113 Engineer Regiment, had no experience, no knowledge and no equipment. We did struggle initially but our perseverance helped us overcome all challenges. It was an unparalleled feat by all standards.

According to the information available in public domain, no country in the world has ever asked its army engineers to dig deep shafts for the nuclear tests. As India has declared self-imposed moratorium on nuclear tests, need for deep shafts will never arise again. In other words, the feat of 113 Engineer Regiment will remain unparalleled. As General Krishna Rao had stated, 113 Engineer Regiment contributed to the history of India: a unique distinction indeed. The regiment has earned the appellation “Shaft Sinkers to Nuclear India”.

(Courtesy FORCE)

The author commanded his regiment in the Kargil-Siachen sector and was the Task Force Commander at Pokharan for sinking shafts for the nuclear tests. He is a prolific writer and is considered to be the foremost expert on myriad aspects of India’s defence industry, procurement regime and offsets.

Pokhran-II: From Site Selection To Shaft Sinking—A First-Hand Account Of How 113 Engineer Regiment Made 1998 Nuclear Tests Possible

by Major General Mrinal Suman

- Nov 03, 2018, 11:55 am

Snapshot

A first-hand account of 113 Engineer Regiment’s indomitable spirit, determination and ingenuity in digging two 600-foot deep shafts in 1981-82, which made Pokhran II possible in 1998.

Pokhran II took place in May 1998 under Operation Shakti. A total of five tests with weapon grade plutonium were conducted – three on 11 May and two on 13 May. The tests included a 45 kt fusion bomb (also called hydrogen or thermonuclear bomb), a 15 kilo tonne (kt) fission bomb (atomic bomb) and three experimental sub-atomic devices of 0.5, 0.3 and 0.2 kt respectively.

Dr K Santhanam of the Defence Research and Development Organisation (DRDO) was the director for the test site preparations. In an interview to Times Now TV channel in April 2008, he revealed that India had dug two deep shafts at Pokhran in 1981-82. The fission and fusion bombs were placed in these shafts. For sub-atomic tests, use was made of three abandoned dry wells in the near vicinity. These wells had earlier been dug by the villagers and deserted as no water had been struck.

The Indira Gandhi government had decided to carry out tests in 1982-83 and the army was asked to sink the shafts. 113 Engineer Regiment completed the task ahead of schedule but the tests were shelved due to external pressures. More than a decade later, then prime minister P V Narasimha Rao asked the scientists to go ahead with the tests in 1994-95. Unfortunately, the US satellites detected the preparations. Once again, India was forced to abort the tests.

A word about shaft sinking will be in order here. To approach underground mineral seams, a vertical opening (shaft) is provided from the surface to the mining zone. These shafts are used to carry men, material and equipment to the mining zone; as also, to haul the extracted ore to the surface. Being the lifelines of all underground mines, shafts are sunk with exacting technical specifications.

Essentially, a shaft contains a head-frame (tower) to house the hoist; a shaft collar of reinforced concrete to provide foundation support to the head frame and to accommodate mechanism for men, materials and services to enter and exit the shaft; and shaft barrel that continues from the collar to the planned depth. The shaft also carries ducts for the pumping of fresh air, dewatering pipes and electrical fittings. All mining manuals term shaft sinking to be the most dangerous and hazardous task of all mining operations. It requires domain expertise and specialised equipment. There are a handful of shaft sinking companies in the world, normally called ‘sinkers’. All mining companies outsource shaft sinking operations to them.

113 Engineer Regiment, located at Jodhpur, was asked to undertake the task. The regiment was under the command of the late Lt Col KC Dhingra (later rose to the rank of Major General). Col Dhingra was an extremely intelligent officer with phenomenal memory and exceptional capacity for sustained hard work. The regiment was acutely aware of the criticality of the task and the trust that had been reposed in its capability to deliver. It was determined not to let the nation down. I was a Major in the regiment and had the privilege of being involved from the beginning to the culmination of the task.

It was an unprecedented assignment. To sink a shaft hundreds of feet deep with no experience and no equipment was a huge challenge – more so as none of the officers had ever visited a mine or seen a shaft; nor had anyone studied mining engineering which is a specialised course. Although site preparations for Pokhran-I were also carried out by the army engineers, the task was of entirely different genre and did not entail sinking of subterranean shafts ab initio. Pokhran-I was conducted at a much shallower depth, using an abandoned dry well.

Site Selection

It was the month of January 1981. After an exercise in the desert, Col Dhingra asked me to accompany him for an operational reconnaissance. While driving to the Pokhran ranges he told me that the regiment had been tasked to sink a deep shaft of more than 500 feet. Repeatedly stressing the need for secrecy of the mission, he gave out other broad parameters. With maps in our hands, we traversed the ranges a number of times over the next two days to get a feel of its extent and zeroed on to a 9 sq km area that satisfied our security and secrecy concerns. It was well away from the highways and the villages. The aim was to identify a location where the water would pose minimal impediment to the shaft sinking operations. Hence, site selection was a highly critical step. But, how to go about it? We had no knowledge.

Within a week, I was back in the Pokhran area with a team of officers and men for detailed ground reconnaissance. After much scouting and ground survey, we selected four tentative sites that lay in the inter-dunal low-lying areas with least sand overburden. We also approached the nearby villagers to draw benefit from their local knowledge. We told them that the army wanted to establish a permanent camp and was looking for reliable water sources. We showed them the four sites and asked them to advise as to where the water could be found. We, of course, intended to eliminate those sites.

