Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Graceful moves by Tejas! So effortless.

Kartik saar - in general, when shooting events like these, there needs to be 3-4 cameras (or more) focusing on different subjects and mixing is done from these live feeds. No idea of DD does these....

Kartik saar - in general, when shooting events like these, there needs to be 3-4 cameras (or more) focusing on different subjects and mixing is done from these live feeds. No idea of DD does these....

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

so what was AOA? Instant one and it was able to sustain itself? Any idea how does it compare to its counterpart - Gripen and Blunder?

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

I failed to see how did you conclude from that news that this is the first ICY Front fuselage away of all those have been manufactured till now. This is in all probability the first front fuselage assy that Dynamatic has finished and the certification is limited only to their production as a supplier. So far the Front fuselage is being made by HAL itself and there is no indication that the aircrafts after initial few, did not have ICY until now.tsarkar wrote:This is a very important post for those questioning why IAF isnt ordering Tejas in large numbers or why manufacturing is taking time. The first standardized ICY forward fuselage is delivered only now. The aircraft parts delivered so far were not "completely" standardized and inducting non standardized parts Tejas is a maintenance nightmare in frontline units.Kartik wrote:Video that shows the forward fuselage jig at Dynamatic Technologies' facility in Bangalore. It has delivered the first Tejas forward fuselage module- first article ICY jig clearance.

Twitter link

Video link

Now that ICY is getting achieved, we will see orders and faster rate of manufacture.

Please note, the Tier1 suppliers are not going to completely replace production of these assy. They are only going to add to the capacity that HAL already has. May be in future, when they have achieved stable production, HAL might start offloading their own workshare to these Tier1 suppliers.

Among others, from the news in Public domain that I have seen, only L&T has supplied their assy, wing sets, that were used in actual production. This is the second supplier reaching that milestone. I am not sure what is the status the other two have for mid and rear fuselage.

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Twitter of IR

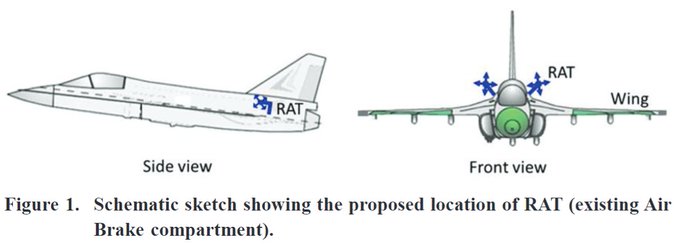

My guess the purpose of RATs is to have a limited control on the jet in case of loss of power due to malfunction or damage in action.Interesting. HAL/ADA considering use of RATs (Ram Air Turbines) instead of airbrakes on LCA. Useful in emergency landing situations.

1:15 AM · Oct 16, 2020

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Because they are making a public announcement about itJayS wrote:I failed to see how did you conclude from that news that this is the first ICY Front fuselage away of all those have been manufactured till now.

Also because that is the caption mentioned in the video https://twitter.com/DynamaticTech/statu ... 2280088577

If HAL did it earlier, then this wouldn't have been "a milestone in our Nation’s Aerospace journey", would it?This is a milestone in our Nation’s Aerospace journey

If HAL would have achieved the said milestone earlier, then they would have made an announcement of achieving a milestone in our Nation's Aerospace journey.

If you do have references that HAL forward fuselages before this one has achieved ICY, please do provide the reference to substantiate your post.JayS wrote:This is in all probability the first front fuselage assy that Dynamatic has finished and the certification is limited only to their production as a supplier. So far the Front fuselage is being made by HAL itself

This was work in progress and the latest update I read was the one below.JayS wrote:there is no indication that the aircrafts after initial few, did not have ICY until now.

https://english.mathrubhumi.com/news/in ... -1.2464308

ICY is an important factor for achieving mass production as well as maintainability in the field by standardizing and having interchangeable tools and parts. Otherwise aircraft will need their parts custom built for repair or replacement.Sridharan, who has been credited with establishing the new LCA Division.....He says the LCA Division developed ICY (interchangeability) tools for all 147 panels and for 830 pipelines out of 934 pipelines within the build of first seven SP Tejas aircraft itself.

