Kaveri & Aero-Engine: News & Discussion

Re: Kaveri & Aero-Engine: News & Discussion

Just wanted to provide another perspective. Most of the Russian engines that are made in India for Su-30MKI and RD-33 engines, HAL has a good idea on the engine details. Only the critical parts for an engine are supplied by Russia, the rest of the stuff HAL produces. IOW India knows where the critical stuff R&D is required.

The current MOD babucracy has only given approval for the Kaveri line of R&D. The Russian engines require special permissions from Russia to tinker with. BTW who is going to test the tinkering? Russia has the test setups but India lacks them. Having parallel efforts requires more R&D funds which is hard to obtain. I would continue to get the Kaveri tested and certified (even it is slightly less performant in specs). This phase takes time and hopefully things go well. Things like ghatak for 1st deployment of the Kaveri makes sense but does ghatak need to undergo massive changes to accommodate the Kaveri. Nothing like getting your own engine working and qualified. All the rest have huge risks, agreements, testing, etc., and also there is no such thing as total TOT!

The current MOD babucracy has only given approval for the Kaveri line of R&D. The Russian engines require special permissions from Russia to tinker with. BTW who is going to test the tinkering? Russia has the test setups but India lacks them. Having parallel efforts requires more R&D funds which is hard to obtain. I would continue to get the Kaveri tested and certified (even it is slightly less performant in specs). This phase takes time and hopefully things go well. Things like ghatak for 1st deployment of the Kaveri makes sense but does ghatak need to undergo massive changes to accommodate the Kaveri. Nothing like getting your own engine working and qualified. All the rest have huge risks, agreements, testing, etc., and also there is no such thing as total TOT!

Re: Kaveri & Aero-Engine: News & Discussion

Agree. It would be interesting to think if we are not asking the western engine manufacturers and getting the same deal as we have had with the Russian engines ?!.. no tech for hot section etc !!bala wrote: ↑11 Mar 2025 23:28 Just wanted to provide another perspective. Most of the Russian engines that are made in India for Su-30MKI and RD-33 engines, HAL has a good idea on the engine details. Only the critical parts for an engine are supplied by Russia, the rest of the stuff HAL produces. IOW India knows where the critical stuff R&D is required.

The current MOD babucracy has only given approval for the Kaveri line of R&D. The Russian engines require special permissions from Russia to tinker with. BTW who is going to test the tinkering? Russia has the test setups but India lacks them. Having parallel efforts requires more R&D funds which is hard to obtain. I would continue to get the Kaveri tested and certified (even it is slightly less performant in specs). This phase takes time and hopefully things go well. Things like ghatak for 1st deployment of the Kaveri makes sense but does ghatak need to undergo massive changes to accommodate the Kaveri. Nothing like getting your own engine working and qualified. All the rest have huge risks, agreements, testing, etc., and also there is no such thing as total TOT!

wont it be better to get back to the /Russians for the critical tech they had not shared so far ., even if one gen behind and build up from there ?

Re: Kaveri & Aero-Engine: News & Discussion

Maitya ji, I have a question... I remember reading a rumor that we had Al 31 engine shortage during late 22 and early 23s. We had used our knowledge gained on Kaveri to manufacture spare parts.

I am not sure whether this is true or not, but can't we use this at least to improve the quality of RD - 33s we are using our MiG 29s? Its MBTO is a major issue...

I am sure someone might have asked you this question and you might have answered... Sorry to ask you once again. I really love your long and detail oriented posts.

Re: Kaveri & Aero-Engine: News & Discussion

Well, let me just say this: Since the so-called "manufacturing from raw materials" were resulting in abominably-poor MTBO and MTBF figures, and since in our furrin-mai-baap-who-can-do-no-wrong psyche meant all must be HAL's fault type of witch-hunt, GTRE/DMRL/HAL et all, worked diligently on the component manufacturing technologies, to fantastically improve these (MTBO/MTBF) figures - part by part!!VishnuS wrote: ↑12 Mar 2025 11:15Maitya ji, I have a question... I remember reading a rumor that we had Al 31 engine shortage during late 22 and early 23s. We had used our knowledge gained on Kaveri to manufacture spare parts.

I am not sure whether this is true or not, but can't we use this at least to improve the quality of RD - 33s we are using our MiG 29s? Its MBTO is a major issue...

I am sure someone might have asked you this question and you might have answered... Sorry to ask you once again. I really love your long and detail oriented posts.

A ultra-crude analogy maybe, is wrt what was done wrt F414-EDE program vis-a-vis the EPE program ... remember, for every glamorous EPE program, there's also largely-not-talked about programs like EDE etc. If you read thru the genesis of these 2 programs, you'll appreciate this analogy better.

Yes, without painstakingly developed TF D&D and manufacturing maturity, from the Kaveri program, none of this would have been possible, though.

In fact, there's a large body of lament by HAL mgmt, that despite we having >100% wherewithal to graduate to a true-manufacture-from-raw-material and true-100%-indigenous-manufacturing ability of the entire AL-31FP, we can't even attempt those, due to contractual restrictions (of mandatory import clauses) that our MoD geniuses had "successfully" negotiated with mother Russia, a couple of decades back.

Remember, except maybe the mechanical 3-D vectoring tech, there's absolutely nothing in AL-31FP that has not already mastered by us decades back, via our indigenous TF programs ... and in fact except for Izdeliya-30, there's nothing that we need to learn from Russia wrt TF technology.

Let me stop here ...

Re: Kaveri & Aero-Engine: News & Discussion

https://x.com/ShiroBarks/status/1897674097250721845 ---> By 2030, we’ll be spending $170 billion on importing airliners with no return on that investment. The cost to manufacture an engine is no more than $10 billion, & adding another $10 billion for the airliner itself would still make it a highly profitable investment.

