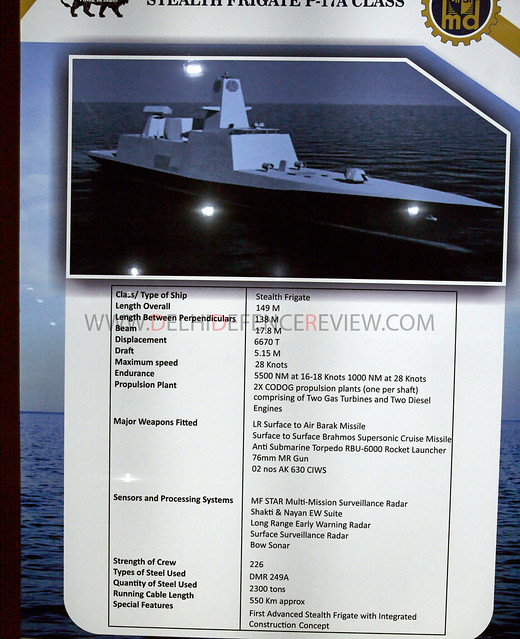

MDL Stealth Frigate P-17A Class Info by Delhi defence Review, on Flickr

quite clean layout ! .. now if they replace that smallish oto melara with this

I highly doubt P -17a will resemble the CGI image, the model is more accurate representation.kit wrote:quite clean layout ! .. now if they replace that smallish oto melara with this

maz wrote:The P17A model and the image in the GRSE future projects poster clearly shows that the RCS of the actual design appears lower than the earlier renderings. One industry source thinks it has to do with operational feedback from from the IN regarding the enclosed boat hangars on the P17 Shivalika. The translation is that the the boat handlers are having difficulty in operating the ships' boats from the hangars. This is really a pity because most contemporary design have enclosed boat hangars and having exposed boat davits cannot be good for the RCS unless some magic has been done elsewhere to compensate.

It would be nice to get the viewpoints of the naval veterans on BR. TSarkar, Chetak, et. al. where art thou?

As for the ASW SWC, logically both yards should build a common design but it is unclear if GRSE will agree to build the CSL's design. If two designs are built, then the whole idea of standardizing goes out the window.....

TheIndonesian Navy - Angkatan Laut - has a similar problem. They are building 42 x 40m-45m patrol boats - supposedly to a common design from 3 or 4 shipyards. They tried and failed to get the builders to work to a common design. Two built near identical designs with internal differences and the other one to two yards have a rather different external appearance.

My 2 cents: the IN should make this sort of thing very clear from the outset. i.e. shipsyards in a multi-yard program like that of the ASW SWC have to build to the winning shipyards design or to a common design with the best features of both designs that would be determined by the DND. The downside of this approach is the added time to refine the design. But it is doable if there is a clear timeline goal - say +6 months - and strong project management to ensure adherence to schedules and prevent scope creep and suchlike.

again curious to know what people think.

The challenge is to insure that the blue prints are not deviated from. That requires the navy to take ownership of the construction process regadless of which yard is building the ship. Internal fittings can be different from ship to ship. But the design once frozen, will be unchanged from yard to yard.kit wrote:maz wrote:The P17A model and the image in the GRSE future projects poster clearly shows that the RCS of the actual design appears lower than the earlier renderings.

As for the ASW SWC, logically both yards should build a common design but it is unclear if GRSE will agree to build the CSL's design. If two designs are built, then the whole idea of standardizing goes out the window.....

again curious to know what people think.

The modular construction works perfectly well for mass production .. witness china producing different classes at same time in different yards, how can it happen that one yard can make a ship of same class differently than the other ? same blueprints ?.. dont they use the same suppliers for components

Whoa. That Indonesian example. That’s completely insane!!! As someone in the business community, there is no way a company sourcing a product would ever allow that — let alone a nation state. You would take away contracts from manufacturers/yards that can’t produce to the design agreed upon.maz wrote:The P17A model and the image in the GRSE future projects poster clearly shows that the RCS of the actual design appears lower than the earlier renderings. One industry source thinks it has to do with operational feedback from from the IN regarding the enclosed boat hangars on the P17 Shivalika. The translation is that the the boat handlers are having difficulty in operating the ships' boats from the hangars. This is really a pity because most contemporary design have enclosed boat hangars and having exposed boat davits cannot be good for the RCS unless some magic has been done elsewhere to compensate.

It would be nice to get the viewpoints of the naval veterans on BR. TSarkar, Chetak, et. al. where art thou?

As for the ASW SWC, logically both yards should build a common design but it is unclear if GRSE will agree to build the CSL's design. If two designs are built, then the whole idea of standardizing goes out the window.....