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

ICY is NOT about quality as your post implies. ICY is about standardization to enable mass production.Tanaji wrote:Any article that is manufactured by a reasonably competent engineering firm will have tolerances associated with them. These define all aspects of the article, from physical dimensions to material strengths such as the amount of shear stress and other related forces it must withstand. As far as I know, HAL does not have kabadiwalas working for them that hammer sheet metal into aircraft skin panels or people running around with blow torches curing composites. They in most likely will have a reasonably competent QA department (given that they are not OFB), that will or should reject articles manufactured outside the said tolerances. Most likely the parts are being manufactured using multi axis CNC machines that are programmed for repeativity which further ensure tolerances are met. So I am not sure where this inter changeability comes from, or more to the point, I am not grasping some fundamental concept that causes each part to be so different from each other even when meeting its tolerance. Aeronautical tolerances must be even more stricter, than say, automobile tolerances, so margin of error would be even less. Ppeople have remarked that the Tejas skin seems to be like Hema Malini's cheeks, so this is not Marut era design tolerance...

Its nothing to do with Hema Malini or Om Puri's cheeks. Its about how the cheeks are made and maintained.

There are many luxury automobiles that are hand built. Many high end hunting / sniping rifles are hand built. The Munger and Darra Adam Khel AK-47's do their job well.

ICY is an important factor for achieving mass production as well as maintainability in the field by standardizing and having interchangeable tools and parts. Otherwise aircraft will need their parts custom built for repair or replacement.

And since those aircraft are one off, unless refitted, their parts arent stocked but custom made by the factory. This is the reason why initially manufactured aircraft are stationed near the factory. Eg. Sulur near Bangalore. They may make occasional deployments to forward bases but stay close to the factory for ease of maintenance.

Ofcourse during mid life upgrades, they are retrofitted to full standards.

This is the story of every aircraft. Even the Su-30MKI initial deliveries in batches were not "Full MKI".

https://www.bharat-rakshak.com/IAF/Gall ... Induction/

Of these first 32 Su-30MKI, the first MKI squadron was deployed at Pune close to HAL Nashik and the second MKI squadron at Bareilly, again not a forward base. Though by now they would be upgraded to full standards.The 10 Su-30 MKI aircraft of this squadron started arriving in semi-knocked down condition soon after,with the first bach of two MKIs landing on 25 June 2002 aboard an An-124....The second consignment of 12 aircraft will be delivered by June 2003.The third consignment of 10 aircraft will be completed by end 2003/beginning 2004.On completion of the delivery of the third consignment,Su-30K and the earlier MKI variants will be upgraded to the standards of the third consignment.

And manufacture of Su-30MKI at HAL Nashik started 2004 after full MKI standard ICY was achieved.

From first flight of Su-30MKI in 1997, it took until 2004 for production of the "full MKI" to start

Last edited by tsarkar on 16 Oct 2020 18:38, edited 1 time in total.

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

^^^

tsarkar, Su30's MKI standard was more to do with capability rather than ICY standard. Isn't it? If I may quote Wiki:

"The first batch were eight Su-30MKs, the basic version of Su-30. The second batch were to be 10 Su-30Ks with French and Israeli avionics. The third batch were to be 10 Su-30MKIs featuring canard foreplanes. The fourth batch of 12 Su-30MKIs and final batch of 10 Su-30MKIs were to have the AL-31FP turbofans."

tsarkar, Su30's MKI standard was more to do with capability rather than ICY standard. Isn't it? If I may quote Wiki:

"The first batch were eight Su-30MKs, the basic version of Su-30. The second batch were to be 10 Su-30Ks with French and Israeli avionics. The third batch were to be 10 Su-30MKIs featuring canard foreplanes. The fourth batch of 12 Su-30MKIs and final batch of 10 Su-30MKIs were to have the AL-31FP turbofans."

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Basant, Wiki is incorrect.

The first 18 Su-30K were all K's without any French or Israeli avionics. They were returned.

The remaining 32 had canards and Al-31FP engines from the start.

Read the Bharat Rakshak Link I posted. The writer and photographer is member Kapil Chandni. He personally attended the Su-30MKI induction ceremony in September 2002. His facts are absolutely correct

You can see Su-30MKI in Pune with canards and Al-31FP engines from September 2002 itself.

Also check this aircraft walkaround from September 2002 http://www.bharat-rakshak.com/IAF/Galle ... s/Su30MKI/

The Litening Pod is there in September 2002. The drooping TVC nozzles of AL-31FP is there in September 2002. Request someone to update wiki with Kapil's notes.