Re: Kaveri & Aero-Engine: News & Discussion

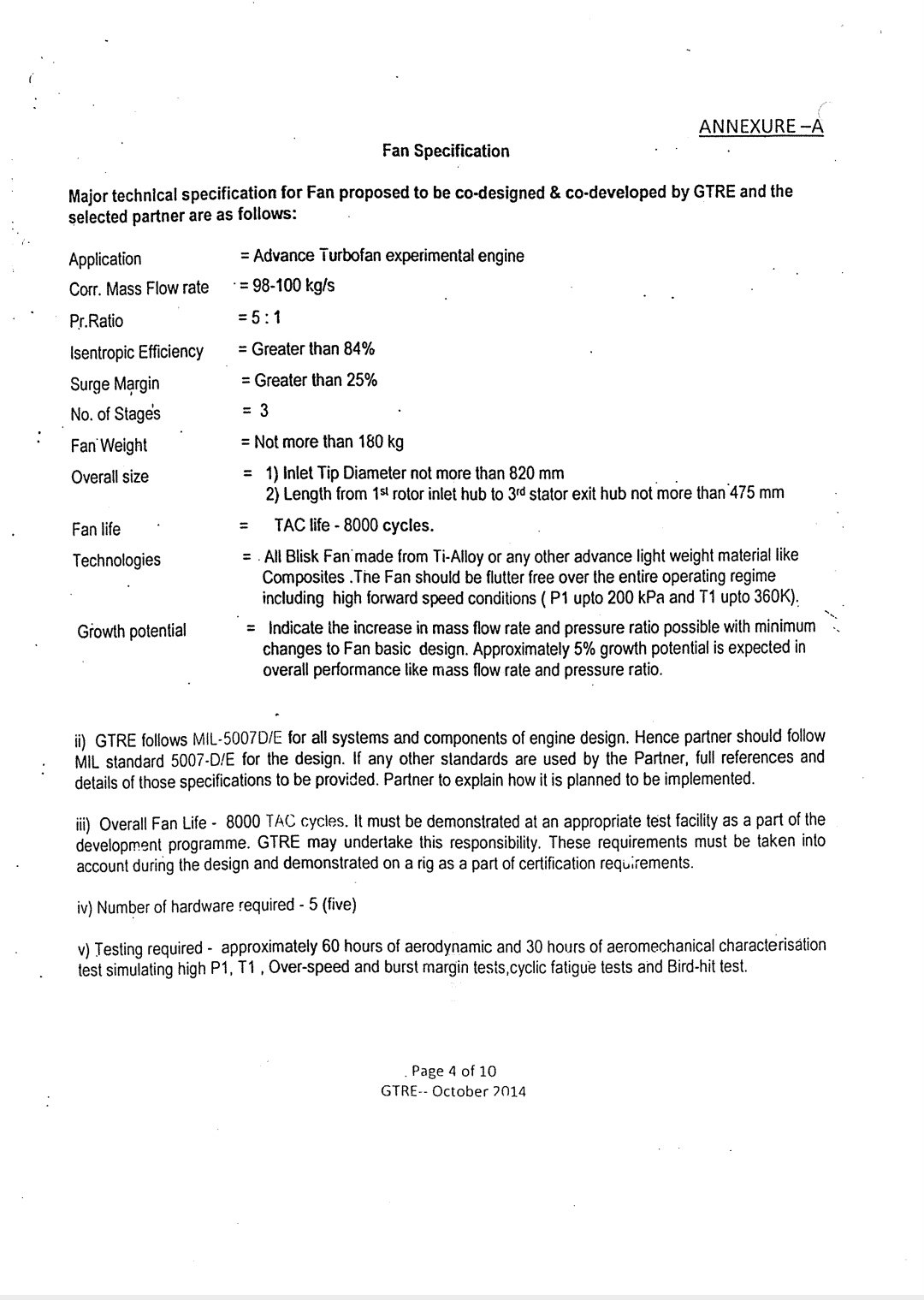

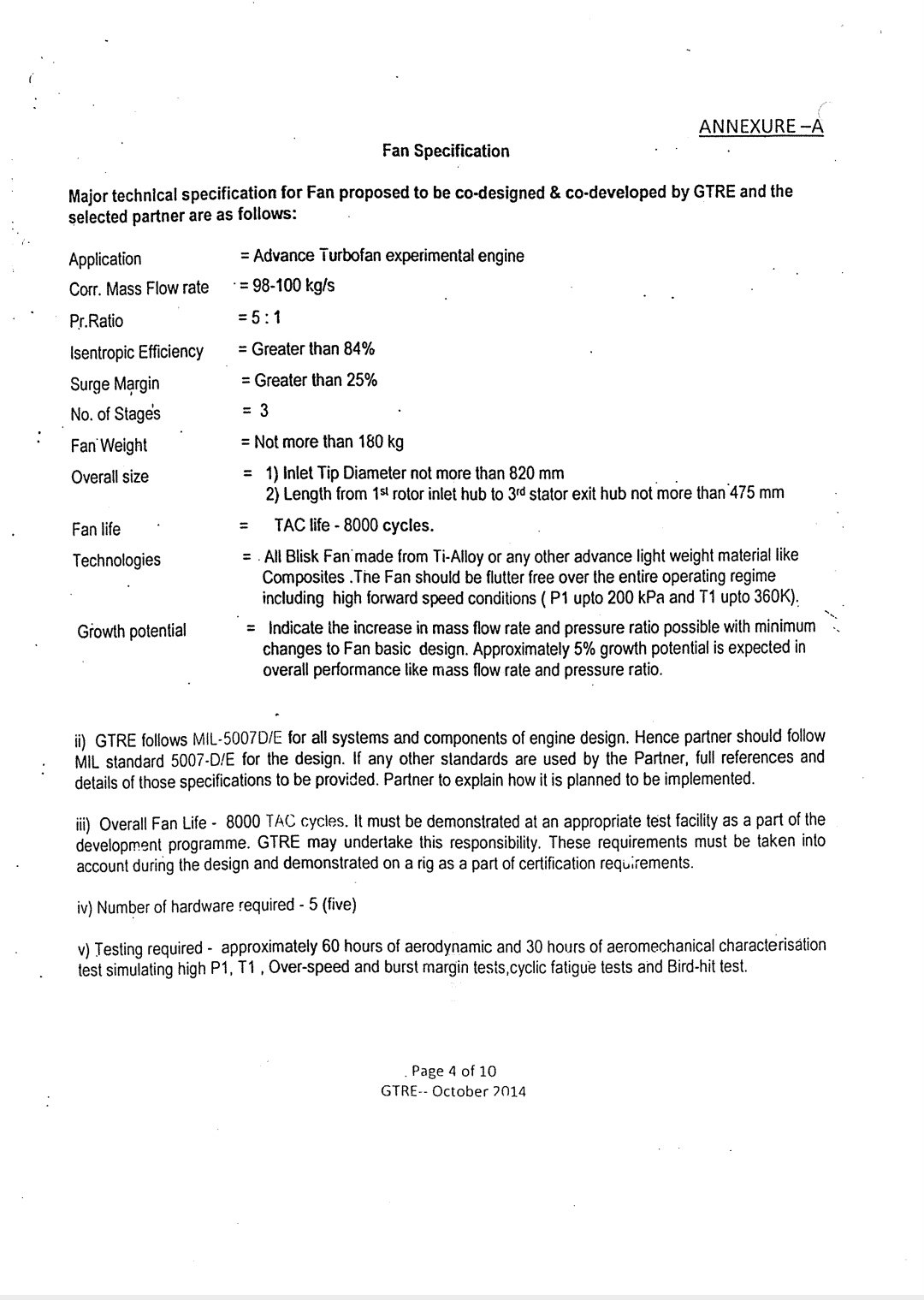

https://x.com/shreedharsingh9/status/18 ... 0914831746 ---> New fan for Kaveri and its specifications.

