Kaveri & Aero-Engine: News & Discussion

Re: Kaveri & Aero-Engine: News & Discussion

I think why Brahmos got the ab section is, it is mostly a production agency. The r&d of ab version was already done (by gtre?) and has been given to a firm that is in production of matellic parts to make it. I suspect some of the material and know how on its handling may come from Mishra Dhatu Nigam Limited.

Re: Kaveri & Aero-Engine: News & Discussion

Maitya ji,

Question for you. I have been taking gyan from chat gpt. It looks like when you flat rate an engine, (compared to non flat rating), you put more thermal stress, repeated heating and cooling cycles. That means better metallurgy.

I understand why flat eating is needed in our condition, but all our imported engines (and planes) do not have flat rating and they are doing just fine. Why choose a more difficult path when you are technology wise behind the countries where we are importing these engines from? Was it planned to fail? Or put differently too ambitious and perhaps impractical?

Question for you. I have been taking gyan from chat gpt. It looks like when you flat rate an engine, (compared to non flat rating), you put more thermal stress, repeated heating and cooling cycles. That means better metallurgy.

I understand why flat eating is needed in our condition, but all our imported engines (and planes) do not have flat rating and they are doing just fine. Why choose a more difficult path when you are technology wise behind the countries where we are importing these engines from? Was it planned to fail? Or put differently too ambitious and perhaps impractical?

Re: Kaveri & Aero-Engine: News & Discussion

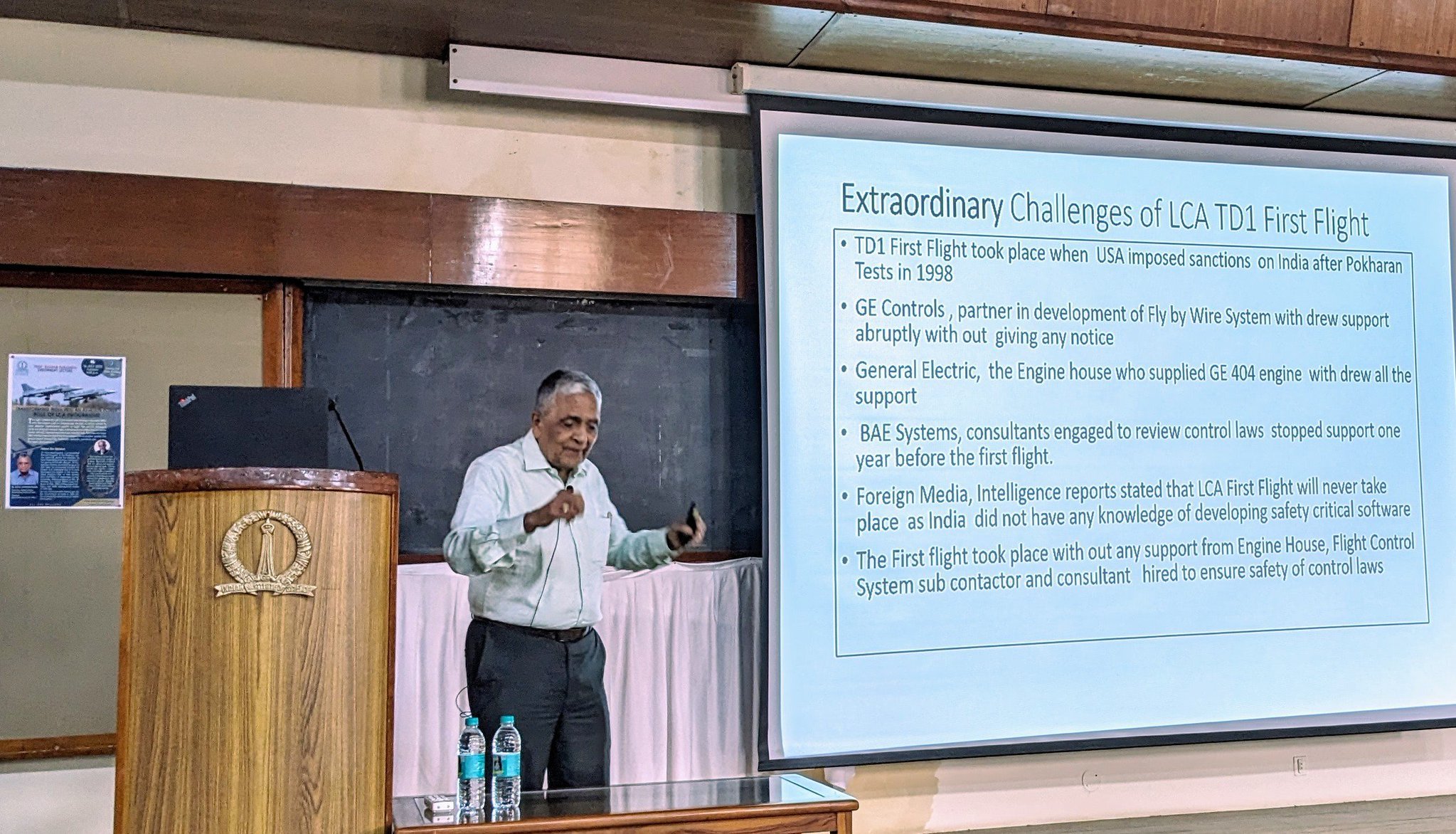

People should read this before talking about 100% ToT and IPR

And anyone who thinks that the goras are not cartelized should think again

And anyone who thinks that the goras are not cartelized should think again

-

Mukesh.Kumar

- BRFite

- Posts: 1441

- Joined: 06 Dec 2009 14:09

Re: Kaveri & Aero-Engine: News & Discussion

Ok, Flat Rating is needed to make life easier for pilots so that they don't have to worry about Take Off Weights under different conditions.fanne wrote: ↑21 Jul 2024 03:26 Maitya ji,

Question for you. I have been taking gyan from chat gpt. It looks like when you flat rate an engine, (compared to non flat rating), you put more thermal stress, repeated heating and cooling cycles. That means better metallurgy.