I also discovered the trapeze pylon. Looks like NGARM uses a standard Russian trapeze pylon that with a longer forward arm to impart a downward tilt to the missile while dropping it.

http://www.bharat-rakshak.com/IAF/Galle ... 6.jpg.html

So my earlier post in the missile thread was wrong.

The first 18 Su-30K were all K's without any French or Israeli avionics. They were returned.

The remaining 32 had canards and Al-31FP engines from the start.

Read the Bharat Rakshak Link I posted. The writer and photographer is member Kapil Chandni. He personally attended the Su-30MKI induction ceremony in September 2002. His facts are absolutely correct

You can see Su-30MKI in Pune with canards and Al-31FP engines from September 2002 itself.

Also check this aircraft walkaround from September 2002 http://www.bharat-rakshak.com/IAF/Galle ... s/Su30MKI/

The Litening Pod is there in September 2002. The drooping TVC nozzles of AL-31FP is there in September 2002. Request someone to update wiki with Kapil's notes.

I also discovered the trapeze pylon. Looks like NGARM uses a standard Russian trapeze pylon that with a longer forward arm to impart a downward tilt to the missile while dropping it.

http://www.bharat-rakshak.com/IAF/Galle ... 6.jpg.html

So my earlier post in the missile thread was wrong.

Last edited by tsarkar on 16 Oct 2020 20:44, edited 1 time in total.

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Precisely. Which is why people need to be patient and wait for the production to stabilize before larger orders can be placed.suryag wrote:Not that we dont know of this or we havent discussed, however moving from proto to production is the most difficult thing, echoed by Elon Musk recently, HAL is getting there

Elon Musk

@elonmusk

Replying to

@elonmusk

The extreme difficulty of scaling production of new technology is not well understood. It’s 1000% to 10,000% harder than making a few prototypes. The machine that makes the machine is vastly harder than the machine itself.

It takes 9 months to get a baby and 18 years for the baby to become a productive adult. No matter what one does can shorten that process.

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Thanks tsarkar for the informative response

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Note FOC AOA has been opened up to 24*. So take that as your maximum. Unfortunately cannot compare with Bandar. Since Bandar never flies. Gripen is 26 (purported).fanne wrote:so what was AOA? Instant one and it was able to sustain itself? Any idea how does it compare to its counterpart - Gripen and Blunder?

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Tsarkar ji thats the wrong conclusion to draw from that. Only if you place orders of reasonable and sizeable quality can you enable production tool chains. Im sure you would agree it is stupid and foolish to think one can make a production chain without producing sizeable quantities.

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

To answer this question,suryag wrote:Tsarkar ji thats the wrong conclusion to draw from that. Only if you place orders of reasonable and sizeable quality can you enable production tool chains. Im sure you would agree it is stupid and foolish to think one can make a production chain without producing sizeable quantities.

Manufacturing is always in blocks to strike a balance between achieving consistency while ensuring economic viability of the production line.

For example, Navy ships are built in blocks of 3 or 4 to ensure one gains enough experience before making the next iteration. 3 Delhi followed by 3 Kolkata followed by 4 Vishakhapatnam. Or 3 Shivalik followed by 7 Nilgiris. 4 Kukhri followed by 4 Kora. 3 Talwar followed by 3 Teg followed by 4

The IAF does in blocks of 32/36/40 -

40 Batch 1 Jaguars followed by batches of similar size

40 Mirage 2000 followed by 9 followed by 10.

46 MiG-29s followed by 23 more.

18+32 initial Su-30MKI followed by 40+18 additional/replacement 2007 orders followed by 42 additional 2012 orders. And 140 license manufacture by HAL

36 Rafales

40 Tejas

IAF has never inducted the first batch beyond this number for all its aircraft. Thereafter once consistency has been achieved, more numbers are ordered. Like 140 Su-30MKI or 83 Tejas Mk1A

But IAF never went ahead with manufacture starting right from MiG-21, 27, Jaguar, Su-30MKI until the first batch/block achieved consistency. All the previous lines attest to this pattern

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

AoA by itself is meaningless. The lift generated by a wing at 20 degrees AoA may be more than the another wing at 24 degree AoA.

