A near-invisible silica gel that would serve as a thermal barrier in cryogenic fuel tanks, boot soles and sun films may sound like a magical product straight from a sci-fi.

But it’s a tangible reality that researchers of the Indian Space Research Organization at its Vikram Sarabhai Space Centre (VSSC), Thiruvananthapuram, have made possible.

The yet to be christened product, the hydrophobic silica aero gel as it is known now, is supposed to have low thermal conductivity and density and high specific surface area and can be applied on any surface.

With its “exotic properties,” silica aero gels are attractive candidates for many unique thermal, optical, acoustic, catalytic and chemical applications and are best known for their “super-insulating property.”

Silica aero gels can be made in chunks (granular), beads, powder and tape or sheet form, and may be used as the application demands, according to VSSC.

As air fills the gel up to 95 per cent of its size, it comes as super lightweight material. The air molecules trapped inside the gel would act as insulators, and its heat conductivity is close to zero. They could be used for coating the windows of houses and vehicles as they would let in 95 per cent of the light that falls on the surface and fully deflect the heat.

“The researchers stumbled upon the exotic properties of the gel during their search for a super thermal insulator for the cryogenic fuel tanks of rockets. The temperature on the surface of the rockets is likely to be between 300 and 400 degree Celsius during its flight, and the cryogenic fuel needs to be insulated. Thus, the gel was developed,” explained K. Sivan, director, VSSC.

As the gel acts as a thermal barrier, it could be used as a protective component of clothes and boots of solders stationed in extremely cold regions such as Siachen and Kargil. The weight of military clothes could be brought down to ordinary dresses after applying the gel over it thus giving the much required freedom of movement for the soldiers. To coat a jacket may require around 500 grams of gel. “Discussions are on with some textile developers for the design of cloths by applying gel over it,” said Dr. Sivan.

“Besides apparel for soldiers, the gel could also be used for heavy duty dresses used by researchers working in Arctic/Antarctic expeditions. For insulating cryogenic fuel tanks, 2.8 kg of gel is required. It needs to be produced in large quantities for commercial use and discussions are on with some entrepreneurs,” he explained.

“ISRO has offered the knowhow of the technology to suitable entrepreneurs in India and the benefits from the transfer of technology would go to the country,” he said.

The other applications of the material include acoustic insulations, building and pipeline insulation and window facades as translucent panels which allow natural light but not heat for hot areas where air conditioners are and trapping heat in cold places.

It would also be used for controlling oil spills and vibration. Other applications include acoustic damping materials and insulation in refrigerators, fillers or additives in paints, sealants, adhesives, cement, coatings, foams, and for increasing the heat resistance of the material, according to VSSC sources.

The RLV-TD is unlikely to be recovered from sea during this experiment as it is expected that the vehicle will disintegrate on impact with water since it is not designed to float. The purpose of the experiment is not to see it float but to glide and navigate from a velocity five times higher than the speed of sound onto a designated virtual runway in the Bay of Bengal some 500 km from the coast.

Very similar in its looks to the American space shuttle, the RLV-TD being experimented is a scale model which is almost 6 times smaller than the final version.

K Sivan, director of the Vikram Sarabhai Space Centre, Thiruvananthapuram, says, "These are just the first baby steps towards the big Hanuman leap."

Was always the plan. The recovery part will be the next phase called LEX (Landing EXperiment) where the test article will landon a runway after hypersonic suborbital flight. I believe there was talk of building a long enough runway for this purpose.A Nandy wrote:http://timesofindia.indiatimes.com/home ... 276174.cms

The RLV-TD is unlikely to be recovered from sea during this experiment as it is expected that the vehicle will disintegrate on impact with water since it is not designed to float. The purpose of the experiment is not to see it float but to glide and navigate from a velocity five times higher than the speed of sound onto a designated virtual runway in the Bay of Bengal some 500 km from the coast.

Very similar in its looks to the American space shuttle, the RLV-TD being experimented is a scale model which is almost 6 times smaller than the final version.