I understand why flat eating is needed in our condition, but all our imported engines (and planes) do not have flat rating and they are doing just fine. Why choose a more difficult path when you are technology wise behind the countries where we are importing these engines from? Was it planned to fail? Or put differently too ambitious and perhaps impractical?

I guess this learning came from the challenges that the F-16 faced in taking off from Ladakh during the MRCA trials.

Re: Kaveri & Aero-Engine: News & Discussion

fanne-ji, the answer is quite nuanced, and requires slightly detailed explanation - will post in detail once have got some b/w to type it out.fanne wrote: ↑21 Jul 2024 03:26 Maitya ji,

Question for you. I have been taking gyan from chat gpt. It looks like when you flat rate an engine, (compared to non flat rating), you put more thermal stress, repeated heating and cooling cycles. That means better metallurgy.

I understand why flat eating is needed in our condition, but all our imported engines (and planes) do not have flat rating and they are doing just fine. Why choose a more difficult path when you are technology wise behind the countries where we are importing these engines from? Was it planned to fail? Or put differently too ambitious and perhaps impractical?

However, do note, it's not for nothing (for very few) Kaveri is still considered way out of her time/future-proof .

And the beauty is the simplicity of the solution thought about it, almost from the first principles, and actually was first implemented and proven in it's predecessor engine (pls refer to the Kaveri gyan thread for the Kaveri lineage).

More on it later but must say one thing - there's always a price to be paid for any such "off design point" compromises, and Kaveri was/is no exception.

Most established engine houses are still grappling to bring out solution to this, and it's not too difficult to find out what those are (e.g. variable cycle engine etc).

Another way of putting this would be, that the Kaveri designers could have gone for the glory (aka shiny brochure based ratings) in it's design, but they didn't - as for them, their design choices were 100% geared for a desi-Indian problem resolution, and provide the user with a product that they can proudly call "their own" (as it solved their own, somewhat unique, problems) - maybe foolishly, as many would now infer, 3+ decades later.

Betw not sure who told that the imported engines are doing "just fine" - ofcourse it's blasphemous for the user community to speak ill (or shortcomings) of imported maal, so you wouldn't hear about it - but there're are enough hints, here and there, to understand it.

Recently, in this very thread, the actual wet thrust being expected from the F414s, was very inadvertently let out - of course, people can visit various OEM websites and other rah-rah articles about them and keep dreaming about the thrust ratings mentioned in various technicolor and sleek brochures. It's their choice!!

Reality ofcourse is quite different, but being imported, you won't get any whiff of it from various "seminar talks", webcasts, interviews etc etc from those who once had actually used them, and are thus well aware of the issue.

Re: Kaveri & Aero-Engine: News & Discussion

Maitya ji,

Mine was mainly focused on, I need a working engine, if I can get same as say f404, it will solve lca mk1 problem. F404 for good or bad is working for lca mk 1. If I can get a working engine, even if it is exactly same as it, I cannot be shadow sanctioned. I do not understand the IP implication of this.

Today we have nothing. And I have 3 decades of hindsight. The Kaveri developers may have not known that this would be the fate. Can the material teach knowledge gained from Kaveri be used to make an exact clone of f404 (assuming it is easier material wise)?

Mine was mainly focused on, I need a working engine, if I can get same as say f404, it will solve lca mk1 problem. F404 for good or bad is working for lca mk 1. If I can get a working engine, even if it is exactly same as it, I cannot be shadow sanctioned. I do not understand the IP implication of this.

Today we have nothing. And I have 3 decades of hindsight. The Kaveri developers may have not known that this would be the fate. Can the material teach knowledge gained from Kaveri be used to make an exact clone of f404 (assuming it is easier material wise)?

Re: Kaveri & Aero-Engine: News & Discussion

I know I'll get mercilessly trolled for saying this - but do note, material tech wise, Kaveri is atleast a gen ahead of F404-402, and maybe even the IN20 variant.fanne wrote: ↑24 Jul 2024 17:00 Maitya ji,

Mine was mainly focused on, I need a working engine, if I can get same as say f404, it will solve lca mk1 problem. F404 for good or bad is working for lca mk 1. If I can get a working engine, even if it is exactly same as it, I cannot be shadow sanctioned. I do not understand the IP implication of this.

Today we have nothing. And I have 3 decades of hindsight. The Kaveri developers may have not known that this would be the fate. Can the material teach knowledge gained from Kaveri be used to make an exact clone of f404 (assuming it is easier material wise)?

You can simply compare the TeT capability of Kaveri/Kabini and that of F404 (or AL-31F or even AL-41F, or RD-33 series etc), and make inferences about the material tech capability etc.

But the issue is 1000s of F404 have been produced compared to 0 for Kaveri, so claiming such capabilities etc is not going to mean much.

It's more in the league of F414 (baseline version), but then again all this can be easily disproven by simply stating "show me the series-produced material tech capability of Kaveri" etc - as there are no series produced Kaveri in the first place.

And lab-proven capability doesn't really count wrt proven TF series-manufacturing capability etc etc.

Re: Kaveri & Aero-Engine: News & Discussion

So the obvious question now, pretend for the sake of argument that we are shadow banned for f404. It will come in trickle and as soon as we find a solution, all the needed engine will be miraculously delivered the next day ( us equivalent of we found that made in a remote warehouse and because of software glitch did not know they were made). So to get these engines, can we make a copy paste of f404in20 with our material? What are IP implication of that. It looks like we did not care about IP when we made clear detergents or say missiles like Agni. But those are strategic. We can always paint the engine green and said we got it from tsp, when they were hauled by the Texan congressman freedom fighter over Yellow Sea. Is that blatant ip par on course?

Re: Kaveri & Aero-Engine: News & Discussion

Why I am saying same is because you don’t want to waste time on design. Our ground up design is kaveri

Re: Kaveri & Aero-Engine: News & Discussion

Another question for Maitya Ji- What's the big deal with the engine being overweight, one can easily compensate that by making plane lighter (say with more composite) or perhaps lug one missile less or lesser fuel, a compromise but not a deal killer.