-

putnanja

- BRF Oldie

- Posts: 4757

- Joined: 26 Mar 2002 12:31

- Location: searching for the next al-qaida #3

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

The issue is that those batch sizes of 30-40 works well for imported orders, as those foreign defence firms have other orders and can hence production of scale kicks in. For indigenous products where Indian armed forces are the only customers, persisting with same batches makes little sense. Jaguar was ordered by British/French/India etc, Rafale for India/France/Qatar among others, similar for Mirage etc. If we persist with similar batch sizes, the cost becomes more than that for imported aircraft of similar capabilitiestsarkar wrote:To answer this question,suryag wrote:Tsarkar ji thats the wrong conclusion to draw from that. Only if you place orders of reasonable and sizeable quality can you enable production tool chains. Im sure you would agree it is stupid and foolish to think one can make a production chain without producing sizeable quantities.

Manufacturing is always in blocks to strike a balance between achieving consistency while ensuring economic viability of the production line.

For example, Navy ships are built in blocks of 3 or 4 to ensure one gains enough experience before making the next iteration. 3 Delhi followed by 3 Kolkata followed by 4 Vishakhapatnam. Or 3 Shivalik followed by 7 Nilgiris. 4 Kukhri followed by 4 Kora. 3 Talwar followed by 3 Teg followed by 4

The IAF does in blocks of 32/36/40 -

40 Batch 1 Jaguars followed by batches of similar size

40 Mirage 2000 followed by 9 followed by 10.

46 MiG-29s followed by 23 more.

18+32 initial Su-30MKI followed by 40+18 additional/replacement 2007 orders followed by 42 additional 2012 orders. And 140 license manufacture by HAL

36 Rafales

40 Tejas

IAF has never inducted the first batch beyond this number for all its aircraft. Thereafter once consistency has been achieved, more numbers are ordered. Like 140 Su-30MKI or 83 Tejas Mk1A

But IAF never went ahead with manufacture starting right from MiG-21, 27, Jaguar, Su-30MKI until the first batch/block achieved consistency. All the previous lines attest to this pattern

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

[rant on]My idea:

We should copy the western aryans and have our own version of pardon the turkey and pardon drdo instead spanning 9 days.

The MoD, Armed forces, the guy with the big bag of money should order a token qty of each item drdo produced on each day like 20 LCA, 20 Stags, 20 arjuns, 1 aew, 100 bombs etc.

At the end of 9 days we should display everything we bought last year and worship them.

If we have excess bombs and rockets we should go to the border and use them all.

This entire duration should be celebrated as 'The Great Indian Featival'.

[rant off]

We should copy the western aryans and have our own version of pardon the turkey and pardon drdo instead spanning 9 days.

The MoD, Armed forces, the guy with the big bag of money should order a token qty of each item drdo produced on each day like 20 LCA, 20 Stags, 20 arjuns, 1 aew, 100 bombs etc.

At the end of 9 days we should display everything we bought last year and worship them.

If we have excess bombs and rockets we should go to the border and use them all.

This entire duration should be celebrated as 'The Great Indian Featival'.

[rant off]

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

So your claim is that 135+ planes of the PAF have been permanently grounded and that whatever IAF controllers saw was a mirage ?disha wrote: Note FOC AOA has been opened up to 24*. So take that as your maximum. Unfortunately cannot compare with Bandar. Since Bandar never flies. Gripen is 26 (purported).

We need not be so shy or afraid

The very first link from global security.org talks about AoA claimed for the JF-17 as 26 deg and for F16 as 28 deg.

https://www.globalsecurity.org/military ... a/fc-1.htm

AoA is not the be all and end all, or the single determinative factor for how quickly a plane can gain altitude. Nor does that decide winners or losers

-

Saichand K

- BRFite -Trainee

- Posts: 8

- Joined: 29 Sep 2016 21:41

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

The below link indicates that AoA was updated to 26 degrees and prototype Tejas can pull of 8.5G/-3.5G as wellSo your claim is that 135+ planes of the PAF have been permanently grounded and that whatever IAF controllers saw was a mirage ?