One evening, without informing us, the local headman brought a water diviner from Pokhran town and started appraising the sites. It was a full moon night. Water divining is an esoteric ancient method in which the locals have immense faith. It is believed that the flow of underground water induces some vital currents above the surface and a person with induction attributes can sense them through the movement of a freshly plucked twig. We watched in disbelief while the water diviner announced that none of the sites held abundant water. For us, it was just a gratuitous input of little consequence as the technique lacked scientific authentication.

We approached Central Arid Zone Research Institute (CAZRI) at Jodhpur for help in identifying water sources. They explained to us that the availability of perched aquifers (an underground layer of water-bearing permeable rock, rock fractures or unconsolidated materials) and underground streams depended on the geology and geomorphology of the area. CAZRI readily gave us geologic and topographic maps of the area. We studied them in detail, trying to relate them to the four sites selected by us. However, we were still not confident and sought application of a more exact and scientific method.

After much persuasion, Col Dhingra agreed to seek help of a local hydrogeology agency that specialised in water prospecting for wells. The agency was told the same story i.e. the army was looking for a camp site with a water source. The agency could carry out core drilling for geologic sampling up to 150 feet only. Once again, the core logging declared all the sites ‘unfit for sinking well’, meaning thereby that water was not available in exploitable quantity. Even the seismic survey gave the same report. Though encouraging, the reports were not a clincher as we had to go down to more than 500 feet.

After studying all the inputs (whatever be their worth), we selected two sites. In consultation with the higher authorities, it was decided to attempt digging at more than one site to cater for unforeseen hold-ups. However, as the work progressed, the authorities decided to go ahead with both the shafts.

Sinking of the Shafts

We sank shafts that were over 600 feet deep. The height of Qutub Minar is 240 feet. In other words, the depth of the shafts was two and a half times the height of the Qutub Minar; or, the shafts could have swallowed two and a half Qutub Minars.

The shafts were absolutely vertical in alignment. Looking up from such depths, against the darkness of the shaft walls, one saw a bright disc of sky of dazzling brilliance. It used to be an awe-inspiring spectacle. The night sky presented a sight of celestial blues. Memories of those experiences are still fresh.

Working at such depths is highly challenging. With water flowing along the walls, it is humid and hot. Normally, after 100 feet depth, temperature rises by one degree in every 30 feet. In the absence of fresh air, ventilation ducts are installed for pumping air from top. Simultaneous operation of multiple rock drills produced unbearable din and clouds of dust hanging in the air. Every soldier had to have ear plugs and wear protective eye goggles.

As water was being pumped out in stages, failure of any pump in the chain used to result in tonnes of water falling down on the working party. In case it happened while the drilled-holes were being loaded with explosive, the problems used to get compounded, causing considerable anxiety and delay. Due to a complete lack of any other source of light, everyone had to wear miners lamps on the helmet. One had to master the art of working with these lamps for long hours, having to turn head frequently to focus the beam.

All soldiers had to be repeatedly cautioned about the lethality of the falling objects. To drive home the point, they were shown that even a bolt falling from a height of 600 feet could split open a protective helmet due to its potential energy. Every single implement and tool had to be stringed and tied to prevent accidental fall from hand.

Two task forces were constituted and the work started at both the sites in Feb 1981 end without much fanfare. A small ceremony was held to invoke blessings of Ramdevra, the ruling deity of the desert whom the locals consider to be an incarnation of Lord Krishna. Thereafter, the diameter of the shaft was marked on the ground with pegs, and the digging commenced with picks and shovels. For a few days, hauling of the dug earth was done manually with mortar pans. Thereafter, the unit crane was deployed with a modified coal-tar drum. Soon the crane rope reached its limit. To prevent caving in, revetment of the walls was done with flattened CGI sheets and iron pickets.

We sank shafts that were over 600 feet deep. The height of Qutub Minar is 240 feet. In other words, the depth of the shafts was two and a half times the height of the Qutub Minar; or, the shafts could have swallowed two and a half Qutub Minars.The shafts were absolutely vertical in alignment. Looking up from such depths, against the darkness of the shaft walls, one saw a bright disc of sky of dazzling brilliance. It used to be an awe-inspiring spectacle. The night sky presented a sight of celestial blues. Memories of those experiences are still fresh.Working at such depths is highly challenging. With water flowing along the walls, it is humid and hot. Normally, after 100 feet depth, temperature rises by one degree in every thirty feet. In the absence of fresh air, ventilation ducts are installed for pumping air from top. Simultaneous operation of multiple rock drills produced unbearable din and clouds of dust hanging in the air. Every soldier had to have ear plugs and wear protective eye goggles.

As learnt in field engineering, tripod gantry with blocks and tackles to hoist a pulley system was erected. Reeving was done by threading the winch drum cable of a dozer. A larger semi-elliptical bucket was fabricated for removing earth. Such expedients can at best be of interim help. The dozer cable had limited length and worse, the wire-rope started fraying with strands coming apart. In fact, it was ill-suited for the task as the bucket used to swing wildly due to the wire-rope lacking non-twist construction. Soon the digging came to a standstill.

Anticipating the requirement for a proper hoisting arrangement, a team had already been sent to Calcutta to identify and procure a suitable haulage system. After considerable effort, a winder assembly manufactured by a local industrialist was identified. Orders were placed for immediate delivery and operators sent for training. With the imminent arrival of the ground-mounted winder assembly, the head-frames (also called winding tower, poppet head or pit head) were quickly constructed with bailey bridge equipment to house the sheave wheel.