Is that because a lighter engine, meaning the sections that rotate (fan etc.), if lighter can rotate faster for the same amount of fuel burn (thus increasing thrust). If this is so, then an overweight afterburner does not hurt that much (as it is not rotating). For that,a theoretical overweight engine casing would not hurt. I am here disregarding brochure thrust to weight ratio of engine. It is an indicator of how light the rotating parts are, but in theory you can have a very light rotating part and heavier non rotating parts of the engine. Agreed that lower weight of all parts is anyway beneficial.

The improved Kaveri have these -

***************

DRDO Trims Kaveri Engine Weight to 1180kg, Plans to Achieve Less Than 1-Ton

In a major boost for India's self-reliance in defence technology, the DRDO has achieved a substantial weight reduction in the Kaveri derivative jet engine.

The current combined weight of the engine and afterburner stands at approximately 1180 kg, down from 1235 kg and considerably less than the initial prototypes which weighed over 1400 kg. This remarkable reduction can be attributed to several key factors:

New Fan Module: A newly developed, lighter, and more efficient fan module has significantly contributed to the overall weight savings.

Core Changes: Extensive modifications and optimizations in the engine core have addressed previously over-engineered sections, resulting in further weight reduction and potential performance enhancements.

Afterburner Module: The afterburner section has also undergone substantial weight reduction, shedding 70-90 kg while maintaining its functionality and efficiency.

*************

Afterburner module weight savings may not have same impact as thefan module weight saving will have. I am completely ignoring CG changes etc.

Is that because a lighter engine, meaning the sections that rotate (fan etc.), if lighter can rotate faster for the same amount of fuel burn (thus increasing thrust). If this is so, then an overweight afterburner does not hurt that much (as it is not rotating). For that,a theoretical overweight engine casing would not hurt. I am here disregarding brochure thrust to weight ratio of engine. It is an indicator of how light the rotating parts are, but in theory you can have a very light rotating part and heavier non rotating parts of the engine. Agreed that lower weight of all parts is anyway beneficial.

The improved Kaveri have these -

***************

DRDO Trims Kaveri Engine Weight to 1180kg, Plans to Achieve Less Than 1-Ton

In a major boost for India's self-reliance in defence technology, the DRDO has achieved a substantial weight reduction in the Kaveri derivative jet engine.

The current combined weight of the engine and afterburner stands at approximately 1180 kg, down from 1235 kg and considerably less than the initial prototypes which weighed over 1400 kg. This remarkable reduction can be attributed to several key factors:

New Fan Module: A newly developed, lighter, and more efficient fan module has significantly contributed to the overall weight savings.

Core Changes: Extensive modifications and optimizations in the engine core have addressed previously over-engineered sections, resulting in further weight reduction and potential performance enhancements.

Afterburner Module: The afterburner section has also undergone substantial weight reduction, shedding 70-90 kg while maintaining its functionality and efficiency.

*************

Afterburner module weight savings may not have same impact as thefan module weight saving will have. I am completely ignoring CG changes etc.

Re: Kaveri & Aero-Engine: News & Discussion

We know what the problem is. 20 years ago, people would be banned for even alluding to who and which organization/building they belong to.

I have always felt a republic guard like force could be built out of all MHA forces and could be the driver for these kind of projects. I don’t know why BSF’s airwing or ITBP’s forces cannot have these products. LCA lift would be a very potent addition to regular patrols (not cap, that would be still IAF).

I have always felt a republic guard like force could be built out of all MHA forces and could be the driver for these kind of projects. I don’t know why BSF’s airwing or ITBP’s forces cannot have these products. LCA lift would be a very potent addition to regular patrols (not cap, that would be still IAF).

Re: Kaveri & Aero-Engine: News & Discussion

What if we, for the sake of argument, start doing joint development with certain other countries, so that we both together find that solution?

I'm talking about countries that US would not like to see find such solutions.

Will that perhaps encourage the US to be a little more forthcoming, instead of playing the shadow-ban game?

I feel that we've not been creative enough in our responses to US games.

I feel that by going in for more joint development with other countries, then it will help to defray our development costs, which we have no choice to but to spend on, in the face of this shadow-banning.( us equivalent of we found that made in a remote warehouse and because of software glitch did not know they were made). So to get these engines, can we make a copy paste of f404in20 with our material? What are IP implication of that. It looks like we did not care about IP when we made clear detergents or say missiles like Agni. But those are strategic. We can always paint the engine green and said we got it from tsp, when they were hauled by the Texan congressman freedom fighter over Yellow Sea. Is that blatant ip par on course?

Re: Kaveri & Aero-Engine: News & Discussion

That image should be the sticky post for the LCA thread . And all threads where "engine tot" " fighter tot" is promoted.chetak wrote: ↑21 Jul 2024 15:47 People should read this before talking about 100% ToT and IPR

And anyone who thinks that the goras are not cartelized should think again

https://pbs.twimg.com/media/GSm5bJZbIAQ ... name=large

Indeed TOT is an oxymoron . The carrot hung in front of the horse.. never really reaching it.

Re: Kaveri & Aero-Engine: News & Discussion

Next Gen Aero Engines

https://www.sps-aviation.com/story/?id= ... gines&s=08

Issue: July 2024

By Air Marshal Anil Chopra (retd)

https://www.sps-aviation.com/story/?id= ... gines&s=08

Issue: July 2024

By Air Marshal Anil Chopra (retd)

Re: Kaveri & Aero-Engine: News & Discussion

Hanwha Introduces New KF-21 Engine Prototype at FIA-24

https://www.iiss.org/online-analysis/mi ... -in-china/

26 July 2024

https://www.iiss.org/online-analysis/mi ... -in-china/

26 July 2024

Re: Kaveri & Aero-Engine: News & Discussion

Maitya ji, can we make a clone of an AL-31FP locally without depending on Russia?

Re: Kaveri & Aero-Engine: News & Discussion

I continue to get asked this question, and frankly was trying to avoid replying to it, as there are no direct "yes" or "no" type answer to it - it's quite nuanced, and that'd mean another lengthy post, which I'm desperately trying to avoid currently (b/w etc issues galore).

But I'll bite - and try and keep the following as short as I'm able to:

Well short-and-sweet answer to it is, you guessed it, both "yes" and "no".