We need not be so shy or afraid

The very first link from global security.org talks about AoA claimed for the JF-17 as 26 deg and for F16 as 28 deg.

http://delhidefencereview.com/2019/02/2 ... er-part-i/

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

That same link (co-authored by Indranil) says that in-service limits are 24 . (The test pilots took it to 26. It's possible that test pilot flights/planes may have additional safety measures such as spin recovery chutes etc; possibly he can shed light on this rather minor point ). What's confusing is what the IAF requirements are

http://ajaishukla.blogspot.com/2013/07/ ... -into.html says that the IAF asked for 26 deg. https://defenceupdate.in/sinusoidal-journey-lca-tejas/ talks about 1995 ASR asking for 24 degrees. A later IAF ask could explain it.

http://ajaishukla.blogspot.com/2013/07/ ... -into.html says that the IAF asked for 26 deg. https://defenceupdate.in/sinusoidal-journey-lca-tejas/ talks about 1995 ASR asking for 24 degrees. A later IAF ask could explain it.

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

IAF's requirements are not in terms of AoA. Because frankly, that is not IAF's job. IAF's job is define the minimum turning performance at various speeds.

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Totally agree on the bolded part. Okay vehemently agree.Barath wrote:So your claim is that 135+ planes of the PAF have been permanently grounded and that whatever IAF controllers saw was a mirage ?disha wrote: Note FOC AOA has been opened up to 24*. So take that as your maximum. Unfortunately cannot compare with Bandar. Since Bandar never flies. Gripen is 26 (purported).

We need not be so shy or afraid

The very first link from global security.org talks about AoA claimed for the JF-17 as 26 deg and for F16 as 28 deg.

AoA is not the be all and end all, or the single determinative factor for how quickly a plane can gain altitude. Nor does that decide winners or losers

My response on AoA was on a query on what is the angle at which Tejas at the display peeled out from ultra low level straight flight. And I mentioned that the AoA is 24*. One can use that as guidance. After that you took the post in a tangent. Since the second part of the post was just alluding to the bolded part. One can only compare if Bandars fly in airshows. Or fly at all. Since they do not fly, no point in paper comparison!

On the comparison part, comparing Tejas to Bandar is futile. It does not matter if the AoA on Bandar is either 26* or 69*. I think it is 69*.

Barath'ji, and I also think the underlined statement above in your post is to me your own unconsciousness doing a recursivity. Let's leave it at that.

Yes, 120+ Bandars of PAF are grounded. Just because 15 are flying does not mean that all of the Bandars are flying. You will have to prove to me that Bandars are flying at least 400 hours average in a year and all their uptime is 75%.

Till then 4 or so odd bandars showing up on the radar are just blips.

-

Cain Marko

- BRF Oldie

- Posts: 5627

- Joined: 26 Jun 2005 10:26

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

While your larger point remains, a note about flying hours. I doubt the best in the world get more than 200-250 hours per year on a given airframe.disha wrote:[You will have to prove to me that Bandars are flying at least 400 hours average in a year and all their uptime is 75%.

Till then 4 or so odd bandars showing up on the radar are just blips.

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

The size I was referring to was for the initial batch. IAF asked HAL to build 125 Jaguar and 140+40+18+42+12 Su-30 after the first batchputnanja wrote:The issue is that those batch sizes of 30-40 works well for imported orders, as those foreign defence firms have other orders and can hence production of scale kicks in. For indigenous products where Indian armed forces are the only customers, persisting with same batches makes little sense. Jaguar was ordered by British/French/India etc, Rafale for India/France/Qatar among others, similar for Mirage etc. If we persist with similar batch sizes, the cost becomes more than that for imported aircraft of similar capabilities

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

https://twitter.com/hvtiaf/status/13208 ... 27713?s=20 ---> LCA-SPORT program renamed LCA-LIFT (Lead-In Fighter-Trainer) in keeping with international conventions.

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

I think TDs are decommissioned. What is the status of 6 PVs?

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

https://www.ada.gov.in/images/flighttestnews.htmbasant wrote:I think TDs are decommissioned. What is the status of 6 PVs?

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Replying to this post from Rafale thread here:

Kids are not engineered items so the comparison is moot. I have yet to understand this, so perhaps you may be kind enough to explain how this is possible:

I am genuinely trying to understand this.

Sire, while an engineer by profession, I am not a process or an industrial engineer. My background is different engineering, but I do practice enough to get by.tsarkar wrote: Absolutely. Its very simple to comprehend if you think logically and reasonably. The Mi-25/35 with 1000's produced and operated has a well established support base. So even numbers as low as 10 can be maintained and supported.