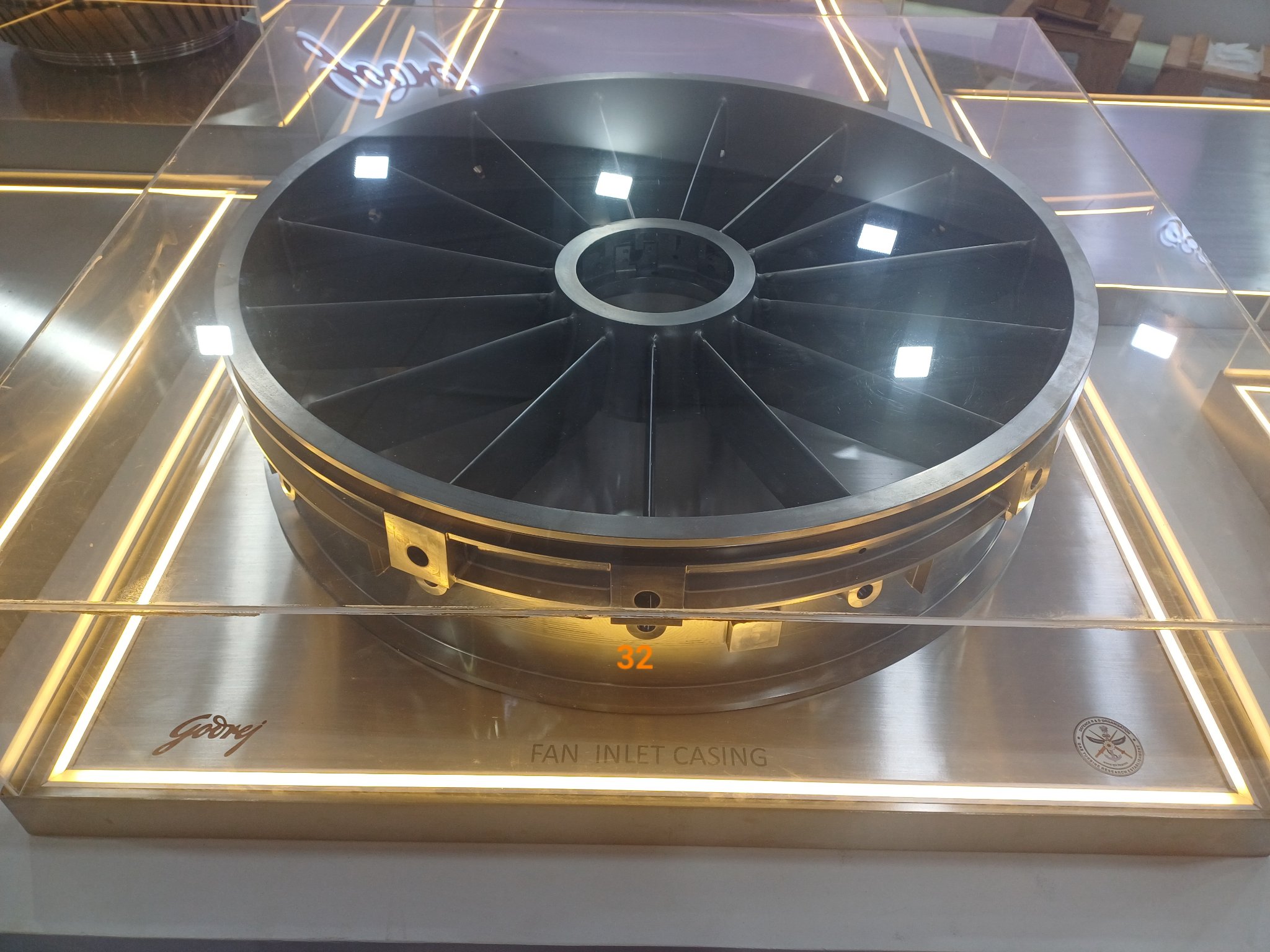

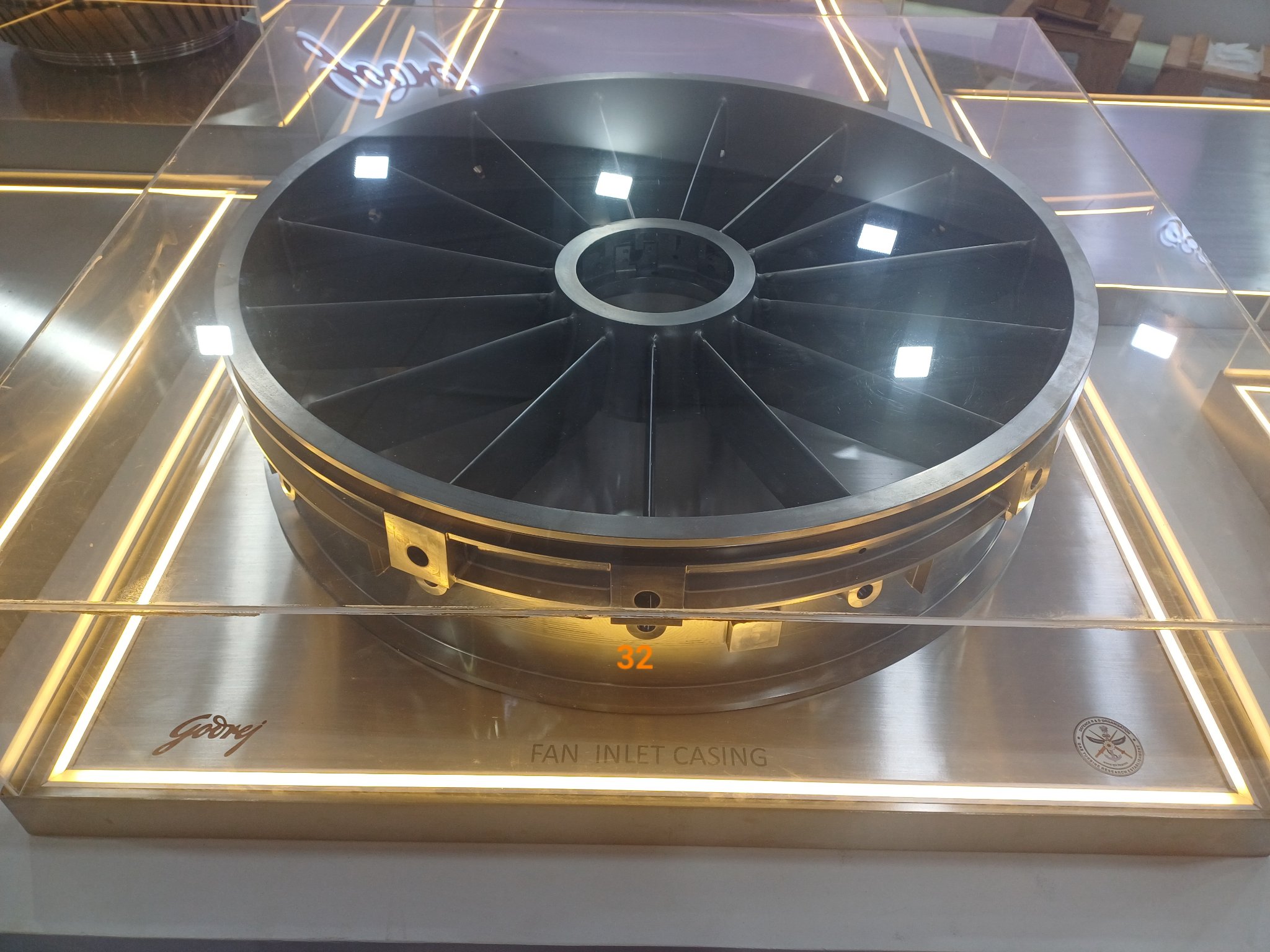

https://x.com/shreedharsingh9/status/18 ... 3139820687 ---> Fan Inlet Casing of GTRE Kaveri by Godrej.

https://x.com/shreedharsingh9/status/18 ... 3139820687 ---> Fan Inlet Casing of GTRE Kaveri by Godrej.