While awaiting arrival of the winders, the time was duly utilised to cast shaft collars (also called the ‘bank’ or ‘deck’) with heavy reinforced concrete in three tiers/levels for required stability. In addition, troops familiarised themselves with the ‘drill and blast method’. A bevy of generators and air-compressors were requisitioned. Captain SB Pendse ingeniously established reliable grids to ensure uninterrupted supply of electricity and compressed air.

As regards the geology and the rock formation of the sites. After having cleared the sand over-burden, we encountered conglomerate consisting of gravel, sand stone and silt stone. Digging was tough as the drill used to get stalled in the bores. We also encountered shale, a fine-grained clastic sedimentary rock. It is a mudstone that is fissile and laminated. Instability of the shaft walls became a matter of concern. Loose or unstable portions often fell down due to the vibrations caused by the drill.

During Pokhran-I, within one month of commencing digging, loose shale strata had fallen on the digging party, killing one and injuring four persons. Criticality of shaft stability was well understood by us. At deeper depths, a cave-in could bury the working party alive. Initially, we tried to anchor wire mesh with rock-bolts on the walls to trap falling stones. It proved to be of little use. Blasts used to loosen rocks along the natural cracks on the walls, uprooting the mesh.

Choice of shaft lining depends on the nature of rock strata. In some shafts, lining is done with precast concrete segments and shotcrete. Concrete is highly reliable but is normally used for shafts that are permanent or long-lasting. It is an expensive and time consuming option. In our case, the shafts were required urgently and for one-off use only. We were at our wit’s end. After much deliberations, we hit upon a unique system of having prefabricated steel jackets in the form of segments of a circle. These could be easily lowered into the shafts and bolted together to form a circular steel liner. Provision had been made to drive rock bolts through them for proper anchoring. Jackets also lent themselves to grouting to block water ingress.

Time for each ‘drill and blast’ cycle varied with the rock formation encountered for drilling and the depth of the shaft. As we went deeper the turnaround time of the haulage bucket increased significantly and removal of rubble took much longer. A standard cycle consisted of the following steps:-

Clearing of the floor of the shaft and construction of a sump in a corner to collect and pump out water.

Drilling of multiple slanting holes of varying depth to create free face with delayed detonators for optimum blast effect.

Filling of the holes with explosive and connecting all detonators through a ring main circuit for firing.

Removal of drills, pumps and other construction equipment out of the shaft.

Firing of the charges.

Removal of the blasted rock (rubble) to obtain the floor face for the next cycle of drilling.

It is a common misconception that the deserts are devoid of subterranean water. It is not so. It is just that the water’s quality, quantity and availability (at deep depths) does not lend itself to economic exploitability. On encountering substantial quantity of water, we learnt that the Air Operated Double Diaphragm (AODD) pumps were the only answer. An AODD pump is a type of positive displacement pump that uses compressed air as a power source, using reciprocating elastomeric diaphragms and check valves to pump fluid. The liquid chambers are filled and emptied by fluid that is drawn through a common inlet and discharged through a single outlet.These pumps were not available in India and import would have taken long as also compromised secrecy. Adopting the proverbial ‘juggad’ method, we visited scrap markets near a few mines to procure discarded, non-functional and scrapped AODD pumps. These were dismantled for study and to identify different components. A local workshop was roped in to duplicate them. After a few failures, we did manage to assemble a reasonably efficient pump. However, the problem of obtaining elastomeric diaphragms persisted till we located a small entrepreneur in Thane who agreed to develop it for us. Once we had AODD pumps, there was no looking back.

Misfire used to be the most dreaded nightmare. A single defective detonator could fail the entire circuit and the charges would remain unfired. In that case, one had to wait for two hours before entering the shaft, lest a stray spark set the explosive off. Thereafter, the senior-most officer at the site had to go down to the base of the shaft to remove all the charges. By then the shaft used to be flooded with water. It was a highly risky task. The water used to be murky and the officer had to go underwater to locate all the charges by touch. The whole ring main circuit had to be dismantled and all detonators brought over-ground for replacement. Every such misfire invariably put our progress back by a day.

At each shaft, the work was carried out round the clock in shifts. Daily progress report was being submitted to the authorities. After every 10 feet of depth, we had to pause to stabilise the shaft walls with steel jackets and rock-bolts.

We encountered water seepage at 60 feet depth. Although the quantity of inflow was limited, it still posed problems in digging. It had to be collected in a sump and pumped out at intervals. Only electricity driven submersible pumps possess high pump-head. However, they cannot be used in the shafts due to the risk of electrocution of the working party. During Pokhran-I (January 1974), ingress of water had stalled the progress on the shaft within three months of commencing digging. The problem could not be solved even by the scientists. In the end, the incomplete shaft had to be abandoned. As there was no time for attempting a fresh shaft, a dry abandoned well was prepared for the test in May 1974.

We were totally at a loss. To learn about the methodology to pump out water, Col Dhingra and the two shaft commanders (Major S Jagannathan and I) made a quick visit to Khetri copper mines and Zawar zinc mines. There, for the first time, we saw the air operated double diaphragm (AODD) pumps and immediately realised their indispensability. Steps were initiated to procure them. Their receipt helped us go full steam ahead. There was no stopping us thereafter. With the maximum head of AODD pumps being limited, we evolved a system of pumping out water by stages. As we went down, additional stages were erected.

The scientists in army uniforms used to visit us periodically to study the progress and specify additional facilities for tests. They expressed the requirement of niches/alcoves at various depths of the shafts for placing monitoring instruments. Cabling network was also indicated. A tall observation tower was constructed at a distance with crib-piers.