Same with most of the major MMRCA contenders. F-16 for example with 1000's flying. So neither maintenance nor logistics will be any problem

Its ICY and not ICQ

Yes, unless production standards are reached, it cannot be mass produced. And unless it reaches mass production standards, logistics will indeed be a nightmare. Once production standards are reached, the initial aircraft are retrofitted.

Typically for aircraft like Jaguar, Mirage 2000, MiG-29, Rafale its the OEM nation that end up using the initial non standard aircraft and they typically use it for training & operational conversion. So that headache is absorbed by OEM nation and the buying nation gets standardized aircraft.

Even after a students graduates (FOC) and clears a job interview (SQR), he stays on probation (ICY) for some time before his employment is confirmed.

They are called probationary officers in Government of India terminology

https://www.sbi.co.in/web/careers/probationary-officers

.......

*snip*

Kids are not engineered items so the comparison is moot. I have yet to understand this, so perhaps you may be kind enough to explain how this is possible:

- A design authority specifies the design of an item which includes among other things, dimensions and more importantly tolerances. The tolerances are there exactly to state how much deviation from the design can be allowed and yet the item will do its function. The tolerance can be on anything: dimensions, load bearing etc etc. By all evidences ADA is a competent design authority that can do this.

- The manufacturing authority produces the item. It has a QA team that will reject anything that does not fall into the tolerances set. By all evidences, HAL is a competent manufacturing authority given its track record. HAL uses latest manufacturing machines (CNCs, laser cutters etc etc.) to ensure items are created within tolerances

- The manufacturing authority uses trial runs to iron out issues, one of which is producing items consistently. HAL has used LSPs just for this purpose

I am genuinely trying to understand this.

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Tanaji, I'm guessing that the LSP models have small design changes in them as they were still being tweaked while they were manufactured. That's why no two planes are exactly alike.

Once the design is frozen and the plane moves into mass manufacturing, they will be exactly alike.

Once the design is frozen and the plane moves into mass manufacturing, they will be exactly alike.

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Csaurabh:

Thank you but thats exactly my point. The current SP series of planes of which there will be 40 should be alike. The assertion is that these are not and is one of the reasons why IAF has not ordered 83 more yet (not my assertion).

Thank you but thats exactly my point. The current SP series of planes of which there will be 40 should be alike. The assertion is that these are not and is one of the reasons why IAF has not ordered 83 more yet (not my assertion).

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

That assertion, is pure hogwash.Tanaji wrote:Csaurabh:

Thank you but thats exactly my point. The current SP series of planes of which there will be 40 should be alike. The assertion is that these are not and is one of the reasons why IAF has not ordered 83 more yet (not my assertion).

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Are all 40 really alike?Tanaji wrote:Thank you but thats exactly my point. The current SP series of planes of which there will be 40 should be alike. The assertion is that these are not and is one of the reasons why IAF has not ordered 83 more yet (not my assertion).

Firstly, lets define "alike" from the below news report on HAL

https://english.mathrubhumi.com/news/in ... -1.1373414achieving ICY or interchangeability standards. (ICY ensures quick replacement of a component without any design changes affecting operational performance.)

https://english.mathrubhumi.com/news/in ... -1.2464308The SP-3 comes with more value additions with around 340 pipelines and 50 panels now achieving ICY or interchangeability standards. (ICY ensures quick replacement of a component without any design changes affecting operational performance.) “In the next aircraft, around 100 panels and 700-plus pipelines will be in the ICY standards,” says an official

Summarizing HAL statements,says Sridharan, who has been credited with establishing the new LCA Division. He says the LCA Division developed ICY (interchangeability) tools for all 147 panels and for 830 pipelines out of 934 pipelines within the build of first seven SP Tejas aircraft itself

SP3 - 50 Panels and 340 pipelines are achieving ICY

SP4 - Around 100 Panels and 700+ pipelines are achieving ICY

by SP7 - All 147 panels and for 830 pipelines out of 934 pipelines are achieving ICY

How do you reconcile your statement (in bold) with what Sridharan, who has been credited with establishing the new LCA Division, and the other HAL official said?

https://twitter.com/DynamaticTech/statu ... 2280088577Tanaji wrote:The current SP series of planes of which there will be 40 should be alike.