Re: Kaveri & Aero-Engine: News & Discussion

Last year there was close to half billion each invested in RD-33 and AL-31 program. The details are missing, with some snippets coming out. We are making 240 AL 31F engines and x amount of rd-33. Are these deals where we replace more parts indigenously? Can we have one more contract where we get the right to modify the engine (a la ws-10 and another for rd-33). Pay the amount (chinese successfully negotiated them 20 years ago) and go that route. It is not the only route. Effectively we will have three programs, two of these overlapping and perhaps complementing each other. RD-33/AL 31 engines gradually substituted with superalloys developed for Kaveri. The engine gets tested in Mig 29/SU30MKI after being thoroughly tested on the ground. You replace one part at a time. The investment overlap as far as superalloys and machining is there with Kaveri. Then you have Kaveri engine, whose superalloys are getting tested and used in RD-33/AL-31, while Kaveri goes through its own trial and tribulation. The third is the F414/SAFRAN/RR route, whoever gives us the tech. I will not count Lic manufacturing of f414 for Tejas mk2 in the same league, it is no different than AL31 lic manufacturing deal we got 2 decades back, only that it is few generation ahead of the AL31 tech, but ultimately it does not provide us either the flexibility or the ToT to build and export our own engines.

Re: Kaveri & Aero-Engine: News & Discussion

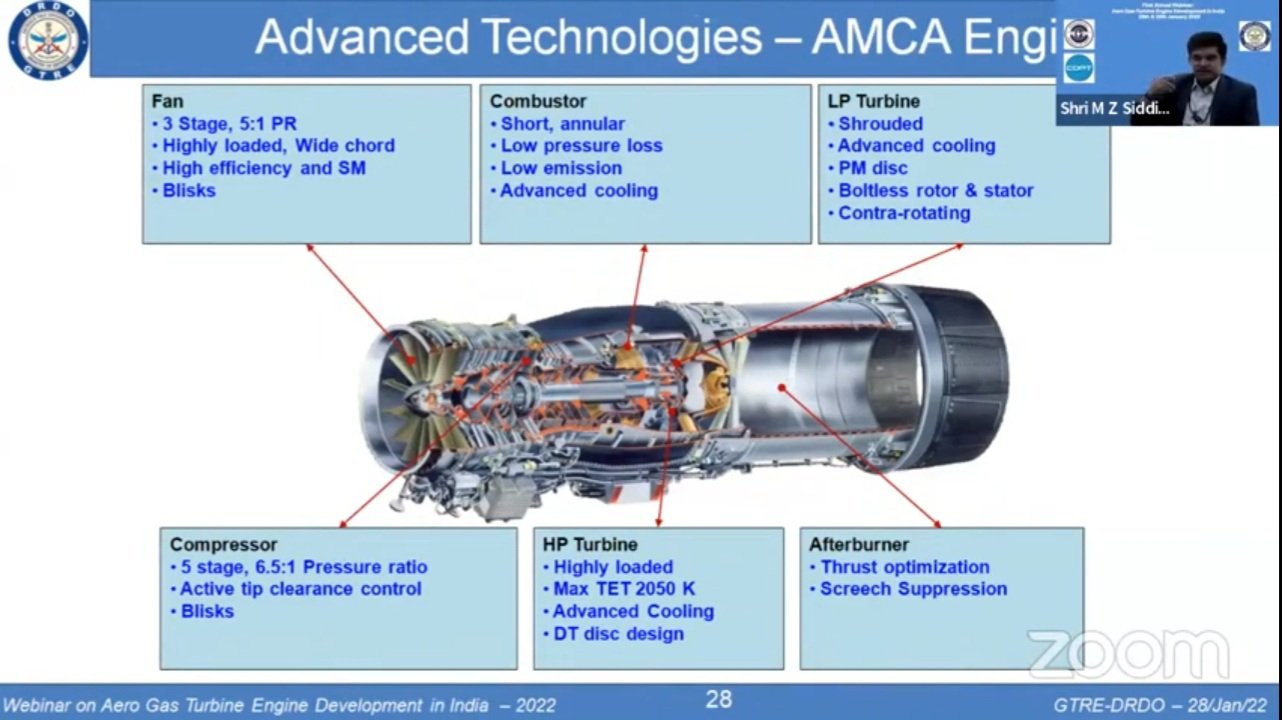

Small correction, pls note this is NOT for K9 or KDE ... the specifications (both inlet-mass-flow and Fan PR) are for a 5-gen TF with a much larger inlet geometry (may be for AMCA).Rakesh wrote: ↑12 Mar 2025 21:31 https://x.com/shreedharsingh9/status/18 ... 0914831746 ---> New fan for Kaveri and its specifications.

...

Pls refer to this old post from Indranil for context.

Re: Kaveri & Aero-Engine: News & Discussion

Russia’s Tit for Tat to F-35 Offer. Offers the most powerful AL-41 Engine from Su-57 Fighter Jet to India for the Su-30 MKI

Russia offers Sukhoi-57 engine for India’s Sukhoi-30MKI upgrade

https://www.tribuneindia.com/news/india ... i-upgrade/

12 Feb 2025

Russia offers Sukhoi-57 engine for India’s Sukhoi-30MKI upgrade

https://www.tribuneindia.com/news/india ... i-upgrade/

12 Feb 2025

The IAF operates 272 Sukhoi-30MKI jets — the largest fleet of any aircraft type — and is in negotiations with Russia for a comprehensive upgrade

In a significant development, Russia has offered India the engine that powers its latest stealth fighter jet, the Sukhoi-57, for the upgrade programme of the existing Sukhoi-30MKI fleet.

The Indian Air Force (IAF) operates 272 Sukhoi-30MKI jets — the largest fleet of any aircraft type — and is in negotiations with Russia for a comprehensive upgrade.

On Tuesday, Vadim Badekha, Chief Executive Officer of Russian aircraft manufacturer United Aircraft Corporation, said the Sukhoi-57 is powered by the AL-41 engine. “We are offering the new engine as part of the Sukhoi-30 upgrade to India,” Badekha stated while speaking to media persons at Aero India.

Currently, the Sukhoi-30MKI is powered by the AL-31 engine, which is less powerful than the AL-41 used in the Sukhoi-57 stealth jet. Russia’s proposal includes replacing the existing engines with the more advanced AL-41.[/b]