On reaching the stipulated depth, we were asked to make a side chamber of a large bedroom size. As a powerful nuclear device is always placed under natural rock strata to contain blast effect, thermal radiation and radio-active fallout, such a requirement was already anticipated by us. We knew that our shafts would finally be L-shaped. The side chambers was duly completed without much difficulty and completion report submitted.

Soon, we received mock-ups of the nuclear devices. They were lowered and placed in the side chambers to ascertain suitability of the hoisting mechanism. The scientists had demanded that the chambers should be ‘without a drop of water’. We had to harness considerable ingenuity to achieve that. To demonstrate the dryness of the chamber, we laid a carpet on the chamber’s floor and gave tea to the scientists from a thermos flask. The scientists were keyed up and ecstatic. One of them poignantly commented, “Oh my God. This is the most memorable cup of tea – over 600 feet underground”.

The Disappointment: The Tests That Were Not To Be

General K V Krishna Rao, Chief of the Army Staff, also visited the shafts. He could not believe that the army engineers had completed the task without any external help. After visiting both the shafts, he told Col Dhingra, “I knew it was a tough assignment but can appreciate its magnitude only after this visit. You have amazed me. You must be a very proud commanding officer. Do you realise that your unit is writing the history of India.” Col Dhingra conveyed the Chief’s words to both the shaft commanders.

Visits by the scientists became more frequent. Things were moving fast. The atmosphere was charged with excitement. Trial with mock-ups was seen by us as a affirmative sign. We were upbeat and thought that the tests were imminent – it was a question of ‘any day’. However, it was not to be. We waited for days and weeks without the much awaited bang. With great disappointment, we learnt that the government had decided not to go ahead with the tests. It was ruled that the shafts be maintained and dewatered regularly with submersible pumps, awaiting another opportune moment for the tests.

Our regiment had been in the desert for over three years. We were asked to hand over the maintenance of the completed shafts to another regiment. Various regiments continued with the maintenance till 1998 when they were finally put to nuclear tests. We learnt of the tests with immense pride but somewhere down in our hearts there was a tinge of disappointment. We were not destined to be a part of the historical event.

Sinking the shafts of over 600 feet depth, lining the walls and preparing side chambers in such a compressed time frame had been a monumental achievement. The world over, the average rate of sinking shafts with ‘drill and blast’ method is pegged at 3 feet per week by the professional companies possessing decades of experience, consummate expertise and latest equipment. We, the soldiers of 113 Engineer Regiment, had no experience, no knowledge and no equipment. We did struggle initially but our perseverance helped us overcome all challenges. It was an unparalleled feat by all standards.

According to the information available in public domain, no country in the world has ever asked its army engineers to dig deep shafts for the nuclear tests. As India has declared self-imposed moratorium on nuclear tests, need for deep shafts will never arise again. In other words, the feat of 113 Engineer Regiment will remain unparalleled. As General Krishna Rao had stated, 113 Engineer Regiment contributed to the history of India: a unique distinction indeed. The regiment has earned the appellation “Shaft Sinkers to Nuclear India”.

(Courtesy FORCE)

The author commanded his regiment in the Kargil-Siachen sector and was the Task Force Commander at Pokharan for sinking shafts for the nuclear tests. He is a prolific writer and is considered to be the foremost expert on myriad aspects of India’s defence industry, procurement regime and offsets.

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Shaun, Please post in Imdian Army History thread also.

Re: India's R&D in Defence DRDO, PSUs and Private Sector

The last paragraph is delusional.shaun wrote:Courtesy https://swarajyamag.com/defence/a-pheno ... ft-sinking

Pokhran-II: From Site Selection To Shaft Sinking—A First-Hand Account Of How 113 Engineer Regiment Made 1998 Nuclear Tests Possible

by Major General Mrinal Suman

....

According to the information available in public domain, no country in the world has ever asked its army engineers to dig deep shafts for the nuclear tests. As India has declared self-imposed moratorium on nuclear tests, need for deep shafts will never arise again. In other words, the feat of 113 Engineer Regiment will remain unparalleled. As General Krishna Rao had stated, 113 Engineer Regiment contributed to the history of India: a unique distinction indeed. The regiment has earned the appellation “Shaft Sinkers to Nuclear India”.

Imprints opposite meaning of nuke test moratorium in reader's mind

Moratorium definition == temporary prohibition of an activity.

It DOES NOT mean permanent prohibition of the activity.

Last edited by JayS on 01 Jun 2020 09:14, edited 1 time in total.

Reason: Edited - I think you made your point well, without that last sentence too.

Reason: Edited - I think you made your point well, without that last sentence too.

Re: India's R&D in Defence DRDO, PSUs and Private Sector

https://indianarmy.nic.in/makeinindia/i ... WixTuh1Q==

Army Design Bureau

COMPENDIUM OF PROBLEM DEFINITION STATEMENTS volume 5 2020

CPDS_2020_ADB

https://indianarmy.nic.in/makeinindia/CPDS_2020_ADB.pdf

Army Design Bureau

COMPENDIUM OF PROBLEM DEFINITION STATEMENTS volume 5 2020

CPDS_2020_ADB

https://indianarmy.nic.in/makeinindia/CPDS_2020_ADB.pdf

-

ashishvikas

- BRFite

- Posts: 866

- Joined: 17 Oct 2016 14:18

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Amethi AK-203 factory unlikely to start operations in 2020

As per the plan, the OFB-Kalashnikov joint venture (JV) was to arrive at a fair price for setting up and producing almost seven lakh rifles by May-end.