1) Why Yes:

Please note, for any turbofan mass manufacturing program there are four essential technological aspects that needs mastering.

a) Raw Materials

b) Turbomachinery mfg

c) Testing

d) Enduring Support for Operational usage.

The CFD and the design-aspects are equally (if not more) vital as well, but if the intent is to simply clone them, part-by-part, you'll receive enough CFD related details to continue to do so. Perf improvement etc won't come though, as without detailed CFD and design-related understanding (plus the integration/interplay between between various subsystems), it's virtually impossible to drive such initiatives.

One of the reason, you'll notice some news-items of improved indigenously manufactured parts are always pointing to MTBO type of improvements, but never on perf-parameter improvements. But I digress ...

Now, if you are able to mass-manufacture, even from imported raw materials, the entire turbofan for decades together - then essentially you have mastered all 3 viz. b, c and d.

The OEM would hate to let go the dependency, so the only option is to retain the control via "a", and in an round about way, via the "b" aspects.

Let me illustrate with a simple example how the dependence of the "b" aspects are achieved.

Let's take for example, and everybody's favorite here, the HPT blades (and vanes).

For it, "a" -> SC ingots but "b" is actually a multitude of turbo-machinery.

But for simplicity sake, just for this discussion here, let's restrict it to simple 4-5 of them:

Vacuum Investment Casting furnace, a high-pressure CIM (Ceramic Injection Molding), EBPVD setup for TBC, Laser Drilling setup for cooling holes and finally the LFW setup for joining the blades to the disc.

Now each of these machines are tailored (mostly deliberately by the OEM) only specifically applicable for that TF part/LRU (here HPT blades) - since the calibration of each of these machines are unique (the empirical config parameters are closely guarded secrets), you will remain dependent on importing these very same machines from tightly-knit OEM's vendor-supply-chain, as long as you are going to manfacture the TF.

But, if you are able to master the turbomachinery usage technology via another program that is of sufficient sophistication and maturity level, then bingo - nobody (except of course the, lordships in MoD baboon pantheons) would be able to stop you from calling the OEM bluff etc.

We, thanks to the much-maligned Kaveri program, are exactly at that point vis-a-vis the AL-31FP (and dare say the AL-41F as well), but not wrt the F414-INS6 (or the M88).

Now coming to the Raw materials (SC ingots etc, in this example), well, always remember the claim (from the extremely naval-gazing and reticent DRDO's scientific leadership) - there are no metallic superalloy (in the TF context), that we can't indigenously design and mass-manufacture in a 5-year time-period (7 years for intermetallic etc).

So, yeah we are currently dependent on the OEM, but it's safe to claim that GTRE/MIDHANI/DMRL et all, have the wherewithal to mass-manufacture the entire AL-31F TF on their own.

b) Why No:

There are multiple reasons, but the biggest of them, trying something like that would require good 5-7 years of dedicated effort and, you guessed it right, handsome budgetary support spanning quite a few years - which will never ever happen.

If MoD baboons et all, can kill a national strategic program like Kaveri, even after it achieved almost impossible levels of technologies etc (on leaner-than-shoe-string budgets), how on earth will they sanction "wasteful science projects" such as these.

Even here in BRF, a common rudali (in conjunction with the import-pasand shills) you'll hear is assembled engine costlier than the fully imported ones etc. etc.

Nothin wrt atmanirbharata will even come when the collective wisdom/attitude is such.

But there are other reasons as well - for example, we haven't yet demonstrated TVC in any of our programs, so there's a degree of uncertainty there as well.

But the second biggest issue is, the threat (from OEM) to the ops readiness of tip-of-the-spear platforms.

A hint of any such hanky-panky, OEM is simply going to pull the plug on the Warranty Support of the entire fleet - and the user will simply refuse to fly them with out-of-warranty engines.

And by the time, you have regained all aspects of the maturity/capability to restart mass-manufacturing of all systems/subsystems/LRUs etc, that's staring at a good 7-10 years of grounded platforms etc - which is unacceptable.

However, if such a program was initiated, say a decade+ back, maybe, just maybe, we'd be at a point to go for it now.

But there again, the geniuses (who'd had negotiated the mfg contract etc) didn't even try to get some form of indigenous part-replacement-without-warranty-voiding clauses, so no joy there as well.

And that's precisely the point I keep on advocating that for the F414 deal, we also negotiate this indigenous part-replacement-without-warranty-voiding clauses - after all none of these TFs are coming cheap, and F414 would be the mainstay of so many future programs etc. Fat chance of that happening though ...

As you may have noticed, the logic has become completely circular at this point.

But there's another aspect that needs understanding as well:

Why exactly is this clone etc required in the first place?

A healthy MRO (read stocking up of parts etc) will easily mitigate any threat to the intended-platform availability etc.

But if the intent is to somehow use it for another program - well consider the following:

You already have an indigenous TF program, that's minm a gen ahead of the AL-31F, in almost all aspects (except of the TVC aspects) - so, instead of such stunts, support that program itself. It'll not be very difficult to build (even easily surpass) an better-performing alternative to the AL-31F thrust-class TF, as an offshoot of that program itself.

Again fat-chance of even that happening though.

We'll ofcourse find funds for an OEM to complete the D&D and Mfg of their next wet-dream TF program(s), which their own Govts had decided, many years back, not to fund anymore - in return some ToAsT type assembly/mfg will be handed-down to us, and everybody would be happy.

Life goes on ...

Re: Kaveri & Aero-Engine: News & Discussion

Thanks Maitya ji you have spelled out all the pitfalls of pre-empting the vendor and of couse our Baboons in charge will never think along national priority lines. You need enlightened mantriji like Manohar Parrikar who made the IDDM route feasible for Tejas and artillery and other systems.maitya wrote:Now each of these machines are tailored (mostly deliberately by the OEM) only specifically applicable for that TF part/LRU (here HPT blades) - since the calibration of each of these machines are unique (the empirical config parameters are closely guarded secrets), you will remain dependent on importing these very same machines from tightly-knit OEM's vendor-supply-chain, as long as you are going to manfacture the TF.