Re: Kaveri & Aero-Engine: News & Discussion

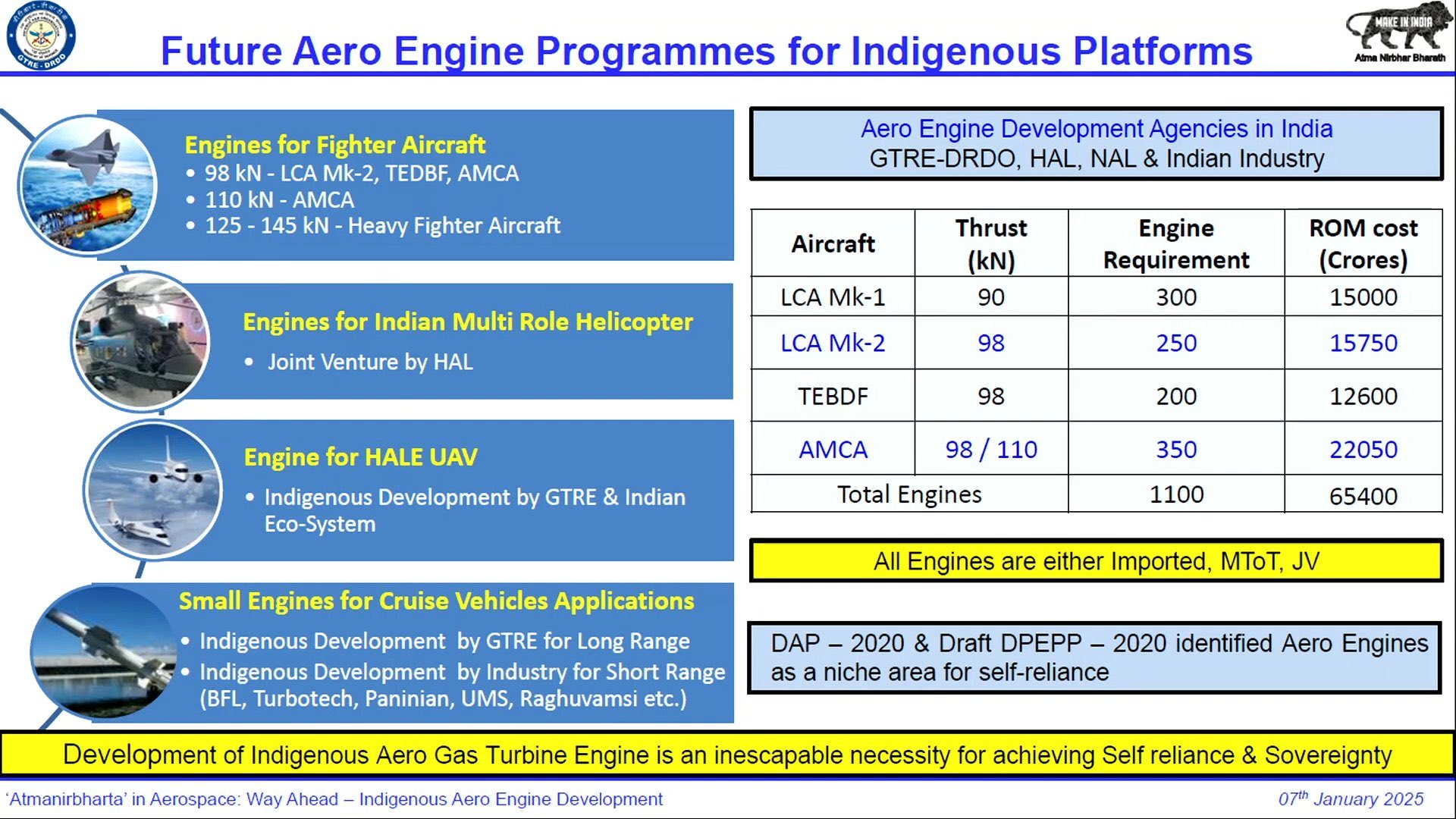

What this thing says is that Kaveri and follow on was never shelved. The doc is from 2014, 11 years ago!! They were thinking about engine for AMCA. It may not have gotten the fund that it needed, but never shut down. We may not be in such a bad state after all. It just need a little bid of more imagination, a little bit of risk taking and I guess most importantly IAF whole hearted involvement.maitya wrote: ↑12 Mar 2025 21:47Small correction, pls note this is NOT for K9 or KDE ... the specifications (both inlet-mass-flow and Fan PR) are for a 5-gen TF with a much larger inlet geometry (may be for AMCA).Rakesh wrote: ↑12 Mar 2025 21:31 https://x.com/shreedharsingh9/status/18 ... 0914831746 ---> New fan for Kaveri and its specifications.

...

Pls refer to this old post from Indranil for context.

Re: Kaveri & Aero-Engine: News & Discussion

Very informative thread on X about Kaveri story so far.

https://x.com/ShiroBarks/status/1899837 ... bwhsw&s=19

https://x.com/ShiroBarks/status/1899837 ... bwhsw&s=19

Re: Kaveri & Aero-Engine: News & Discussion

A word of caution: The veritable alphabet-soup that Russian modern TF designations are, it's easy to get confused what is actually being offered etc.chetak wrote: ↑12 Mar 2025 22:18 Russia’s Tit for Tat to F-35 Offer. Offers the most powerful AL-41 Engine from Su-57 Fighter Jet to India for the Su-30 MKI

Russia offers Sukhoi-57 engine for India’s Sukhoi-30MKI upgrade

https://www.tribuneindia.com/news/india ... i-upgrade/

12 Feb 2025

The IAF operates 272 Sukhoi-30MKI jets — the largest fleet of any aircraft type — and is in negotiations with Russia for a comprehensive upgrade

In a significant development, Russia has offered India the engine that powers its latest stealth fighter jet, the Sukhoi-57, for the upgrade programme of the existing Sukhoi-30MKI fleet.

The Indian Air Force (IAF) operates 272 Sukhoi-30MKI jets — the largest fleet of any aircraft type — and is in negotiations with Russia for a comprehensive upgrade.

On Tuesday, Vadim Badekha, Chief Executive Officer of Russian aircraft manufacturer United Aircraft Corporation, said the Sukhoi-57 is powered by the AL-41 engine. “We are offering the new engine as part of the Sukhoi-30 upgrade to India,” Badekha stated while speaking to media persons at Aero India.

Currently, the Sukhoi-30MKI is powered by the AL-31 engine, which is less powerful than the AL-41 used in the Sukhoi-57 stealth jet. Russia’s proposal includes replacing the existing engines with the more advanced AL-41.[/b]