https://m.economictimes.com/news/defenc ... ssion=true

As per the plan, the OFB-Kalashnikov joint venture (JV) was to arrive at a fair price for setting up and producing almost seven lakh rifles by May-end.

https://m.economictimes.com/news/defenc ... ssion=true

-

ashishvikas

- BRFite

- Posts: 866

- Joined: 17 Oct 2016 14:18

Re: India's R&D in Defence DRDO, PSUs and Private Sector

82,000 OFB staff to go on indefinite strike against corporatisation plan

By Pradip R Sagar

https://www.theweek.in/news/biz-tech/20 ... -plan.html

By Pradip R Sagar

https://www.theweek.in/news/biz-tech/20 ... -plan.html

A day after the ministry of defence placed an order worth over Rs 1,000 crore for infantry vehicles, 82,000 employees of ordnance factories have decided to go on indefinite strike.

Over 82,000 employees working in 41 ordnance factories have decided to go on indefinite strike against the government’s decision to implement corporatisation of the Ordnance Factory Board (OFB). It is the first setback to Prime Minister Narendra Modi's announcements under the "Atmanirbhar Bharat Abhiyan" aimed to boost the economy in the post-COVID-19 era.

The decision for a strike came a day after the ministry of defence placed an order for 156 upgraded BMP infantry combat vehicles valued, at Rs. 1,094 crore, with the OFB. These infantry combat vehicles will be manufactured by Ordnance Factory, Medak, in Telangana with a contract completion target by 2023.

"With induction of these 156 BMP infantry combat vehicles, the existing deficiency in the mechanised infantry battalions will be mitigated and the combat capability of the Army will be further enhanced," a defence ministry official said, while placing the order.

On May 16, while announcing the fourth tranche of the Rs. 20 lakh crore financial relief package, Union Finance Minister Nirmala Sitharaman announced the government's decision of corporatise the Ordnance Factory Board (OFB), arguing that the move is aimed at improving autonomy, accountability and efficiency in ordnance supplies. She added that in the near future, the OFB factories could be listed in the markets to bring in transparency in their operations.

On Wednesday, federations of defence civilian employees took a collective decision to go ahead with an indefinite strike against the government decision, which they called as "arbitrary, illegal and unjustified".

In a joint statement issued by three recognised federations—All India Defence Employees Federation, Indian National Defence Worker's Federation and Bhartiya Pratiraksha Mazdoor Sangh—the protesting workers claimed that the government move is against the agreement between the federations and the ministry of defence in the past.

"Four successive defence ministers of the country including George Fernandes, Pranab Mukherjee, A.K. Antony and Manohar Parrikar have given written commitments that the Ordnance factories would not be corporatised. The present decision of the government is against all these assurances and agreements," C. Srikumar, general secretary, All India Defence Employees Federation (AIDEF), said.

He said that the date of commencement of indefinite strike will be taken soon after strike ballot throughout the country.

Defence unions also claimed that they had deferred their strike (last August) only after an assurance given by the defence ministry and a high-level official committee was constituted to study the possibility of OFB achieving Rs. 30,000 crore production target in the present setup.

"Since there was a dispute between the employees’ federations and government with regard to the terms of reference represented to the defence minister in October 2019, government has arbitrarily made the announcements on corporatisation of OFB by taking advantage of COVID-19 lockdown," joint statement by the defence employees’ federations alleged.

The federations also stated that the government decision has hurt the sentiments of 82,000 employees of ordnance factories who are working relentlessly in manufacturing of all types of PPEs required for medical fraternity for fighting against the COVID-19 pandemic.

"All these ordnance factories’ employees took risk of their life and were working throughout the COVID lockdown. Instead of recognising their service, a major decision [was taken] to convert this war industry as a PSU and thereafter to privatise the same," the statement further said.

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Two books from NeoBioMed

https://www.neobiomed.com/about.html

Biodetectors in Defence, Equipment & Accessories

https://www.neobiomed.com/Brochure_Final_Bio.pdf

Chemical Detectors in Defence, Equipment & Accessories

https://www.neobiomed.com/Chemical_Dete ... ochure.pdf

https://www.neobiomed.com/about.html

Biodetectors in Defence, Equipment & Accessories

https://www.neobiomed.com/Brochure_Final_Bio.pdf

Chemical Detectors in Defence, Equipment & Accessories

https://www.neobiomed.com/Chemical_Dete ... ochure.pdf

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Recently updated

INDIGENISATION REQUIREMENTS OF IAF-PART II

https://indianairforce.nic.in/content/i ... af-part-ii

https://indianairforce.nic.in/sites/def ... t%20II.pdf

INDIGENISATION REQUIREMENTS OF IAF-PART II

https://indianairforce.nic.in/content/i ... af-part-ii

https://indianairforce.nic.in/sites/def ... t%20II.pdf

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Thanks. IAF Materials management has to think this through.jaysimha wrote:Recently updated

INDIGENISATION REQUIREMENTS OF IAF-PART II

https://indianairforce.nic.in/content/i ... af-part-ii

https://indianairforce.nic.in/sites/def ... t%20II.pdf

The quantities are so small who will bid to make such small lots?

They need to make multiple years of procurement and make it attractive for the suppliers.

These small lots are designed to attract imports only as local mfg can't set up facilities or production run.

Management theory shows there is Economic Order Quantity (EOQ) that is a minimum to break even.

These lot sizes are much less than that.

And they need to come up with a material specification for things like Linen and drawings for the manufactured parts to lockdown control.

Is the supplier expected to create drawings of those parts?

Anyway, what's the total price of all those items on an annual basis?