The above caught my eye, which I completely agree. I spellt out details on Semiconductor Fabs which are similar. The other vendor machines are key to the manufacturing process and it is hard to circumvent them unless you know the ins and outs of the system.

I hope the kaveri program yields some good news after a long arduous journey.

Re: Kaveri & Aero-Engine: News & Discussion

5-7 years in dedicated effort is not an issue.. from upa2 times the need to upgrade su30mki and reducing dependence on OEM has been in focus. Significant progress has happened in terms of most russian LRUs. Real question would be how the Russian warranty claims is evaluated, especially during time of a war, disrupted logistics, and when the attacker is China. So a one to one duplicate of AL31 is may be one necessary step, despite the time taken or technical complexity. Agreed that IAF needs to be taken on board.

Last edited by Kailash on 16 Aug 2024 08:57, edited 1 time in total.

Re: Kaveri & Aero-Engine: News & Discussion

maitya wrote: ↑24 Jul 2024 17:14I know I'll get mercilessly trolled for saying this - but do note, material tech wise, Kaveri is atleast a gen ahead of F404-402, and maybe even the IN20 variant.fanne wrote: ↑24 Jul 2024 17:00 Maitya ji,

Mine was mainly focused on, I need a working engine, if I can get same as say f404, it will solve lca mk1 problem. F404 for good or bad is working for lca mk 1. If I can get a working engine, even if it is exactly same as it, I cannot be shadow sanctioned. I do not understand the IP implication of this.

Today we have nothing. And I have 3 decades of hindsight. The Kaveri developers may have not known that this would be the fate. Can the material teach knowledge gained from Kaveri be used to make an exact clone of f404 (assuming it is easier material wise)?

You can simply compare the TeT capability of Kaveri/Kabini and that of F404 (or AL-31F or even AL-41F, or RD-33 series etc), and make inferences about the material tech capability etc.

But the issue is 1000s of F404 have been produced compared to 0 for Kaveri, so claiming such capabilities etc is not going to mean much.

It's more in the league of F414 (baseline version), but then again all this can be easily disproven by simply stating "show me the series-produced material tech capability of Kaveri" etc - as there are no series produced Kaveri in the first place.

And lab-proven capability doesn't really count wrt proven TF series-manufacturing capability etc etc.

maitya ji,

All this leaves just one tiny little matter unaddressed

human resources

BTW, much of the metallurgical details of the Lyulka-Saturn and Klimov engines used by India have been available to us for many years now, and the few instances where details have not been provided, the same have been obtained by analysis by Indian labs and entities. We have been able to make many of these alloys, at times, even improving on them, but some others have eluded us so far.

The old codgers parading around in the corridors pf power have all failed miserably, jointly and severally, to put together a credible team of go getters who will be able to take this endeavour forward.

This is what the politicos see: no team, no credibility, which then translates to low priority and even lower funding

There is a direct and inescapable comparison to the space, nuclear, and missile programs. All of them started out as low priority, with negligible funding but they produced results and now rightfully occupy prime positions of pride in the public perception, nationally, as well as, internationally, and presto, funding is not going to be a problem for them

And because of his haifa port deal where he has (by his own choice) an israeli JV partner, he has a solid connection with the israelis. He outbid the cheen for this project

and yet, a few months ago, someone was whining about adani doing screwdrivergiri and making/assembling (armed ?) israeli drones in India, and "fooling the people" .....

He did not ask for govt funding, he put in his own money, hired his own team, found a JV partner, all by himself, all on his own initiative

पेड़ गिनने से मतलब है या आम खाने से

damned if you do and damned if you don't

So, at the end of the day, the question remains: How much wood could a woodchuck chuck, if a woodchuck could chuck wood?

It would appear that we have a good amount of wood, but sadly, no woodchucks

Re: Kaveri & Aero-Engine: News & Discussion

Was this posted before? looks like moves are underway even though not widely publicized.

Bharat Forge acquires 51% stake in Zorya Mashproekt

Bharat Forge acquires 51% stake in Zorya Mashproekt

At present, most of the Indian Navy’s warship uses the marine gas turbines from Ukraine’s Zorya as their primary source of propulsion.

Re: Kaveri & Aero-Engine: News & Discussion

Interesting, provided they get the intellectual property needed to seed programs in India. It is a great initiative.

Re: Kaveri & Aero-Engine: News & Discussion

KSSL acquired 51% stake in ZMI not in mother ZM. ZMI works in India for ZM engines maintenance, so fingers crossed. They may not have access to IPs, but they can get the know how.vera_k wrote: ↑20 Aug 2024 06:33 Was this posted before? looks like moves are underway even though not widely publicized.

Bharat Forge acquires 51% stake in Zorya Mashproekt

At present, most of the Indian Navy’s warship uses the marine gas turbines from Ukraine’s Zorya as their primary source of propulsion.

Re: Kaveri & Aero-Engine: News & Discussion

Ukraine Visit - Double Engine Sarkar?

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/alpha_defense/status/1827276822796747258 ---> GOI has approved funds for establishing an AL-31 test bed, a significant step towards enhancing self-reliance in defense. This initiative will advance the substitution of critical components with superior Indian-made alternatives, driving performance and innovation.

https://x.com/PrasadSatya10/status/1827324261553651751 ---> HAL Koraput had an AL-31P test bed. Can't manufacture and undertake ROH without ETB. What capabilities will the new test bed give?

https://x.com/alpha_defense/status/1827342754562621509 ---> I believe existing analog set up was termed test bench which was used for ground run test. This is test bed that will allow automated analysis of substituted items.

https://x.com/PrasadSatya10/status/1827343600507879443 ---> HAL has been designing test beds since long. "The centre is the only design house which has developed test beds for Engines of Western as well as Russian origin engines."

https://x.com/alpha_defense/status/1827344538702356814 ---> Yeah but during the event we were told that it will help us to gauge the performance of new components and this capability is new.

https://x.com/alpha_defense/status/1827346278046691645 ---> Which implies it was for TVC testing.

https://x.com/PrasadSatya10/status/1827324261553651751 ---> HAL Koraput had an AL-31P test bed. Can't manufacture and undertake ROH without ETB. What capabilities will the new test bed give?

https://x.com/alpha_defense/status/1827342754562621509 ---> I believe existing analog set up was termed test bench which was used for ground run test. This is test bed that will allow automated analysis of substituted items.

https://x.com/PrasadSatya10/status/1827343600507879443 ---> HAL has been designing test beds since long. "The centre is the only design house which has developed test beds for Engines of Western as well as Russian origin engines."

https://x.com/alpha_defense/status/1827344538702356814 ---> Yeah but during the event we were told that it will help us to gauge the performance of new components and this capability is new.

https://x.com/alpha_defense/status/1827346278046691645 ---> Which implies it was for TVC testing.