Again, how can all 40 are alike when the first ICY jig for #Tejas #LCA Front Fuselage Assembly gets clearance in September 2020 when as per the first page on this thread, 18 aircraft flew before the ICY Jig got clearance on 30-September-2020@DynamaticTech gets First Article-ICY Jig clearance from @HALHQBLR for #Tejas #LCA Front Fuselage Assembly. This is a milestone in our Nation’s Aerospace journey and #MakeInIndia

Please reconcile between what Sridharan, the HAL official and Dynamatic Tech are saying and what you are saying.SP-01 ... LA-5001 ... 01-Oct-2014

SP-18 ... LA-5018 ... 24-Sep-2020

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Kartik,Kartik wrote:That assertion, is pure hogwash.Tanaji wrote:Csaurabh:Thank you but thats exactly my point. The current SP series of planes of which there will be 40 should be alike. The assertion is that these are not and is one of the reasons why IAF has not ordered 83 more yet (not my assertion).

Firstly, can you give me an example of any aircraft ordered in large numbers before production was standardized?

I'll give the example of Saab Gripen

https://en.wikipedia.org/wiki/Saab_JAS_ ... en#Origins

Did the Swedes order in 100's before production was standardized?On 30 June 1982, with approval from the Riksdag, the FMV issued contracts worth SEK 25.7 billion to Saab, covering five prototypes and an initial batch of 30 production aircraft.

Secondly, when making a point, do provide facts to substantiate them.

Thirdly, I leave it to the intelligence of the reader to decide who is stating "pure hogwash". Someone stating facts quoting Sridharan verbatim or someone stating his pet biases and fantasies completely detached from reality

Lastly,

1. nothing written here,

2. no matter how much emotions one stuffs in their post

3. no matter how much anyone abuses someone else

changes the ground reality which is what Sridharan said or what Dynamatics achieved.

Military matters go by "hosh" and not "emotions". Emotions never won any war.

Last edited by tsarkar on 31 Oct 2020 19:04, edited 1 time in total.

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

What is wrote is absolutely correct in terms of quality but not correct in terms of standardization for mass production.Tanaji wrote:I have yet to understand this, so perhaps you may be kind enough to explain how this is possible:

If the above 2 are correct, how does one get a plane with individual one-off parts that cannot be interchanged? In old days, it happened because we did not have the skills or the machines to reach these tolerances. Now, we do.

- A design authority specifies the design of an item which includes among other things, dimensions and more importantly tolerances. The tolerances are there exactly to state how much deviation from the design can be allowed and yet the item will do its function. The tolerance can be on anything: dimensions, load bearing etc etc. By all evidences ADA is a competent design authority that can do this.

- The manufacturing authority produces the item. It has a QA team that will reject anything that does not fall into the tolerances set. By all evidences, HAL is a competent manufacturing authority given its track record. HAL uses latest manufacturing machines (CNCs, laser cutters etc etc.) to ensure items are created within tolerances

- The manufacturing authority uses trial runs to iron out issues, one of which is producing items consistently. HAL has used LSPs just for this purpose

I am genuinely trying to understand this.

For example LCA Technology Demonstators were high quality machines. However 1. they were built one off in the lab. 2. LCA TD's did not fulfill the full set of flight characteristics

Flight characteristics and systems integration were to take place in the Prototype Vehicles (PV)

Production standardization was to happen in Limited Series Production (LSP)

However the development program itself turned out to be more complex than initially estimated. more airframes were required for testing and the LSP's were used for development instead of production standardization.

Which is why you read news reports of LSP-X testing this and LSP-Y testing that when their nomenclature stated Limited Series Production. The LSP's were used as PVs.

The 40 orders in IOC and FOC configuration are the new "Limited Series Production" aircraft used to standardize production.

Which is also why they are in different ICY categories. Standardization is achieved over each aircraft manufactured.

Its only when standardization of production has been achieved over these 40 orders that mass production can really begin.

So its not about quality. Its about standardization for mass production.

Will anyone here buy a car whose parts, pipes, panels are non standardized even if the parts, pipes & panels are high quality?

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Read the other indicators -

The first two Su-30MKI squadrons (No 24, 20) were based at Pune close to HAL Nashik and where IAF 11 BRD is located.

The first two Tejas squadrons (No 45, 18) are based at Sulur Coimbatore close to HAL Bangalore.

Why? Because of non standardization, they will need higher maintenance and hence close to their factory or maintenance depot.

The first two Su-30MKI squadrons (No 24, 20) were based at Pune close to HAL Nashik and where IAF 11 BRD is located.