K Sivan, director of the Vikram Sarabhai Space Centre, Thiruvananthapuram, says, "These are just the first baby steps towards the big Hanuman leap."

Just some clarifications.Gagan wrote:More Vehicle Assembly buildings seem to be coming up on the new launch pad.

There are already 2 along the main railway transport line, one seems to be perpendicular and another at an angle...

Nice video, though they could have been more clear about the actual demonstrator vehicle being tested next month- the film makes it look like the prototype is going to have a semi- cryogenic engine, and the main section a cryogenic engine. That I'm sure is not what is being flown in June! IIRC, the test vehicle will have a conventional solid booster, and some scramjet in the second stage(?). They do talk about the TD, but only after confusing/misleading stuff about the composition.Austin wrote:ISRO's RLV-TD Reusable Launch Vehicle technology Demonstrator - ISRO making india proud

They havent refurbished and launched any of the 3 returned boosters yet, so we don't really know cost-wise yet. If it does turn out that way, I wonder how long it would take for us to start returning the booster which will launch the RLV itself.There was one news article in ToI that talked about SpaceX beating ISRO in terms of cost advantage once their reusable rockets mature.

So for the next stage of the experiment, the LEX - where could they build this long runway? SHAR?The recovery part will be the next phase called LEX (Landing EXperiment) where the test article will landon a runway after hypersonic suborbital flight. I believe there was talk of building a long enough runway for this purpose.

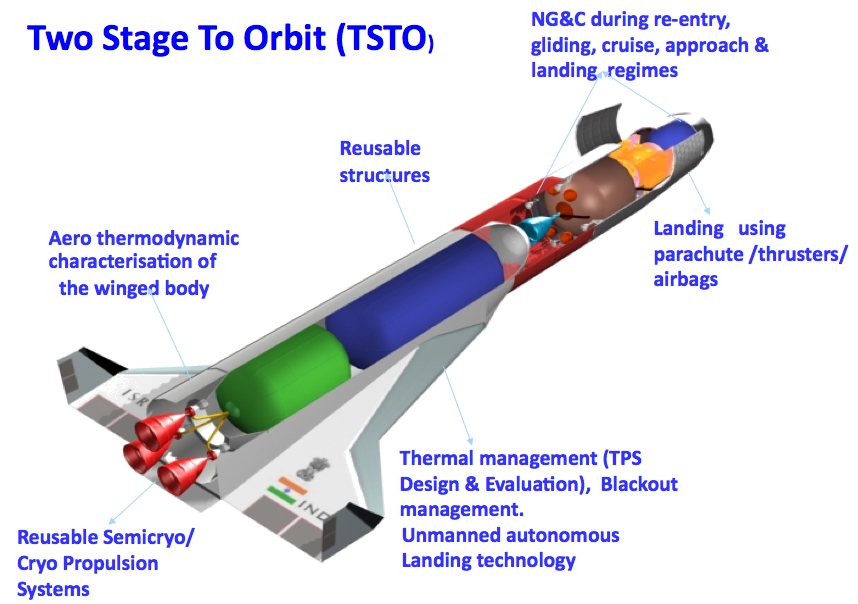

ISROs approach to reusability, as of now, is the RLV TSTO. A 2 staged rocket with lower stage being a semicryogenic flyback booster and the upper stage being retrieved through parachutes. This was (is) their approach. They are also working on air breathing scramjet engines.schinnas wrote:I couldn't find any concrete answers through Google chacha. However it looks like ISRO is doubling down on reusable shuttle option and not reusable rockets like Space X. Is there a plan in the medium future to develop reusable rockets?

It looks to me that a mature space program would need both. Can experts comment on the strategy of ISRO. There was one news article in ToI that talked about SpaceX beating ISRO in terms of cost advantage once their reusable rockets mature.