TheIndonesian Navy - Angkatan Laut - has a similar problem. They are building 42 x 40m-45m patrol boats - supposedly to a common design from 3 or 4 shipyards. They tried and failed to get the builders to work to a common design. Two built near identical designs with internal differences and the other one to two yards have a rather different external appearance.

My 2 cents: the IN should make this sort of thing very clear from the outset. i.e. shipsyards in a multi-yard program like that of the ASW SWC have to build to the winning shipyards design or to a common design with the best features of both designs that would be determined by the DND. The downside of this approach is the added time to refine the design. But it is doable if there is a clear timeline goal - say +6 months - and strong project management to ensure adherence to schedules and prevent scope creep and suchlike.

again curious to know what people think.

any Idea for which ships?BREAKING: India clears $470 million deal for 13 @BAESystemsInc Mk45 naval main guns for under-build @IndianNavy warships.

Livefist Verified account @livefist

1m1 minute ago

More

For those asking, the 13 Mk.45 guns are for:

* 4 x Project 15B (Visakhapatnam class) destroyers

* 7 x Project 17A stealth frigates

* 2 x INS Dronacharya & INS Valsura training schools

Should not be that big of a redesign since below deck requirements for mk.45 aren't much different from oto 127/64. That said latter more capable it's shame politics once again impending progress.sahay wrote:The fallout from Augusta Westland scam was blocking the contract for Oto Melara 127 mm. I guess this is the resolution for that conundrum. I would expect some delays in announced timelines for P15B and maybe even P17A, now that they have to be redesigned to accommodate a different gun.

P15A from what I understand was delayed mainly due to steel, SY delays and Barak-8 being delayed. Also Ak-100 is significantly bigger than oto 76mm, so it's not that same as current situation where as we are taking gun systems that are quite similar in size.sahay wrote:I wouldn't be too sure of that. According to a CAG report, the late switch from AK-100 to 76 mm SRGM caused significant delays during P15A construction. That switch was made after one ship was launched, but now we have two hulls in the water that need to be modified for Mk 45.

IS this the gun ?Kakarat wrote:https://twitter.com/livefist/status/989858896910176257any Idea for which ships?BREAKING: India clears $470 million deal for 13 @BAESystemsInc Mk45 naval main guns for under-build @IndianNavy warships.

aren't the Navy getting Otobreda 127/64

Kakarat wrote:https://twitter.com/livefist/status/989858896910176257any Idea for which ships?BREAKING: India clears $470 million deal for 13 @BAESystemsInc Mk45 naval main guns for under-build @IndianNavy warships.

aren't the Navy getting Otobreda 127/64

From Economic Times:Meanwhile, the DAC also approved the procurement of thirteen 127 mm calibre guns for the Navy, the ministry said. "These guns will be fitted on-board new construction ships for undertaking surface engagements including Naval Gunfire Support Operations. The guns will enable Naval ships to provide fire support and engagement of targets on the land," the ministry said.

These guns have engagement range of 24 kilometres, which could be extended further by using Extended Range Gun Munitions.

andThe Central Scientific Instruments Organisation (CSIO) here has joined hands with a Mumbai based firm for the indigenous development of night-vision goggles compatible Helicopter Visual Landing aid System (HVLAS) for maritime operations.

This equipment guides a helicopter for safe landing on the flight deck of a ship at sea. It comprises optical references and lights for directing the helicopter and also predicts the optimum future moment for safe touchdown on the deck.

A memorandum of understanding in this regard was signed by the CSIO with Elcome Integrated Systems Private Limited

HVLAS will be the first-ever indigenous equipment of its kind that will improve the operational capability of Indian warships. The immediate target for such a solution is the current project for seven stealth frigates of the P-17A class being built by Mazagon Docks Limited for the Navy.

The problem is that the PSU yards don't follow legitimate costing systems that are on par with what the pvt yards do and quote ridiculous amounts that the private yards can't compete with. Since they work for the MOD the costs get adjusted elsewhere and escalations are handled out of the govt's money, so in the end the cost to the nation ends up being higher than if it would have been built by a pvt yard, but yes they bid pretty low.Pratyush wrote:I don't think that nomination of PSU yard's by mod will be a problem. As long as the MOD can say that the L1 Pvt yard will work on the prices quoted by PSU yard.

This is the most common process followed for central government tenders. That being the case it can be executed for mod tenders as well.

However, in this scenario, the biggest challenge will be small order quantity to justify splitting up of the orders.