Re: Kaveri & Aero-Engine: News & Discussion

India, US to push co-production of GE engines for Tejas, Stryker combat vehicles

https://www.thehindubusinessline.com/ec ... 561703.ece

24 August 2024

https://www.thehindubusinessline.com/ec ... 561703.ece

24 August 2024

The two countries had earlier given a nod to a commercial agreement between General Electric (GE) Aerospace and defence PSU Hindustan Aeronautics Limited (HAL) to manufacture GE F-414 turbofan jet engines in India. As per the negotiations going on, the GE wants to keep the IPR with themselves.

Re: Kaveri & Aero-Engine: News & Discussion

I don't get it - was this the intent from the start that they should keep all the IPR? I thought it was the opposite, and that they'd transfer the tech to us so that we could make it all ourselves. Is your red highlight showing that they're reneging or pulling back from past understanding?Rakesh wrote: ↑26 Aug 2024 03:42 India, US to push co-production of GE engines for Tejas, Stryker combat vehicles

https://www.thehindubusinessline.com/ec ... 561703.ece

24 August 2024

The two countries had earlier given a nod to a commercial agreement between General Electric (GE) Aerospace and defence PSU Hindustan Aeronautics Limited (HAL) to manufacture GE F-414 turbofan jet engines in India. As per the negotiations going on, the GE wants to keep the IPR with themselves.

Re: Kaveri & Aero-Engine: News & Discussion

It was always the intention that GE was going to keep the IPR. Everyone knew this, especially in India. There is no incentive for GE to part with this. See this article below from last June. I don't see the point in why The Hindu is raking this issue up now.

US-India Landmark Jet Engine Deal Includes Unprecedented 80 Per Cent Tech Transfer By Value: Report

https://swarajyamag.com/defence/us-indi ... lue-report

17 June 2023

US-India Landmark Jet Engine Deal Includes Unprecedented 80 Per Cent Tech Transfer By Value: Report

https://swarajyamag.com/defence/us-indi ... lue-report

17 June 2023

During the upcoming state visit by Prime Minister Narendra Modi to the United States, India and the US are set to sign a deal for the co-production of General Electric's F414 fighter jet engine. According to a source quoted by CNBC-TV18, the agreement between GE and Hindustan Aeronautics Limited (HAL) will involve an impressive 80 per cent transfer of jet engine technology by value, marking a significant milestone in cooperation between the two countries. Currently, the negotiating teams from India and the United States are focusing on finalizing payment mechanisms, procurement of machinery, and modalities for technology transfer.

The transfer of technology will encompass several crucial aspects of GE jet engines. These include special coating for erosion and corrosion, repair technology for turbines, compression disc and blades, coating and machining of single crystal turbine blades, machining and coating of hot end parts, complete tech transfer for blisk machining, machining of powder metallurgy, polymer matrix composite, laser drilling for combustion, and bottle boring of shafts.

The US has not shared engine technology to this extent with any other nation. A source familiar with the deal stated, "This level of technology transfer has not been given by the US, the UK, and France to any country." The transfer of technology is expected to occur gradually, taking place in different phases over the next few years. Within a span of three years, it is anticipated that India will contribute 80 percent of the value added to the engine through this technology transfer process.

Re: Kaveri & Aero-Engine: News & Discussion

Wrt the highlighted part - Nah, on the contrary, most people have no clue actually ...Rakesh wrote: ↑26 Aug 2024 06:11 It was always the intention that GE was going to keep the IPR. Everyone knew this, especially in India. There is no incentive for GE to part with this. See this article below from last June. I don't see the point in why The Hindu is raking this issue up now.

US-India Landmark Jet Engine Deal Includes Unprecedented 80 Per Cent Tech Transfer By Value: Report

https://swarajyamag.com/defence/us-indi ... lue-report

17 June 2023

...

...

Somebody utters the term "ToT" and everybody starts thinking that OEMs will now start falling over themselves, to not only "transfer" the entire spectrum of not only 4th Gen Turbofan Mfg Technology, but also, almost as a corollary, the entire spectrum of 4th gen Turbofan D&D technologies.

DDM of course never had, and will never have, any clue wrt anything remotely related to technology etc, so to expect them to bring out these nuanced aspects etc, is well ...

For e.g., in the above mentioned Sarajyamag Article, see how cleverly the term "... coating and machining of single crystal turbine blades ..." has been casually thrown in.

I can bet, most will assume, after seeing the term "Single Crystal Turbine Blades", that post this ToT deal, India would have acquired 4th Gen SC Turbine blade manufacturing capability - in fact, some will even assume that, based on this hand-me-down ToT tech-transfer, India will now have acquired capability to design, develop and manufacture any-Gen SC Turbine Blades (for any application).

But while doing so, nobody even cared to think-thru/analyze/atleast-ask-around a simple set of questions:

a) For applying coating to a SC Turbine blade, one needs to first manufacture the Turbine blade itself, isn't it? So, will the technology towards the manufacture of these Turbine blades (to be coated indigenously) be also transferred?

b) If yes - will the SC metallurgy be also transferred - or is it the SC turbine raw material will require to be whole-sole imported in the ingot form (to be processed/manufactured to SC Turbine blade)?

c) If the answer to "b" above is yes,

i) What about the processing tech (specific to this usage) of say, just one of the alloying components, Rhenium. Will it have to be imported as well, or our existing technology would be enough (and, if yes, will OEM let us know the exact % and purity level etc to be used)?

