Source : https://x.com/amitmalviya/status/190728 ... XrvXw&s=19

Not sure of authenticity..

This is the last reported news on Kaveri...drnayar wrote: ↑02 Apr 2025 20:33

Source : https://x.com/amitmalviya/status/190728 ... XrvXw&s=19

Not sure of authenticity..

Must be - though I think they are CMSX4 (2nd Gen SX) based, which in turn would mean ~1075-90 deg C raw-metal-temp capability.

April Foolsdrnayar wrote: ↑02 Apr 2025 20:33

Source : https://x.com/amitmalviya/status/190728 ... XrvXw&s=19

Not sure of authenticity..

Bhai, I met one of the directors of HTFE during 2020 DefExpo.maitya wrote: ↑03 Apr 2025 12:32Must be - though I think they are CMSX4 (2nd Gen SX) based, which in turn would mean ~1075-90 deg C raw-metal-temp capability.

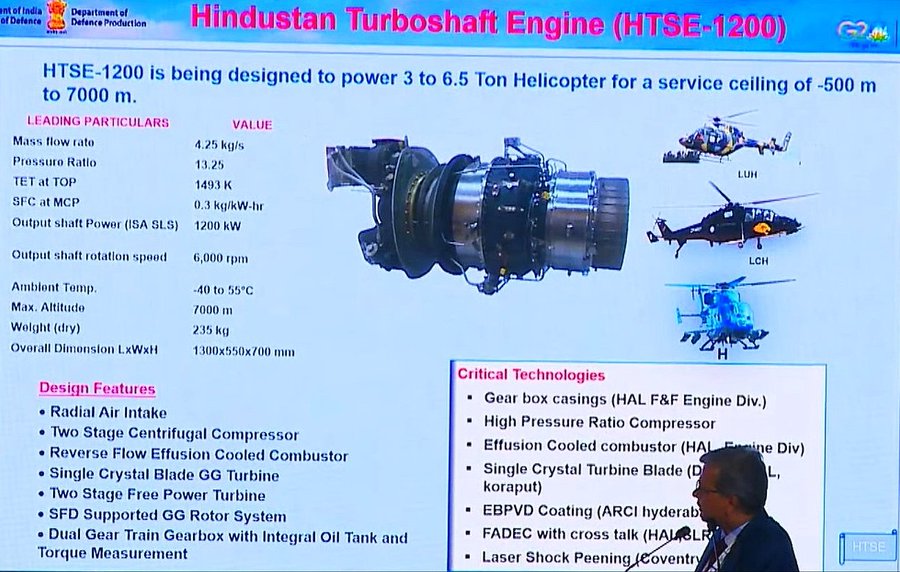

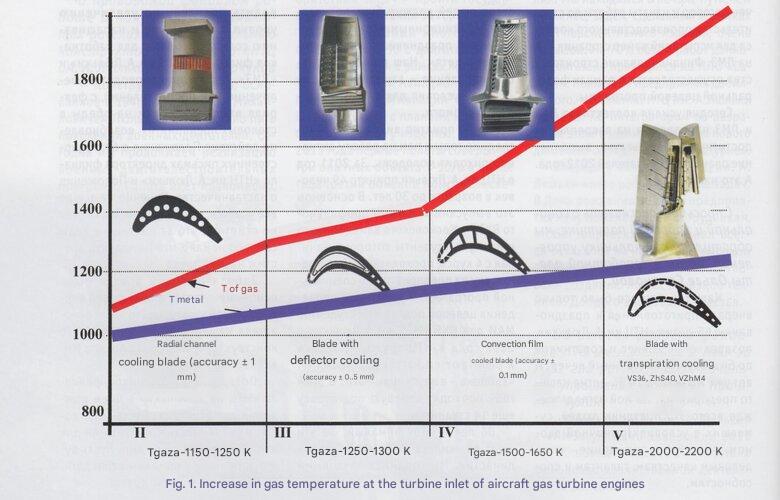

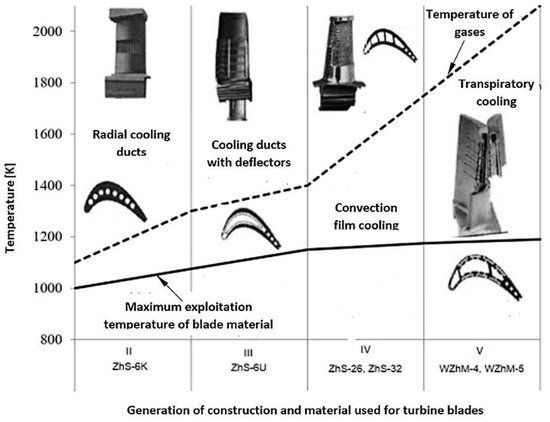

But do note 1493deg K (1220deg C) TeT, is way too low for a SX-based blades that employs both, film-cooling* (~250deg C adv) and also with TBC (~150deg C adv) - ofcourse, that also doesn't mean absence of internal blade-cooling architecture etc.

Contrast it with HAL developed In718 (so poly-crystalline) based 3D printed cooled blades (and NGVs), for HTFE, that supports 1455deg K.

Similarly the SX blades (equiv to 2nd Gen, roughly) of AL-31F, support TeT 1390deg C TeT ... so must be of same genre.

Rhenium is normally added to Single-Crystal Ni-Superalloys (2nd gen onwards) to enhance its creep resistance.VishnuS wrote: ↑04 Apr 2025 11:05Bhai, I met one of the directors of HTFE during 2020 DefExpo.maitya wrote: ↑03 Apr 2025 12:32

Must be - though I think they are CMSX4 (2nd Gen SX) based, which in turn would mean ~1075-90 deg C raw-metal-temp capability.

But do note 1493deg K (1220deg C) TeT, is way too low for a SX-based blades that employs both, film-cooling* (~250deg C adv) and also with TBC (~150deg C adv) - ofcourse, that also doesn't mean absence of internal blade-cooling architecture etc.

Contrast it with HAL developed In718 (so poly-crystalline) based 3D printed cooled blades (and NGVs), for HTFE, that supports 1455deg K.

Similarly the SX blades (equiv to 2nd Gen, roughly) of AL-31F, support TeT 1390deg C TeT ... so must be of same genre.