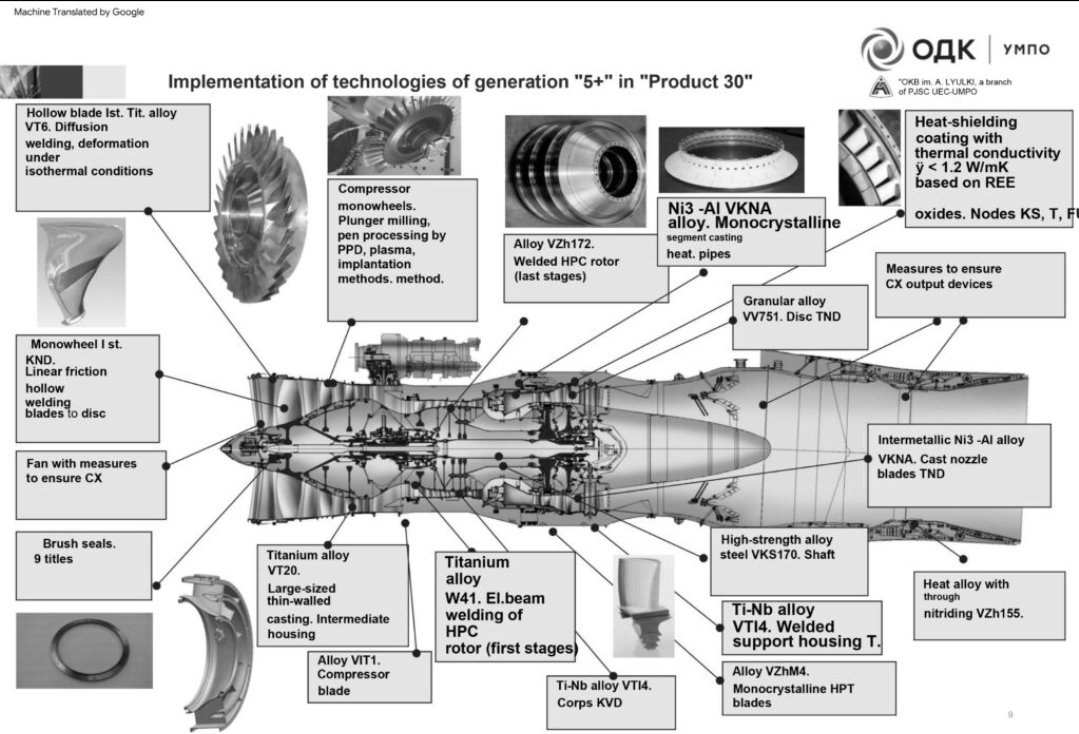

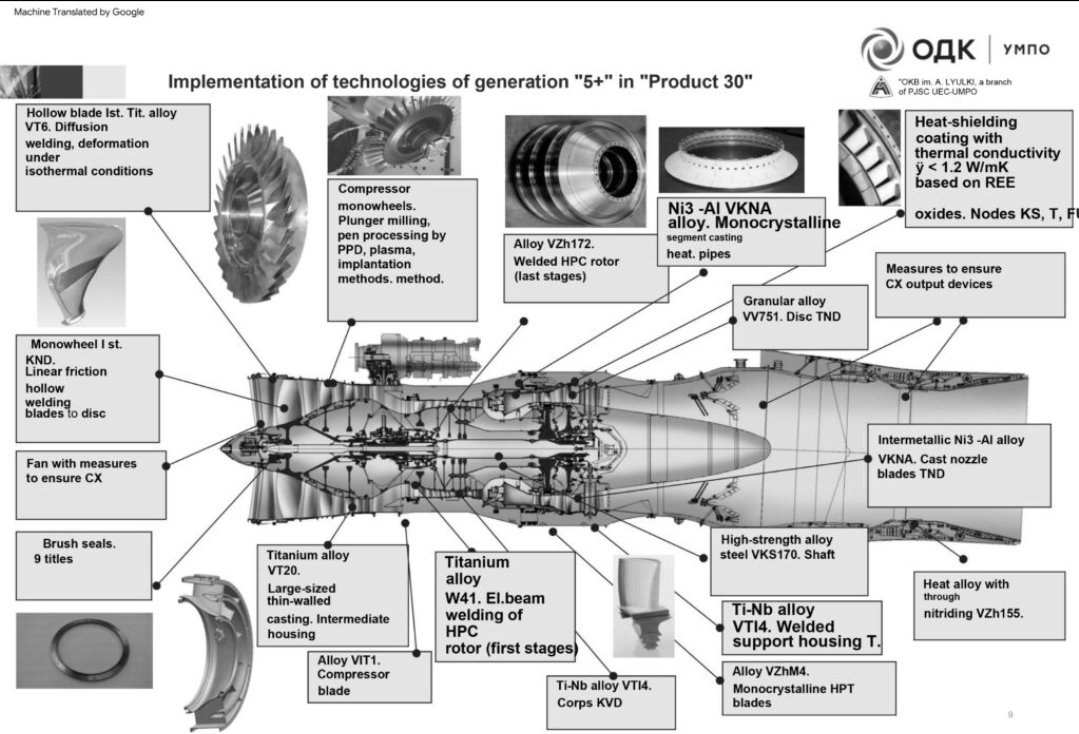

First of all there's no such thing as AL-41 etc anymore - however what is there is:

AL-41F (Izdeliya 20) - The variable cycle attempt from the 90s - which has since been abandoned.

AL-41-F1 (Izdeliya 117) - Heavily upgraded version of AL-31, currently used in Su-57 - no relation/lineage to the AL-41F

AL-41-F1S (Izdeliya 117S) - Slightly simpler version of AL-41F1

And then there's the big daddy, Izdelya-30/AL-51, which is a true-blue 5th Gen TF.

I think we have made it quite clear, on multiple occasions before, that AL-41-F1 etc, doesn't suit us.

We are rather better off, by getting a blanket permission to "improve" AL-31FP, indigenously, part-by-part (especially the Core) - which can result in an, say, AL-31FP-MKI.

This permission is not so much towards asking for better materials or better casting/forging/welding/coating tech etc, but more towards prevention of invalidating the OEM warranty for the rest of the TF, when such replacements are being made by us. Sufficient indigenous TF D&D capability already exists with us, to achieve something like this.

But, that's precisely why it has put by the Russians in the first place - so that our dependency on the OEM remains as it is - notwithstanding all those shameless tall claims about "100%-production-from-raw-materials" etc.

So as far as Russians are concerned, the only TF that can sufficiently interest us is the 5th Gen Izdeliya-30, which of course Russians would naturally be unwilling to part - I mean will Unkil part any of F135 tech with us - nobody does, so Russians are no exceptions.

A tubelight moment: Now that true-blue-5th-Gen Izdeliya-30/AL-51 is a no-go for us, how about funding Russia, in the so-called joint-D&D (cum-full-IP-sharing - yeah right!!) mode, like that is being touted with Safran/Rolls-Royce, for completing the D&D for a variant (lower dimensional footprint) of the "original" variable-bypass AL-41F (now abandoned) program.

==================================================================================

*Note - Original AL-41F was a monster, being designed to provide Supercruise capability to the (now scrapped) project 1.44.

Re: Kaveri & Aero-Engine: News & Discussion

maitya ji,

we need to become a bit more proactive in this regard, instead of expectantly waiting open mouthed under some random mango tree and hoping against hope that a ripe, juicy, sweet and succulent mango (complete TOT for the latest military jet engine) will miraculously fall into the aforementioned open mouth

the amrikis have got us in a tight lock, trumpwa has stirred the pot in europe and the colonialists there have become not only fearful but also ultra protective of their own behinds and as a result, they rapidly closing nationalist ranks because the memories of WWI and II are still fresh in their NATO influenced minds. The don't trust each other and historically speaking, they never have trusted one another for some centuries now. Now they have become angry and resentful and feel let down by the amrikis whom they all love to look down upon as uncultured and gauche

complacency has been replaced by an element of panic driven urgency because they have been riding the amriki fed and also led NATO coattails for far too long. So any sort of TOT is off the table and there was a frenchman (some CEO) who spoke on this issue very recently and he was angry that they are revealing their technical secrets to the Indians and they should not be doing that

The idea of the nuclear shield is fast fraying and the defense related funds so freely (and foolishly) flowing in from the amriki smorgasbord is bound to end sooner rather than later. A lot of NATO countries are sitting pretty with amriki weapon systems, aircraft and what have you. They now know that free ride this will end

We need to move quickly and also practically. Everyone now knows that this issue cannot be handled with local talent and tech resources, no matter how much money one throws at the problem

The only option is for them to close ranks and gouge India on the weapons market.

In the end we may just have only one option left and that may be the russian one.