This same question will be applicable for remaining 21-odd Superalloy components.

ii) Assuming OEM is then ok to share exact % (maybe down to 2-decimal points of accuracy) of the superalloy composition, is the OEM expecting us to import a particular model of VIM furnaces etc, with all it's configuration parameters hard-coded, to finally produce the superalloy ingot? Or will the OEM allow us to use our own existing VIM etc infra to produce the required ingots?

... so on and so forth.

Pls note that I have barely covered the 1st step, of 6-step processing (at an very very very high-level):

1) Raw Material processing – Ingot prep

2) Mold Production (hint: Alumina based vs Silica based core prep, at mass mfg levels)

3) Investment Casting

4) Heat Treatment

5) Coating/TBC and Laser Drilling

6) Testing (NDT etc)

This post will become too long if I continue to frame such questions for all of these 6 steps - in fact, 1st step is probably the easier one.

So that two word casual-mentioning (of "... coating and machining of single crystal turbine blades ...") means, most probably the mfg technology for first 4 steps above will be firmly with the OEM and OEM alone.

But, in absence of such level of analysis/thinking -thru, DDM, and thus aam-junta as well, will continue to hallucinate that oh-so-friendly OEM has handed over the Turbine Blade Mfg (and even D&D) Technology on a platter to us - something they themselves had spent tens of billions of $s and tens of decades of back-breaking R&D to develop that very same technological capability.

Anyway, now a few years later, after a series of half-truths by the PSU mgmt teams, with some high "indigenously developed %" figures thrown around quite liberally, an utterly false narrative, wrt indigenous TF D&D capability/maturity (entirely as a result of such so-called ToT-partnerships etc), is built up to the popular folklore level.

And then bang - when, almost inevitably, another similar TF D&D requirement comes up (or worse, Raw-material etc gets held up by the OeM), and then when it gets revealed the true nature of these so-called partnerships and ToTs, another round of mis-directed and ill-informed rudali and finger-pointing will start, inevitably pointing towards these very same PSUs (who doesn't care much about these hue-and-cry/criticisms any way).

So for the umpteenth time, this F414-INS6 ToT deal, is a true-blue ToAsT initiative, nothing more nothing less - 50%, 60%, 80% whatever-% ToT figures notwithstanding - calling it anything else is just that, utter balony.

And, except of building some testing infra (and testing expertise), expecting such ToAsT initiatives to add even an iota to indigenous TF D&D capability (or for that matter even mfg atmanirbharata), is building castles in air.

Some relevant posts, for further reading, can be:

Reg: F414 ToAsT Initiative - 1

Reg: F414 ToAsT Initiative - 2

Reg: F414 ToAsT Initiative - 3

...

...

Re: Kaveri & Aero-Engine: News & Discussion

Folks on the Indian negotiating team would have been aware of this from day one. I find it surprising that they walked into this, without being aware of that fact. If they were naïve enough to believe that they could convince the US side of handing over the IPR, then that is their fault. I don't expect the media to understand the difference, as you have indicated in your post. This is media sensationalism.