He had a long conversation, I couldn't find the audio clip of that conversation. But one thing I clearly remember was that Hot section of HTFE doesn't have any Rehenium. He said it is not possible to add Re as the 3D printing doesn't allow this. The plan was to maintain temp by using cooling channels and that was the primary reason for choosing 3D printing.

Our conversation revolved mostly around 3D printing.

You probably knew this and maybe more about the alloy too. Just thought of sharing with you here.

VishnuS wrote: ↑04 Apr 2025 11:05Bhai, I met one of the directors of HTFE during 2020 DefExpo.maitya wrote: ↑03 Apr 2025 12:32

Must be - though I think they are CMSX4 (2nd Gen SX) based, which in turn would mean ~1075-90 deg C raw-metal-temp capability.

But do note 1493deg K (1220deg C) TeT, is way too low for a SX-based blades that employs both, film-cooling* (~250deg C adv) and also with TBC (~150deg C adv) - ofcourse, that also doesn't mean absence of internal blade-cooling architecture etc.

Contrast it with HAL developed In718 (so poly-crystalline) based 3D printed cooled blades (and NGVs), for HTFE, that supports 1455deg K.

Similarly the SX blades (equiv to 2nd Gen, roughly) of AL-31F, support TeT 1390deg C TeT ... so must be of same genre.

He had a long conversation, I couldn't find the audio clip of that conversation. But one thing I clearly remember was that Hot section of HTFE doesn't have any Rehenium. He said it is not possible to add Re as the 3D printing doesn't allow this. The plan was to maintain temp by using cooling channels and that was the primary reason for choosing 3D printing.

Our conversation revolved mostly around 3D printing.

You probably knew this and maybe more about the alloy too. Just thought of sharing with you here.

I heard this news as 82 kN.habal wrote: ↑06 Apr 2025 08:49 apparently latest batch of 16 kaveri engines (not derivative) has generated 102 kn thrust in high altitude tests in Russia. No news on printed media confirms this but flurry of youtube vids like this.

the 16 kaveri engines sent to russia included the kaveri 2.0 as well, and this was a highly guarded detail not unveiled until tests were completed and engines recd back in India.