Let's hope that things don't come to such a pass

we need to become a bit more proactive in this regard, instead of expectantly waiting open mouthed under some random mango tree and hoping against hope that a ripe, juicy, sweet and succulent mango (complete TOT for the latest military jet engine) will miraculously fall into the aforementioned open mouth

the amrikis have got us in a tight lock, trumpwa has stirred the pot in europe and the colonialists there have become not only fearful but also ultra protective of their own behinds and as a result, they rapidly closing nationalist ranks because the memories of WWI and II are still fresh in their NATO influenced minds. The don't trust each other and historically speaking, they never have trusted one another for some centuries now. Now they have become angry and resentful and feel let down by the amrikis whom they all love to look down upon as uncultured and gauche

complacency has been replaced by an element of panic driven urgency because they have been riding the amriki fed and also led NATO coattails for far too long. So any sort of TOT is off the table and there was a frenchman (some CEO) who spoke on this issue very recently and he was angry that they are revealing their technical secrets to the Indians and they should not be doing that

The idea of the nuclear shield is fast fraying and the defense related funds so freely (and foolishly) flowing in from the amriki smorgasbord is bound to end sooner rather than later. A lot of NATO countries are sitting pretty with amriki weapon systems, aircraft and what have you. They now know that free ride this will end

We need to move quickly and also practically. Everyone now knows that this issue cannot be handled with local talent and tech resources, no matter how much money one throws at the problem

The only option is for them to close ranks and gouge India on the weapons market.

In the end we may just have only one option left and that may be the russian one.

Let's hope that things don't come to such a pass

Re: Kaveri & Aero-Engine: News & Discussion

I don't think Russia is going to give permissions for such things. But, but ..maitya wrote: ↑13 Mar 2025 16:22

We are rather better off, by getting a blanket permission to "improve" AL-31FP, indigenously, part-by-part (especially the Core) - which can result in an, say, AL-31FP-MKI.

This permission is not so much towards asking for better materials or better casting/forging/welding/coating tech etc, but more towards prevention of invalidating the OEM warranty for the rest of the TF, when such replacements are being made by us. Sufficient indigenous TF D&D capability already exists with us, to achieve something like this.

If indeed our R&D is capable of such replacement, we should have a stealth program to iteratively change things on AL-31FP and after our own testing, fly them on Su-30 MKI. Maybe the engine electronic controller has to be reversed engineered to get optimal performance. The craft has two engines, just replace 1 engine with the new Indian engine and test fly. This has to be done under the radar, without anyone squealing on the program. BTW the chinese perhaps did just that to reverse engineer Soviet/Rus maal.

One of the outcome of such reverse engineering is to create an Indian version perhaps not quite the same as the orginal but suitable for engines like Kaveri.

Re: Kaveri & Aero-Engine: News & Discussion

bala wrote: ↑13 Mar 2025 20:14I don't think Russia is going to give permissions for such things. But, but ..maitya wrote: ↑13 Mar 2025 16:22

We are rather better off, by getting a blanket permission to "improve" AL-31FP, indigenously, part-by-part (especially the Core) - which can result in an, say, AL-31FP-MKI.

This permission is not so much towards asking for better materials or better casting/forging/welding/coating tech etc, but more towards prevention of invalidating the OEM warranty for the rest of the TF, when such replacements are being made by us. Sufficient indigenous TF D&D capability already exists with us, to achieve something like this.

If indeed our R&D is capable of such replacement, we should have a stealth program to iteratively change things on AL-31FP and after our own testing, fly them on Su-30 MKI. Maybe the engine electronic controller has to be reversed engineered to get optimal performance. The craft has two engines, just replace 1 engine with the new Indian engine and test fly. This has to be done under the radar, without anyone squealing on the program. BTW the chinese perhaps did just that to reverse engineer Soviet/Rus maal.

One of the outcome of such reverse engineering is to create an Indian version perhaps not quite the same as the orginal but suitable for engines like Kaveri.

bala saar,

back to square 1 again.

Its not about "getting permission", and it's also not about being "nice", and besides who are we really going to offend, because everyone and his/her uncle knows that we are desperate

the cheen never got "permission" from the very first time they stole and copied the early MiGs to now when they are copying russki and western engines, stealing from wherever they can and whenever they can, and they don't understand the meaning of being "nice"

They bought out in its entirety, the israeli lavi project + engineering data, drawings and all of the related stuff, lock stock, and barrel, from them

playing nice and getting permission has got us zilch, as far as, the engine is concerned but we have done well in nuclear submarine building, warships, nuclear power tech, space and other fields and we have found technology partners who have helped us clear hurdles and refine our designs and dare one point out that they are all mostly russki

just get to work on the engine and use resources from wherever available. Not advocating theft or industrial espionage per se, but do not reject it outright. If the opportunity presents itself, let this not be a constraint

This kaveri record has played long enough and that tune has turned screechy a long time ago.

By all means, keep the kaveri project open but at the same time try and open some other avenues to address the roadblocks that were encountered and use a new team to do this, a team that will not be constrained by permissions or even being nice.

Look at all the powerplants being used in India and see if any tech used there can be of help to us.

We are well within our rights to explore options and if possible reverse engineer from the examples that are already familiar to us. If we can integrate this into the kaveri, nothing like it

there are rumours that are they outsourcing the A/B to a missile making company...... that kind of thinking is not just beyond logic but also idiotic.

The harder India pushes for the engine TOT, the more the goras will close ranks

Re: Kaveri & Aero-Engine: News & Discussion

Chetakji, 400% agree wrt taking all possible help and co-development etc that's available from anywhere - even ToT, howsoever fraudulent that concept maybe, has it's own value wrt acquiring/building TF mass-manufacturing technology capability.chetak wrote: ↑13 Mar 2025 19:35 maitya ji,

we need to become a bit more proactive in this regard, instead of expectantly waiting open mouthed under some random mango tree and hoping against hope that a ripe, juicy, sweet and succulent mango (complete TOT for the latest military jet engine) will miraculously fall into the aforementioned open mouth

the amrikis have got us in a tight lock, trumpwa has stirred the pot in europe and the colonialists there have become not only fearful but also ultra protective of their own behinds and as a result, they rapidly closing nationalist ranks because the memories of WWI and II are still fresh in their NATO influenced minds. The don't trust each other and historically speaking, they never have trusted one another for some centuries now. Now they have become angry and resentful and feel let down by the amrikis whom they all love to look down upon as uncultured and gauche

...

...

The only option is for them to close ranks and gouge India on the weapons market.

In the end we may just have only one option left and that may be the russian one.

Let's hope that things don't come to such a pass

I think I've said these points, for many many times now, but a little some more wouldn't really hurt I guess:

1) TF D&D tech capability <> TF mass-Mfg capability. One doesn't automatically lead to other, similarly just mastering one doesn't automatically make one atmanirbhar wrt TF tech.

2) The bigger issue is wrt TF mass-Mfg capability, as it involves developing TF mfg Industrial Ecosystem, which takes time and more importantly, volume. Piecemeal order is a sure-shot mode of killing this capability, and in some cases, actually reversing it.

3) Now, thanks to the Kaveri program we have developed sufficient capability wrt 4th Gen TF D&D.