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Can anyone give me some gyaan on what corporatization of OFB means?

My understanding of corporate is that it is a legal entity that has share holders, listed on stock market, etc. Is that what's going on here or something else.

My understanding of corporate is that it is a legal entity that has share holders, listed on stock market, etc. Is that what's going on here or something else.

Re: India's R&D in Defence DRDO, PSUs and Private Sector

These numbers are indeed too small. Some of the parts are such that you could probably farm them out to a local workshop and have them done within a few days. Honestly don't know what they are thinking here.ramana wrote:Thanks. IAF Materials management has to think this through.jaysimha wrote:Recently updated

INDIGENISATION REQUIREMENTS OF IAF-PART II

https://indianairforce.nic.in/content/i ... af-part-ii

https://indianairforce.nic.in/sites/def ... t%20II.pdf

The quantities are so small who will bid to make such small lots?

They need to make multiple years of procurement and make it attractive for the suppliers.

These small lots are designed to attract imports only as local mfg can't set up facilities or production run.

Management theory shows there is Economic Order Quantity (EOQ) that is a minimum to break even.

These lot sizes are much less than that.

And they need to come up with a material specification for things like Linen and drawings for the manufactured parts to lockdown control.

Is the supplier expected to create drawings of those parts?

Anyway, what's the total price of all those items on an annual basis?

Re: India's R&D in Defence DRDO, PSUs and Private Sector

They don't have skin in the game. Just going thru motions and can claim local industry did no respond when parliament question comes up.

Re: India's R&D in Defence DRDO, PSUs and Private Sector

One approach for such small quantities is to have a number of pre-approved suppliers who can bid and make them as required. For example, a number of casting and machine shops that are already pre-approved for capacity, quality, workforce competence can bid for the work packages.

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Please read every word:Lt. Gen..Ravi Shankar(R)

https://www.gunnersshot.com/2020/06/atm ... t.html?m=1

https://www.gunnersshot.com/2020/06/atm ... t.html?m=1

Re: India's R&D in Defence DRDO, PSUs and Private Sector

National Conference on Failure Analysis from 9-11 July, 2020

http://sfaindia.org/cns.html

http://sfaindia.org/NCFA2020.pdf

http://sfaindia.org/cns.html

http://sfaindia.org/NCFA2020.pdf

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Defence reforms are a dream come true, says Baba Kalyani of Bharat Forge

==> Currently working on air defense systems.

==> BK says his biggest (personal) dream is domestic jet engine which can power next generation fighters. He thinks that a consortium of 6-7 companies can pull it off in next 7 years

==> Currently working on air defense systems.

==> BK says his biggest (personal) dream is domestic jet engine which can power next generation fighters. He thinks that a consortium of 6-7 companies can pull it off in next 7 years

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Actually it is a good idea. DRDO could tie up with 6-7 Indian companies, who can finance the completion of Kaveri. In return they get to produce parts for Kaveri and part of IP.Vamsee wrote:Defence reforms are a dream come true, says Baba Kalyani of Bharat Forge

==> Currently working on air defense systems.

==> BK says his biggest (personal) dream is domestic jet engine which can power next generation fighters. He thinks that a consortium of 6-7 companies can pull it off in next 7 years

GoI could put around 200M, the remaining companies 100M each. You get around 900M. They good buy engine test platform and pitch in with material skills.

Re: India's R&D in Defence DRDO, PSUs and Private Sector

I think this is how it happens. Every year a selected list of small components are identified for indigenisation. It does appear this year it is more elaborate though I would like better prepared documents. Poor quality at this level shows to me poor intent.ramana wrote:One approach for such small quantities is to have a number of pre-approved suppliers who can bid and make them as required. For example, a number of casting and machine shops that are already pre-approved for capacity, quality, workforce competence can bid for the work packages.

Re: India's R&D in Defence DRDO, PSUs and Private Sector

MoD should create and fund competition between GTRE/DRDO/HAL on one side and a private industry consortium led by Indian Cos, with foreign collaboration allowed on the other.

Create a temporary agency (chaired by RM and including IAF and IN teams) that will monitor and guide both teams, provide expertise, access to required facilities etc.

IP rights for developed technologies & products will remain (wholly or in part) with each respective team.

Winner gets the prize of delivering 300 engines over the next 10 years.

Somewhat like the F-22 and YF-23 competition.

Create a temporary agency (chaired by RM and including IAF and IN teams) that will monitor and guide both teams, provide expertise, access to required facilities etc.

IP rights for developed technologies & products will remain (wholly or in part) with each respective team.

Winner gets the prize of delivering 300 engines over the next 10 years.

Somewhat like the F-22 and YF-23 competition.

Re: India's R&D in Defence DRDO, PSUs and Private Sector

sir, just as a coffee table discussion can we Identify the such 6-7 companies best suitable for this Jet Engine manufacturing consortium ???nam wrote:Actually it is a good idea. DRDO could tie up with 6-7 Indian companies, who can finance the completion of Kaveri. In return they get to produce parts for Kaveri and part of IP.Vamsee wrote:Defence reforms are a dream come true, says Baba Kalyani of Bharat Forge

==> Currently working on air defense systems.

==> BK says his biggest (personal) dream is domestic jet engine which can power next generation fighters. He thinks that a consortium of 6-7 companies can pull it off in next 7 years

GoI could put around 200M, the remaining companies 100M each. You get around 900M. They good buy engine test platform and pitch in with material skills.

I'm sharing my understanding, gurus here may add/ correct further..........