Bhai, I haven't been to AI or DefExpo since 2021.Cybaru wrote: ↑05 Apr 2025 00:48VishnuS wrote: ↑04 Apr 2025 11:05

Bhai, I met one of the directors of HTFE during 2020 DefExpo.

He had a long conversation, I couldn't find the audio clip of that conversation. But one thing I clearly remember was that Hot section of HTFE doesn't have any Rehenium. He said it is not possible to add Re as the 3D printing doesn't allow this. The plan was to maintain temp by using cooling channels and that was the primary reason for choosing 3D printing.

Our conversation revolved mostly around 3D printing.

You probably knew this and maybe more about the alloy too. Just thought of sharing with you here.

Any timelines of when the first ground test begins for this engine? Also didnt they have a HTFE 2000 in works?

this is a different engine, 140 kN max thrust is targeted and whether it achieved that or not is not clear but 102 kN dry thrust was achieved in Russia high altitude tests while engine dry thrust target was previously at 90 kN. From my open source reading this engine is not Kaveri without afterburner called KDE but another variant rated for 90 kN which exceeded expectations during Russian high altitude tests. Some sources have given this name as ganga which is an engine developed for AMCA.VishnuS wrote: ↑06 Apr 2025 17:51I heard this news as 82 kN.habal wrote: ↑06 Apr 2025 08:49 apparently latest batch of 16 kaveri engines (not derivative) has generated 102 kn thrust in high altitude tests in Russia. No news on printed media confirms this but flurry of youtube vids like this.

the 16 kaveri engines sent to russia included the kaveri 2.0 as well, and this was a highly guarded detail not unveiled until tests were completed and engines recd back in India.

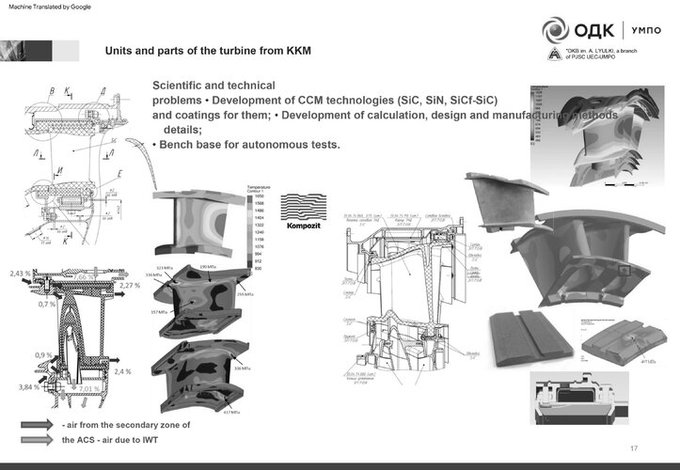

In this context, further details from@shreedharsingh9 in X: Russia's advancements wrt CMC Turbine Bladesmaitya wrote: ↑01 Apr 2025 12:12 From X - @shreedharsingh9:

Jet Engine parts made from CMC materials

Nothing in this article that we haven't discussed, in great details, before ...Kailash wrote: ↑28 Apr 2025 10:02 was this posted earlier - https://alphadefense.in/index.php/2025/04/13/key-improvements-in-the-kaveri-engine-by-gtre/

Talks a lot about weight reduction. Blisks for LPC/HPC stages, PMC ducts. Also talks of CMSX-4/TBC usage contributing to slight increases in TeT

The third bullet viz. "Attracting foreign OEMs with co-dev & tech transfer", is completely oxymoronic - other 3 ofcourse are fine.Rakesh wrote: ↑01 May 2025 16:22 https://x.com/ShiroBarks/status/1917809748549984406 ---> “Our skies must be powered by engines built in India, for India.”

• Fast-tracking the Kaveri

• Boosting public-private R&D partnerships

• Attracting foreign OEMs with co-dev & tech transfer

• Developing materials & testing for high-thrust propulsion

India prioritises homegrown aero-engine development after Pahalgam attack

https://english.mathrubhumi.com/news/in ... e-193bdc6d

24 April 2025