Ideally the boats should have been moved to stern ramps with enclosed covers like US coast guard designs. The stern should have additional ramps for towed array sonars, towed torpedo decoys, towed array sonar for mareech etc. However our designers are very conservative. Also launching of boats is required for anti terrorist / anti piracy / HADR secondary missions while the primary mission of these ships is anti air / ship / surface / land attack. Ideally secondary criteria shouldn't cloud primary requirements but sadly we're doing more of secondary stuff than primary most of the time.maz wrote:The P17A model and the image in the GRSE future projects poster clearly shows that the RCS of the actual design appears lower than the earlier renderings. One industry source thinks it has to do with operational feedback from from the IN regarding the enclosed boat hangars on the P17 Shivalika. The translation is that the the boat handlers are having difficulty in operating the ships' boats from the hangars. This is really a pity because most contemporary design have enclosed boat hangars and having exposed boat davits cannot be good for the RCS unless some magic has been done elsewhere to compensate.

It would be nice to get the viewpoints of the naval veterans on BR. TSarkar, Chetak, et. al. where art thou?

Impossible in the Indian context. Indian shipyards modernise and purchase different equipment at different points of time and there is no standardisation of equipment, processes or training of shipwrights and fitters between yards. Employees at MOD yards are civilians. Which is why IN/ICG FAC built at GSL, CSL, HSL or GRSE for same role with same engine (MTU) or armament (Medak gun) differ in design or layout.maz wrote:As for the ASW SWC, logically both yards should build a common design but it is unclear if GRSE will agree to build the CSL's design. If two designs are built, then the whole idea of standardizing goes out the window.....

TheIndonesian Navy - Angkatan Laut - has a similar problem. They are building 42 x 40m-45m patrol boats - supposedly to a common design from 3 or 4 shipyards. They tried and failed to get the builders to work to a common design. Two built near identical designs with internal differences and the other one to two yards have a rather different external appearance.

My 2 cents: the IN should make this sort of thing very clear from the outset. i.e. shipsyards in a multi-yard program like that of the ASW SWC have to build to the winning shipyards design or to a common design with the best features of both designs that would be determined by the DND. The downside of this approach is the added time to refine the design. But it is doable if there is a clear timeline goal - say +6 months - and strong project management to ensure adherence to schedules and prevent scope creep and suchlike.

again curious to know what people think.

Yes, but we're very far from there. For starters all Govt shipyards could start with a common training program for shipwrights, fitters, welders, electricians during induction. This will result in basic commonality.maz wrote:TSarkar, thank you for your insights. While full standardization does not appear to be feasible, perhaps there's a lot to be learnt from Damen's model of using modular hull sections to rapidly construct variants of a base design as in the SIGMA concept?

Plus unaffected by rolling motion of ship that during davit launch bangs boat and crew against the hull. Stern launch will enable operations in higher sea states. The Helicopter Hanger and rest of superstructure needs to move forward to enclose the space currently occupied by boats and move the boats to stern. Added benefit is a longer flight deck in the stern that can accommodate landing by bigger helicopters. Plus the hanger accommodating helicopters moves closer to ships centre of gravity improving stability.maz wrote:Yes, stern ramps for ships' boats is the way to go isn't it? Way quicker than the manpower intensive and time consuming davit launch or crane launch methods...

PSUs don't include many of the costs and are more likely to get additional payments if there are cost overruns / delays. If there was similar behaviour by private yards then later on 'corruption' investigation will ruin the yard and the powers be. Only Ambani bros have the wherewithal of creative accounting to compete in that universe.Pratyush wrote:I don't think that nomination of PSU yard's by mod will be a problem. As long as the MOD can say that the L1 Pvt yard will work on the prices quoted by PSU yard.

This is the most common process followed for central government tenders. That being the case it can be executed for mod tenders as well.

However, in this scenario, the biggest challenge will be small order quantity to justify splitting up of the orders.

Uh i shot all those picturesmaz wrote:Prasad, would you have any contact with the Delhi Defence Review outfit? I need a high rez pix of that GRSE poster. Can you help Sir?

The change of gun mount caused significant delay too. Check this CAG report on page 48:John wrote:P15A from what I understand was delayed mainly due to steel, SY delays and Barak-8 being delayed. Also Ak-100 is significantly bigger than oto 76mm, so it's not that same as current situation where as we are taking gun systems that are quite similar in size.

You may be right that the redesign may not be as large this time, but it is still a different gun with different mounting requirements.Similarly, the changes in the gun mount were decided by Navy in March 2008 after the first ship was launched. This necessitated re-design of the entire structure in and around the gun mount and barbette.

Prasad wrote:Uh i shot all those picturesmaz wrote:Prasad, would you have any contact with the Delhi Defence Review outfit? I need a high rez pix of that GRSE poster. Can you help Sir?I'll see if I have a higher res shot. Don't think there is but will look.

I have come across the P-18 next gen DDG on some of the other fora on the interweb. Some of the defence journalists have also referred to the next gen DDG in news reports. I think MDLs boss also referred to it in one of the Defexpo 2018 show dailies.Aditya G wrote:Maz

Any news of Project-28A and Project-18 DDG? Do these even exist?