A Nandy wrote:They havent refurbished and launched any of the 3 returned boosters yet, so we don't really know cost-wise yet. If it does turn out that way, I wonder how long it would take for us to start returning the booster which will launch the RLV itself.There was one news article in ToI that talked about SpaceX beating ISRO in terms of cost advantage once their reusable rockets mature.

That should certainly undercut SpaceX

Provided we have the funding to go through all the steps. SpaceX seems to be building upon a long history of reusability related programmes like

https://en.wikipedia.org/wiki/McDonnell_Douglas_DC-X

So for the next stage of the experiment, the LEX - where could they build this long runway? SHAR?The recovery part will be the next phase called LEX (Landing EXperiment) where the test article will landon a runway after hypersonic suborbital flight. I believe there was talk of building a long enough runway for this purpose.

Cool! so they are planning to retrieve the first stage....with lower stage being a semicryogenic flyback booster

There really needs to be a like button for individual posts!HEX-01 isn't the design profile of RLV-TSTO. In TSTO, reusable part will be the booster which will fly back and land on the runway.

It's not what was handed on a platter. The approach should be to do what is practical i.e. even if only a 1st stage recovery is possible, work on that today and make it happen, rather than build castles in the air about a completely recoverable system. At least that way ISRO can maintain it's price edge and continue to compete with Musk etc.prasannasimha wrote:Let us not forget that Elon Musk and others get preexisting technology handed over to them in a platter from NASA

not exactly......prasannasimha wrote:Let us not forget that Elon Musk and others get preexisting technology handed over to them in a platter from NASA

What payload can it launch into LEO and GEO and at what cost/kg? The reason the US space shuttle was doomed was because of cost considerations. Fuel fraction to LEO and GEO vs revenue loss because of reduced payload vs cost of building new 2nd/1st stage.....disha wrote:

ISRO has been on the RLV-TD/TSTO plan since almost a decade. ISROs RLV/TSTO plan is the *only* viable alternative to reduce cost of space travel.

RLV/TSTO is scalable., the orbiter on top of the reusable flyback booster can be customized to requirements. It can carry a crew or additional cargo (or can be stacked, based on the size and dynamics of the reusable flyback booster).

I do not mind it being called a desi space shuttle as long as it provides a very low cost safe way to go to space.

the present day x-37b is 29 feet long with a wing span of 14 feet and has a cargo bay about 5 x 6 feet big. the US Air Force seems to be very happy with it.ldev wrote:What payload can it launch into LEO and GEO and at what cost/kg? The reason the US space shuttle was doomed was because of cost considerations. Fuel fraction to LEO and GEO vs revenue loss because of reduced payload vs cost of building new 2nd/1st stage.....disha wrote:

ISRO has been on the RLV-TD/TSTO plan since almost a decade. ISROs RLV/TSTO plan is the *only* viable alternative to reduce cost of space travel.

RLV/TSTO is scalable., the orbiter on top of the reusable flyback booster can be customized to requirements. It can carry a crew or additional cargo (or can be stacked, based on the size and dynamics of the reusable flyback booster).

I do not mind it being called a desi space shuttle as long as it provides a very low cost safe way to go to space.

It is just laughable to see an assertion of "not exactly handed to him on a platter".,TSJones wrote:

what he got was the design of the Apollo lunar landing module engine from NASA which is probably in the public domain anyway.

he then blew that engine up into the present day Merlin engine.

he did hire some ex-astronauts and NASA personnel but that is standard industry practice. (mainly for the development of the Dragon space capsule)

he also got the use of a US missile test site in the Kwajalein islands and the use of an old Navy facility at Mcgregor Tx near Fort Hood army base.

Musk manufactures his rockets under a secret process developed by his staff. He will not patent any of his technology for fear that the Chinese will read the patents and reverse engineer it.

not exactly handed to him on a platter.