Re: Kaveri & Aero-Engine: News & Discussion

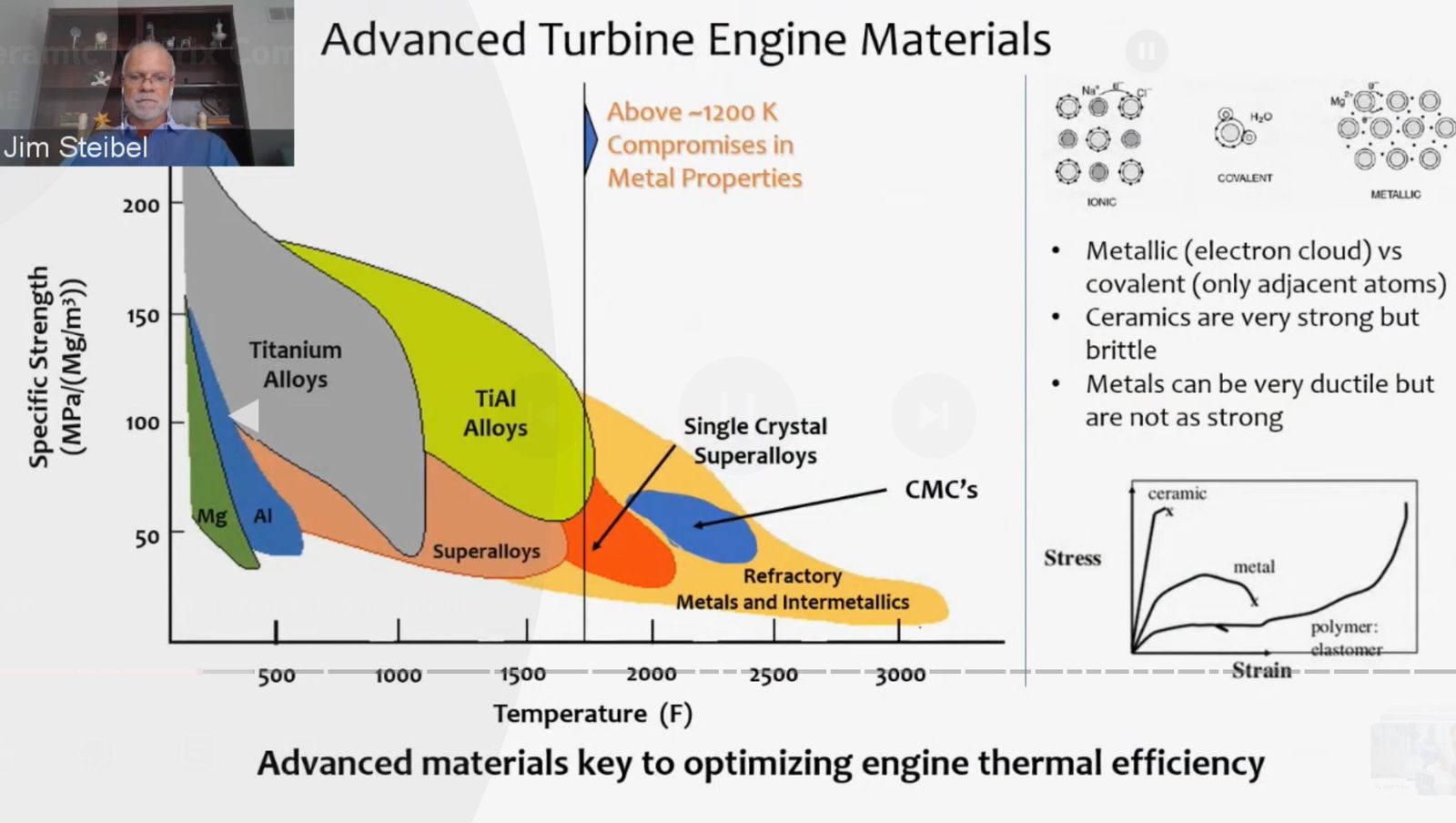

https://x.com/alpha_defense/status/1828385327880487271 ----> That line at center, GTRE has mastered everything on its left. That is our RD-33 and AL-31 category technology. On the right side, we have started using some technology like single crystal on the dry Kaveri. It will require money and time to do these things. At this moment GE is the only maker that has achieved CMC maturity of that level. But only if WE INVEST or its basically depending on an unreliable engine maker.

Re: Kaveri & Aero-Engine: News & Discussion

Even if Kaveri engine is under-powered for single-engine aircraft, can it be used for a twin-engined aircraft?

Can we some how get to MVP? ("Minimum Viable Product")

Can we some how get to MVP? ("Minimum Viable Product")

Re: Kaveri & Aero-Engine: News & Discussion

We can go for a 4-engine bomber UCAV; a Ghatak+++ with kaveri

Or a lighter Loyal Wingman version of Tejas by reducing the weight from pilot and his support systems. Needless to say it will come with its share of redesign and certification workload.

The engine is useful for quite many use cases, and continuing on it would bring a whole ecosystem of gas turbine capabilities. That it hasn't been used for some viable aircraft is just a sign of our failures in defence planning.

That being said, there is approval and work underway to integrate it with Tejas. So we will slowly see it evolve and be used for multiple projects where it fits the role.

Or a lighter Loyal Wingman version of Tejas by reducing the weight from pilot and his support systems. Needless to say it will come with its share of redesign and certification workload.

The engine is useful for quite many use cases, and continuing on it would bring a whole ecosystem of gas turbine capabilities. That it hasn't been used for some viable aircraft is just a sign of our failures in defence planning.

That being said, there is approval and work underway to integrate it with Tejas. So we will slowly see it evolve and be used for multiple projects where it fits the role.

Re: Kaveri & Aero-Engine: News & Discussion

RElevant for the thread

https://www.zeebiz.com/companies/news-t ... ngs-299039

PTC Industries develops technology for manufacturing of single crystal directionally solidified castings

they would supply safran

[ Safran and PTC Industries sign contract to provide casting parts for the LEAP engine powering single-aisle jet. https://www.safran-group.com/pressroom/ ... 2023-11-13

https://www.zeebiz.com/companies/news-t ... ngs-299039

PTC Industries develops technology for manufacturing of single crystal directionally solidified castings

they would supply safran

[ Safran and PTC Industries sign contract to provide casting parts for the LEAP engine powering single-aisle jet. https://www.safran-group.com/pressroom/ ... 2023-11-13

Last edited by drnayar on 08 Sep 2024 21:36, edited 1 time in total.

Re: Kaveri & Aero-Engine: News & Discussion

More here

Not clear what the Safran connection is here, but this looks pretty advanced tech that would be useful for any engine effort.This capability and its related infrastructure will enable the company to produce Airfoils (blades and vanes) with complex internal hollow cooling passages while having highly specialized microstructures like Single Crystal or Directionally Solidified.

Re: Kaveri & Aero-Engine: News & Discussion

Well, without details like which SC Gen, Cooling effectiveness (i.e. the cooling architecture employed) and, most importantly, production rate (of say Number of blades/vanes per month etc), purely tech capability wise, this is something that has been achieved approx 1.5+ decades back, indigenously.vera_k wrote: ↑07 Sep 2024 22:13 More here

Not clear what the Safran connection is here, but this looks pretty advanced tech that would be useful for any engine effort.This capability and its related infrastructure will enable the company to produce Airfoils (blades and vanes) with complex internal hollow cooling passages while having highly specialized microstructures like Single Crystal or Directionally Solidified.

for e.g.

SC Gen - 4th Gen

Cooling effectiveness - 250+ deg C diff

Also very important is to understand, if this capability includes building/manufacturing the applicable ceramic cores (as opposed to importing them from the OEM and placing them in the mold) at a mass-manufacturing level.

What is also important, to understand, if the post-build technological aspects like Post casting heat-treatment (parameters of which are normally closely-guarded secret by the OEM), Machining of the raw blades, Coating (both Env and TBC) and Laser Drilling (for the film-cooling aspects) etc, are also part of this achieved mass-manufacturing capability - ofcourse, these steps can be optional, as the OEM may want to keep these steps to themselves (IPR protection).

And of course, almost invariably, the OEM would want to keep the SC raw material production part to themselves - i.e. the vendor will be supplied the SC ingots, to then manufacture the blades/vanes from it.

It can very well be, that the OEM supplies the SC raw material ingots and the casting molds as well, and the vendor does purely the investment casting part - even then, that capability in itself is nothing to scoff at, between!!

Just that it's a single step in the 6-step HPT/LPT Blade/Vane mass-mfg capability ...

But, having said all that, coming from a private sector entity, this is indeed a fantastic news - this is exactly how Turbofan manufacturing ecosystems are built, brick by brick.

Re: Kaveri & Aero-Engine: News & Discussion

FYI, June, 2024. 2 page pdf. Bharatiya company develops SCB

“PTC Industries develops Technology and Capability for Manufacturing of Single Crystal and Directionally Solidified Castings

“PTC Industries develops Technology and Capability for Manufacturing of Single Crystal and Directionally Solidified Castings

Re: Kaveri & Aero-Engine: News & Discussion

Chinese model for engine development