1. Bharat Forge :- For obvious reasons i.e Indian power house of forging and metallurgical know how.

2. L&T :- Another power house of Indian manufacturing. i think they can contribute.

3. Midhani :- Most of the critical alloy manufacturing tech is with them.

4. BHEL :- Have a 6 decade long experience of manufacturing Boiler & Turbine & other high pressure temperature parts.

5. TATA Steel :- They acquired UK based steel manufacturer Corus in the year 2006, Corus had a respectable number of patents for naval grade steel and other niche steel alloys. Not sure if those IPs are transferable to Tata Steel or not neither I'm sure if those capabilities are fit for Jet Engine Engine tech consortium still though......

6. HAL :- I think after manufacturing Sukhoi engines in house they now have considerable know how in the field.

7. Godrej Aerospace (Godrej & Boyce) :- Have respectable know how on aerospace grade component manufacturing due to long association with ISRO.

8. Brahmos Aerospace:- May be ???

Re: India's R&D in Defence DRDO, PSUs and Private Sector

I don't know where the best place for this is, so mods please move if you deem it appropriate.

Everyone on this board - me included - gets (justifiably) upset every time someone in the armed forces loses their life. Our humanity moves us at the loss of life and we end up raging, ranting, and introspecting. As mostly a lurker, I have seen this cycle repeat itself many times, and we have discussed the same issues to death. It's clear that there are major administrative hurdles blocking progress on defense modernization, indigenization, procurement, research, the use of force (as in the latest clash with china), etc.

I think its time that the people in the administration - MOD, DRDO, OFB, etc. - be forced to confront their humanity when soldiers, pilots, and sailors have lost their lives. They should be made to feel what their politics and bureaucracy causes - the loss of a husband, a father, a son, a friend. The heads of these OFB unions, HAL managers, babus, etc. should be made to go and explain to the families and children of servicemen who have lost their lives WHY their family has been ripped apart. They should be made to do this EVERY TIME so that it is drilled into their head that their work is more than their little silo and world and has a major impact on peoples lives and that of the nation. They should also be made to have multi-day 'trips' and 'workshops' in forward areas so they know what it is like to live in the front lines and feel the pressures of it.

Maybe then there will be progress. Sorry for the rant, I am just tired of seeing so many deaths on our side and so much business as usual in the usual quarters.

Everyone on this board - me included - gets (justifiably) upset every time someone in the armed forces loses their life. Our humanity moves us at the loss of life and we end up raging, ranting, and introspecting. As mostly a lurker, I have seen this cycle repeat itself many times, and we have discussed the same issues to death. It's clear that there are major administrative hurdles blocking progress on defense modernization, indigenization, procurement, research, the use of force (as in the latest clash with china), etc.

I think its time that the people in the administration - MOD, DRDO, OFB, etc. - be forced to confront their humanity when soldiers, pilots, and sailors have lost their lives. They should be made to feel what their politics and bureaucracy causes - the loss of a husband, a father, a son, a friend. The heads of these OFB unions, HAL managers, babus, etc. should be made to go and explain to the families and children of servicemen who have lost their lives WHY their family has been ripped apart. They should be made to do this EVERY TIME so that it is drilled into their head that their work is more than their little silo and world and has a major impact on peoples lives and that of the nation. They should also be made to have multi-day 'trips' and 'workshops' in forward areas so they know what it is like to live in the front lines and feel the pressures of it.

Maybe then there will be progress. Sorry for the rant, I am just tired of seeing so many deaths on our side and so much business as usual in the usual quarters.

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Are you advocating "beatings will continue till morale improves" strategy ?

Sorry, what wrong did the DRDO do or the HAL managers ? They also serve the country, no ? Don't generalize.

Honestly, I think they have contributed much more to our security than I (and most of us in this forum) have.

Sorry, what wrong did the DRDO do or the HAL managers ? They also serve the country, no ? Don't generalize.

Honestly, I think they have contributed much more to our security than I (and most of us in this forum) have.

Re: India's R&D in Defence DRDO, PSUs and Private Sector

No, its not about beatings, its about perspective. I do not disagree with you that they have contributed more than most, but it seems like there are significant administrative hurdles to getting anything implemented. We see frustration everywhere, but there seems to be more of the same 'chalta hai' attitude when it comes to clearances, procurement, etc. I think it would be good to remind these people very visibly what the 'chalta hai' attitude when it comes to administrative work does to the nation's security and the people who fight for it. I don't think its any one person or institutions fault (thus I am not sure this I the right thread for this). I just think there needs to be a significant mindset change, in everyone from the OFB union to the babus in the MOD.

Re: India's R&D in Defence DRDO, PSUs and Private Sector

IIT-Madras and General Electric tie-up to build a next-gen combustor for small aircraft and helicopter engines

By Dia Rekhi, ET Bureau|Last Updated: Jun 19, 2020, 11.23 AM IST

Chennai: IIT Madras and General Electric India Technology Centre (GEITC) are jointly developing a 3D printed combustor aimed at reducing weight and improving fuel efficiency in small aircraft and helicopter engines.

Both organisations are designing the combustor - the burner in a gas turbine engine, with nearly one-tenth of the parts as compared to traditional engines.

The Rs 7.24 crore Uchhatar Avishkar Yojana (UAY) project is being carried out by the aerospace department at the Institute and is being funded by the government of India (75%) and GEITC (25%).

"The fabricated combustor has only four parts whereas the same combustor, with conventional manufacturing, will have at least thirty parts," said Prof SR Chakravarthy, Faculty In-charge, National Centre for Combustion Research - NCCRD at IIT Madras.