A request., any further discussion of spacex should be taken off from this thread.Musk has repeatedly said that, without the NASA money, development would have taken longer. SpaceX's statement about the NASA contract was:

SpaceX has only come this far by building upon the incredible achievements of NASA, having NASA as an anchor tenant for launch, and receiving expert advice and mentorship throughout the development process. SpaceX would like to extend a special thanks to the NASA COTS office for their continued support and guidance throughout this process. The COTS program has demonstrated the power of a true private/public partnership and we look forward to the exciting endeavors our team will accomplish in the future.[21]

that's just one example. and that's why it wasn't handed to them on a platter.....their willingness to adopt new techniques that no one else does.Once that decision was made, SpaceX conducted an evaluation of available composites engineering solutions and decided that Siemens PLM (http://www.siemens.com/plm) Software’s Fibersim software was the best fit for its design and manufacturing environment.

SpaceX has used Fibersim to design and manufacture a variety of composite parts on both the Falcon rocket and the Dragon capsule. Fibersim is being used to develop production fiber placement diagrams and laser projection files. It is also used to assist with actual fiber placement for the spacecraft’s thermal protection system, including the heat shield, exterior panels, insulating layers on the rocket and spacecraft, and several panels around the nose cone and engines.

“Fibersim enables us to work in parallel between design and manufacturing, which is very important to us since we’re such a fast-paced organization,” notes Derek Lies, structural designer for composite panels used on the Dragon capsule. “It definitely helped improve the collaboration between design and manufacturing. And we also found that Fibersim very nicely captured the vocabulary of composites and provided an intuitive workflow, which enables our people who aren’t trained in composites to get up and running very quickly.”

They already are:disha wrote:US wants to undercut other agencies - may actually come back and say other nations need to privatize their space programs and not subsidize it.

The FAA assured COMSTAC that the agency’s opinion would be part of the current review of whether India’s refusal to sign a Commercial Space Launch Agreement (CSLA) on rocket pricing still justifies the ban. The review, led by the U.S. Trade Representative, is the reason COMSTAC had raised the issue.

Source: U.S. launch companies lobby to maintain ban on use of Indian rockets - Space NewsThe CSLA, dating from 2005, is the U.S. government’s way of protecting the seemingly forever-nascent U.S. small-satellite launch industry from competing with government-controlled foreign launchers for U.S. business. It seeks to oblige non-U.S. rocket providers to sign a CSLA that, for all intents and purposes, sets U.S. commercial launch prices as the world minimum for government-owned non-U.S. launch providers.

If the cost per kg comes down then the payload capacity is immaterial. RLV-TSTO's aim is to reduce the cost to 1/5th to 1/10th the current cost. You may come and say - how come I can launch a 10-ton sat to GTO? Well., you can launch 10 1-ton modules which will assemble itself in GTO and boost itself into GSO. The cost itself will still be 1/10th.ldev wrote: What payload can it launch into LEO and GEO and at what cost/kg? The reason the US space shuttle was doomed was because of cost considerations. Fuel fraction to LEO and GEO vs revenue loss because of reduced payload vs cost of building new 2nd/1st stage.....

I think the starting point is what is the actual current cost in dollars/rupees per kg to LEO and GEO? Does not matter whether it is one launch of 10 tons or 10 launches of 1 ton. What is ISRO's cost for a PSLV launch per kg currently to LEO? What does Antrix charge its customers? For comparison, SpaceX cost for the Falcon 9 is $62.1 million to lift 22,400 kgs to LEO, that is $2767/kg and that is without any reusability of any stage. Their near term goal is to reduce LEO cost to $1650/kg when their next rocket Falcon Heavy comes online. A reusable first stage only, will reduce prices for each rocket by a further 30% i.e. ~$2000/kg for the Falcon 9 and below $1200/kg for the Heavy.disha wrote:ldev wrote: If the cost per kg comes down then the payload capacity is immaterial. RLV-TSTO's aim is to reduce the cost to 1/5th to 1/10th the current cost. You may come and say - how come I can launch a 10-ton sat to GTO? Well., you can launch 10 1-ton modules which will assemble itself in GTO and boost itself into GSO. The cost itself will still be 1/10th.