Tanaji wrote:If an item conforms to designed tolerances, by definition it is standardized. There are no ifs or buts to it, and should be re-usable across planes.

Can you share any references that for Tejas, all items "conforms to designed tolerances" and "re-usable across planes"?

Be specific in your answer. You are making a generic statement "If an item conforms to designed tolerances, by definition it is standardized"

Please answer specifically if in the case of Tejas IOC & FOC birds,

ALL items conforms to designed tolerances and standardized"

And conformity to designed tolerances can be there in parts built to different standards and specifications.

In the pipes and panels in SP-3 and SP-4 not conforming to ICY, they will be conform to design tolerances. Only they will not be standardized and interchangeable.

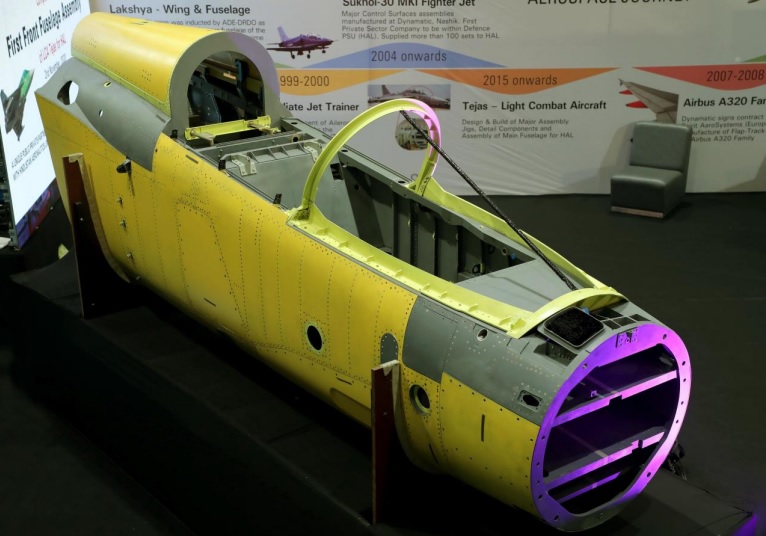

On Tejas, despite FOC SOP and Release to Service Documents certified by CEMILAC, both tooling and building parts to specifications is in work in progress and initial IOC and FOC birds are following earlier build specifications. This is what the Dynamatic twitter and interview of HAL personnel indicate.

Tanaji wrote:The Matrubhumi article is very poorly written

The quotations are verbatim from Sridharan and HAL officials. So instead of shooting the messenger (Murali Anantha Krishnan), please try to understand what Sridharan and HAL officials are saying.

Tanaji wrote:the author does not specify what ICY stands for.

HAL very clearly does.

https://english.mathrubhumi.com/news/in ... -1.1373414

The SP-3 comes with more value additions with around 340 pipelines and 50 panels now achieving ICY or interchangeability standards. (ICY ensures quick replacement of a component without any design changes affecting operational performance.) “In the next aircraft, around 100 panels and 700-plus pipelines will be in the ICY standards,” says an official

It very clearly states the number of panels and pipes that are not standardized (in SP-3), and the further standardization in SP-4 and SP-7.

Tanaji wrote:The whole concept makes no sense to me.

My friend, if you fail to see the numbers provided by HAL and not Murali Anantha Krishnan or me, then what can we do?

Tanaji wrote:Mk 1A will have changes to plumbing and other changes to components. So if your hypothesis was true, the earlier ICY conformance (if one exists) is no longer valid.

Exactly. Which is why it will have a different designation Mk1A altogether.

MWF/Air Force Mk2 will have its own ICY standards

AMCA will have its own ICY standards.

TEDBF/Navy Mk2 will have its own ICY standards

During mid life refits, there will be an option of upgrading the Mk1 IOC and Mk 1 FOC to Mk1A.

We also planned to upgrade the 18 original Su-30K to Su-30MKI Phase 4 standards but given their wear and tear due to high hours of flying for training & post Kargil operations and Op Parakram, we decided to return them and ordered 18 fresh Su-30MKI replacements from Russia in 2007.

Even the remaining 32 Su-30MKI (SB019 - SB050) were not in the Su-30MKI Phase 4 standards and should have been retrofitted/being retrofitted.

This website gives the correct details of the various standards within Su-30MKI

http://sukhoi.mariwoj.pl/su-30-in.htm

1) Contract 11.1996 for 40 x Su-30MKI; 12.1998 extended to 50 x Su-30MKI

Su-30K:

- 1st batch 03-06.1997: 8 x Su-30MKI-I (=Su-30K) [SB001...SB008]

- 2st batch 1999: 10 x Su-30MKI-II (=Su-30K upgraded with french SAGEM avionics) [SB009...SB018] (tsarkar note: these were an Indonesian order that they couldnt pay due to 1997 Asian financial crisis

https://en.wikipedia.org/wiki/1997_Asia ... ial_crisis)

=========================

TOTAL: 18 Su-30MKI-I and MKI-II (=Su-30K).

Su-30MKI:

3rd batch 2002: 10 x Su-30MKI-III (=Su-30MKI) [SB019...SB028]

4th batch 2003: 12 x Su-30MKI-III (=Su-30MKI) [SB029...SB040]

5th batch 2004: 10 x Su-30MKI-III (=Su-30MKI) [SB041...SB050]

6th batch 2005: 16 x Su-30MKI-III (=Su-30MKI) [SB051...SB066]

48 aircrafts + 2 to prepare first Indian licensed Su-30MKI in 2004

Total: 50

2) Contract 12.2000 for 140 x Su-30MKI on licence production; realised in HAL since 2004.

3) Contract 2007 for 40 x Su-30MKI on licence production; realised in HAL.

4) Contract 12.2011 for 42 x Su-30MKI on licence production integrated with Brahmos missile, Irbis radar; realised in HAL.

=========================

TOTAL: 272 Su-30MKI, incl. 50 from Russia and 222 licensed production in HAL, excluding 18 Su-30K.

He got the marks wrong but the tail numbers and timeline is accurate. Correcting the marks -

1st batch 03-06.1997: 8 x Su-30K-I [SB001...SB008] (K not MKI)

2st batch 1999: 10 x Su-30K-II [SB009...SB018] (K not MKI, Indonesian order)

3rd batch 2002: 10 x Su-30MKI-I [SB019...SB028](I not III)

4th batch 2003: 12 x Su-30MKI-II [SB029...SB040] (II not III)

5th batch 2004: 10 x Su-30MKI-III [SB041...SB050] (Correctly mentions III)

6th batch 2005: 16 x Su-30MKI-IV [SB051...SB066] (IV not III) (These are replacements of the original 18K)

Rest following these are IV aircraft. There were news reports in late 90's & early 2000's that are no longer available now. But Kapil's report from 2002 is there on BR.

I'm not sure if the last 42 strengthed airframes for BrahMos are IV or have a new standard

I'm also not sure which standard the next 12 will be.

Is this so difficult to understand?

And no, its not a negative comment on Tejas since even the Su-30MKI and every other aircraft development program goes through this.

So requesting posters to be realistic and start seeing the different shades of grey (Phase I - IV) or IOC, FOC, Mk1A, or ICY of SP3, 4 & 7 that HAL officials have stated instead of writing things perfect in theory but not reflected in reality.