The first two Tejas squadrons (No 45, 18) are based at Sulur Coimbatore close to HAL Bangalore.

Why? Because of non standardization, they will need higher maintenance and hence close to their factory or maintenance depot.

Last edited by tsarkar on 31 Oct 2020 19:00, edited 1 time in total.

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

To add, there's also standardization of other assemblies and processes that comes about as statistics are improved with each new batch. Various relaxed software limits will also be tweaked as statistics become available.

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

So what happens to non ICY airframes ( non standardized) when standardized production starts?

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Every aircraft undergoes a mid life refit every 10/15 years. Then they are retrofitted to the latest standards.manjgu wrote:So what happens to non ICY airframes ( non standardized) when standardized production starts?

https://www.hindustantimes.com/india-ne ... qTxJJ.html

The 11 Base Repair Depot (BRD) of the Indian Air Force at Ojhar in Maharashtra’s Nashik district Friday handed over its first indigenously overhauled Sukhoi Su-30MKI fighter jet to the IAF, an official said.

Note South Western Air Command where the Su-30MKI was initially inductedAir Officer Commanding-in-Chief of the Maintenance Command Air Marshal Hemant Sharma handed over the aircraft to Air Marshal H S Arora, Air Officer Commanding-in-Chief of South Western Air Command, at a ceremony held at the Air Force Station Ojhar, about 200km from Mumbai, he said.

Established in 1974, the depot progressively built and improved the technical expertise and infrastructure over the years and by 1983 it had overhauled 100 Su-7 aircraft.

From 1983 to 1988, the depot also undertook an overhaul of MiG-21 fighters.

Later, the overhaul facility for MiG-23 aircraft was set up in 1986 and 248 jets were overhauled till May 2015, the official said.

Overhaul of MiG-29 aircraft commenced in 1996.

The upgradation of MiG-29 and repair and overhaul of Su-30 MKI aircraft is being undertaken at the depot, he said.

HAL also carries out refits and overhauls of Su-30MKI. More details here

http://ajaishukla.blogspot.com/2014/10/ ... ashik.html

A Su-30MKI is overhauled after flying 1,500 hours or 14 years, whichever is first. Over its total service life of 6,000 flying hours or 30-40 years, each fighter undergoes three overhauls. Eventually the IAF’s fleet of 272 Su-30MKIs will undergo 816 overhauls --- three per fighter.

“The MoD has sanctioned an overhaul capacity of 15 fighters per year; next year we will overhaul 10-12 fighters and then stabilize at 15 fighters annually. We have already approached the MoD to step up capacity to 30 fighters per year, which will cater for our requirements into the 2030s” says Subrahmanyan. Of the thirty Su-30MKIs that will be overhauled each year, HAL will do 20, while an IAF base repair depot will overhaul the other 10.

Last edited by tsarkar on 31 Oct 2020 21:35, edited 1 time in total.

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

so the non ICY are used for training and testing?? because if they are non ICY they need to be based near the factory or else they are a maintenance nightmare?

Re: Tejas Mk.1 & Mk.1A: News & Discussions: 23 February 2019

Mostly training. Because when you plan a large fleet, you need to train adequate pilots. That doesnt happen overnight.manjgu wrote:so the non ICY are used for training and testing?? because if they are non ICY they need to be based near the factory or else they are a maintenance nightmare?

We have a peculiar situation for Dhruv helicopters where HAL is churning out machines faster than Indian Army can train pilots to operate them, though that is due to age of Chetak helicopters used by IA to train Army Aviation Corps pilots.

Training is of multiple levels.

1. Initial training is conversion on a two seater with an instructor

2. Then flying the type solo

3. Then "consolidation of general handling"

4. Then "tactical flying and maneuvers"

5. Then "air to air" and "air to ground"

6. Then they become fully operational by day

7. Then "dark phase" starts

8. Followed by fully operational by night

9. This whole process takes "upwards of a year"

Details from here, the website isnt allowing copy paste.

https://timesofindia.indiatimes.com/ind ... 609283.cms

Like the aircraft, even the pilots are thoroughly certified.

This is what the Su-30MKI initial aircraft did and this is what the two squadrons of Tejas will do at Sulur and this is what the two Rafale squadrons will do at Ambala and Hashimara.

Also training of the maintenance engineers. Needless to say, there are many more engineers to train at TETTRA than pilots.