"The primary objective of this project is to reduce the length of the combustor, which will reduce its weight. It also reduces the fuel consumption of the engine," he said.

The engine could also be used in power generation. In larger aircraft, it could be used as part of an auxiliary power unit (APU), as well as for distributed/decentralised power generation as in backup gensets, or in remote locations, or along with hybrid solar/wind smart grid solutions.

While there have been several improved combustors designs recently, this project aims to further improve these metrics with a design that uses additive manufacturing technology and non-intrusive laser diagnostics.

The project team has successfully completed testing three 8-cup full annular combustor configurations. The results show the feasibility of 30% reduction in length of a conventional rich burn combustor. Currently, the team is focussing on the optical diagnostics experiments where laser diagnostics tools are being used to understand the flow physics inside the combustor. These results will help optimize the performance and to probe any further possibilities of length reduction, the professor said.

The size and weight of the engine would be the same depending upon how the combustor is designed to fit into the rest of the engine. The weight savings, however, will be on the raw material of fabrication in additive manufacturing. This could lead to a substantial drop in weight, as much as 50% when compared to conventional combustors.

Further, Dr Chakravarthy said the additive manufacturing of the combustors which were tested for this project were outsourced to Indian suppliers. These suppliers, he said, were now capable of adapting additive techniques for geometries as complex as combustor domes and liner, which in turn would help in developing the country’s additive manufacturing infrastructure.

A special feature of this project is that it marks the first time that a 3D printed full annular combustor was tested at actual turbine conditions in India. The lab, which is housed in the National Centre for Combustion Research and Development (NCCRD) at IIT-M also boasts of being the first in India to have a high pressure optically accessible combustor test rig and state of the art laser diagnostics tools under one roof.

IIT-M has an IP rights share with GEITC and expects GEITC to immediately use this in their product. Going forward, Dr Chakravarthy said that if GEITC is not absorbing the technology, for whatever reason, they have the first right of refusal after a lock-in period for IIT-M to commercialise the IP. Commercialization will be in the form of licensing to similar such engine houses as GEITC or to a start-up to develop a product that could be incubated by IIT-M itself.

https://economictimes.indiatimes.com/in ... content=23

By Dia Rekhi, ET Bureau|Last Updated: Jun 19, 2020, 11.23 AM IST

Chennai: IIT Madras and General Electric India Technology Centre (GEITC) are jointly developing a 3D printed combustor aimed at reducing weight and improving fuel efficiency in small aircraft and helicopter engines.

Both organisations are designing the combustor - the burner in a gas turbine engine, with nearly one-tenth of the parts as compared to traditional engines.

The Rs 7.24 crore Uchhatar Avishkar Yojana (UAY) project is being carried out by the aerospace department at the Institute and is being funded by the government of India (75%) and GEITC (25%).

"The fabricated combustor has only four parts whereas the same combustor, with conventional manufacturing, will have at least thirty parts," said Prof SR Chakravarthy, Faculty In-charge, National Centre for Combustion Research - NCCRD at IIT Madras.

"The primary objective of this project is to reduce the length of the combustor, which will reduce its weight. It also reduces the fuel consumption of the engine," he said.

The engine could also be used in power generation. In larger aircraft, it could be used as part of an auxiliary power unit (APU), as well as for distributed/decentralised power generation as in backup gensets, or in remote locations, or along with hybrid solar/wind smart grid solutions.

While there have been several improved combustors designs recently, this project aims to further improve these metrics with a design that uses additive manufacturing technology and non-intrusive laser diagnostics.

The project team has successfully completed testing three 8-cup full annular combustor configurations. The results show the feasibility of 30% reduction in length of a conventional rich burn combustor. Currently, the team is focussing on the optical diagnostics experiments where laser diagnostics tools are being used to understand the flow physics inside the combustor. These results will help optimize the performance and to probe any further possibilities of length reduction, the professor said.

The size and weight of the engine would be the same depending upon how the combustor is designed to fit into the rest of the engine. The weight savings, however, will be on the raw material of fabrication in additive manufacturing. This could lead to a substantial drop in weight, as much as 50% when compared to conventional combustors.

Further, Dr Chakravarthy said the additive manufacturing of the combustors which were tested for this project were outsourced to Indian suppliers. These suppliers, he said, were now capable of adapting additive techniques for geometries as complex as combustor domes and liner, which in turn would help in developing the country’s additive manufacturing infrastructure.

A special feature of this project is that it marks the first time that a 3D printed full annular combustor was tested at actual turbine conditions in India. The lab, which is housed in the National Centre for Combustion Research and Development (NCCRD) at IIT-M also boasts of being the first in India to have a high pressure optically accessible combustor test rig and state of the art laser diagnostics tools under one roof.

IIT-M has an IP rights share with GEITC and expects GEITC to immediately use this in their product. Going forward, Dr Chakravarthy said that if GEITC is not absorbing the technology, for whatever reason, they have the first right of refusal after a lock-in period for IIT-M to commercialise the IP. Commercialization will be in the form of licensing to similar such engine houses as GEITC or to a start-up to develop a product that could be incubated by IIT-M itself.

https://economictimes.indiatimes.com/in ... content=23

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Click on the link below and read this tweet....

https://twitter.com/Maverick_bharat/sta ... 1511667712

https://twitter.com/Maverick_bharat/sta ... 1511667712

Re: India's R&D in Defence DRDO, PSUs and Private Sector

Not just officers and babus but netas also should face inquiry and charges of sedition.Rakesh wrote:Click on the link below and read this tweet....