But that also doesn't mean we have developed a strong enough 4+ Gen TF technological base (similar, but not upto the same-level, of what Safran and Rolls-Royce possess), to be able to graduate to 5th Gen TF D&D independently.

In fact, we should have developed that tech base by now, had Kaveri program was not unceremoniously dumped 1+ decade back.

The KDE program is that proverbial drip-feed that has ensured we don't lose that hard-earned 4th Gen TF D&D capability altogether - but, to expect that to also develop 4+ Gen TF Tech base, so that 5th Gen TF D&D can be taken up with some confidence, is a bit too much.

4) But since Kaveri was never mass-produced, 4th Gen TF mass-Mfg capability was never acquired.

However, we are somewhat of an unique country, as via Lic Mfg of AL-31FP, RD-33MK, Shakti, earlier Adour (3rd Gen) etc, we do have a decent TF mass-Mfg capability as well (may be concentrated with the PSUs, but still it is there).

On the other hand, our Private enterprises (and quite a few MSMEs) have broken into TF mfg ecosystem via being part of global supply-chains of various global OEMs civilian (and maybe some military) TF programs. To be fair they have had some capability historically as well, via the Industrial Turbine manufacturing capabilities for quite some time.

That is the reason why we can suddenly order to a Godrej to manufacture KDE prototypes, and there are other industries (PTC etc) who can confidently manufacture the Turbine components for various GTRE programs etc.

The other day, in one of the interviews, saw Baba Kalyani almost dismissing any challenge wrt manufacturing the cold sections of any TF - whilst admitting, there's steep challenge wrt mastering mass-mfg capability of the hot-section components.

Similarly our small TF (and Turbojet) programs are going great guns , with these very same MSMEs.

5) Any Lic Mfg with decent ToAsT type arrangement, only adds to this (pt 4) capability - provided volumes are there.

That is why I've always advocated F414 ToAsT deal, and in fact have asked for a similar (but even more deeper) Lic Mfg deal for the F404s as well.

It doesn't matter if these deals goes to HAL Engine Div etc, as even then, all major subsystems will get outsourced to these MSMEs anyway.

Now if we are to go ahead and enter into a another Lic Meg deal for, say, the AL-41F1, it's net +ve for the indigenous 4th Gen TF mass-Mfg capability. Ditto if any M88-2 Lic Mfg deals turns up via a large MRFA deal etc.

6) But there shouldn't be any expectations that pt 5 above will somehow magically bring-in first the 4+ Gen TF D&D, and later 5th Gen TF D&D, capabilities. They simply won't.

The only way to bridge that gap, is to actually getting into first D&D of a F414-class TF and then D&D of 5th Gen TF, fully - but since, we being champions of procrastination (compounded with a disdainful attitude towards indigenous R&D), there's simply no such luxuries (wrt timelines) left.

So, the only way is to get involved into both of them in parallel aka

a) Develop (and certify) a 90KN class Kaveri-II (or whatever it's called nowadays)

b) D&D for a 5th Gen TF for AMCA

7) Now for 6(b), since we haven't reached 4+ Gen TF D&D ability yet, this becomes too risky for a national strategic program to be dependent upon.

So, to mitigate such an risk (wrt time-periods involved) a D&D partnership with an global-OEM is required - such an OEM who

a) either already has a 4+ gen TF in mass production (Safran via its M88-2, or Rolls-Royce via EJ200)

b) or already has a 5th Gen TF in mass production (PW via F119 and F135), GE via its 5-minus Gen EPE, Saturn via 5th Gen Izdeliya-30).

8 ) Trouble with 7(b), there's no incentive for these OEMs to be sharing (aka just handing over) the already developed 5th Gen technologies involve, of their frontline products - which essentially rules out PW.

With GE there's still some chance to be able to codevelop a 5th Gen TF, by graduating the EPE tech to a true-blue 5th Gen TF - but then again, having designed YF120 earlier (which lost to PWs YF119), not sure if there's anything really left for GE to redesign or redevelop yet another 5th gen TF program.

With Izdeliya-30/AL-51, there can be some slim-hope if tied to a sufficiently large Su-57 Lic-Mfg deal.

Remember we walked out of the FGFA program, on this very aspect i.e. unavailability of true-blue 5th Gen TF and any talk of its lic mfg that was actively rebuffed, to put it mildly. Of course, there were very many other aspects, which led to that decision, but this is one of the major factors.

9) So, coming back to the topic, when it comes to co-D&D (and so-called IP-sharing

But then again, since there's less than 0% chance of any meaningful D&D IP (lic-mfg yes, similar to maybe the F414 ToAsT program) sharing, irrespective to what our learned Baboons would want us to believe, there needs to be a fallback option.

10) And, another parallel foreign-OEM lead 5th Gen TF joint-D&D program, though ideal, would be cost-prohibitive.

So it's imperative a fully-indigenous 5th Gen TF program (Ganga, anyone?) is funded and pursued with GTRE et all, in parallel.

And that sanction has to pre-date (atleast by a couple of months) before initiating the foreign-OEM lead 5th Gen TF D&D program, so that messaging is not lost on anyone.

Such a program can have a nominal budget of, say, $2B etc - less than 50% of what we are ready to spend on this foreign-OEM lead 5th Gen TF program - and, the whole budget doesn't need to be sanctioned in one go etc, only say a 25-30% for the initial tranche.

Plus, if any of the OEMs who loses the 5th Gen TF joint-D&D program deal, wants to be a fully-paid-program-consultant, so be it!!

(Note: GE has been the most active consultant for the base Kaveri program, so was Safran and to some extent even RR and Saturn as well)

11) Amongst other +ves, of such an arrangement, this will be a very good dis-incentive for the foreign-OEM wrt any hanky-panky over IP/D&D-Tech sharing, that by the way was developed by our funds.

After all, which OEM would want to risk the mouth-watering prospective of hefty-per-platform Lic-mfg-fees in almost-perpetuity (and that too at 0 incremental-cost).

But without such a fallback option, that risk for the foreign-OEM vanishes - so they can then dictate terms wrt which D&D-tech to share and upto what level. And as always, we remain at their mercy - a la F404 for the current Mk1A program.

But but, all of the above means absolute zilch, in absence of any institutional support or seriousness towards such a plan - months and years pass by but even the peanut-budgets for a HATF and FTB doesn't get sanctioned, ditto wrt Kaveri-II program sanction etc etc.

So you are absolutely right when you say that

... expectantly waiting open mouthed under some random mango tree and hoping against hope that a ripe, juicy, sweet and succulent mango (complete TOT for the latest military jet engine) will miraculously fall into the aforementioned open mouth ...

Oh well!!

Re: Kaveri & Aero-Engine: News & Discussion

Maitya

Given that both rr&Safran are ahead of us in tech capability, what 'co-development' will actually happen and how much will we absorb from them if they develop the core and we do the lp and ab sections? Foreign oems developed new alloy compositions for new engines and engine related improvement programs. We have no such dreams.

Given that both rr&Safran are ahead of us in tech capability, what 'co-development' will actually happen and how much will we absorb from them if they develop the core and we do the lp and ab sections? Foreign oems developed new alloy compositions for new engines and engine related improvement programs. We have no such dreams.

Re: Kaveri & Aero-Engine: News & Discussion

maitya ji,maitya wrote: ↑14 Mar 2025 13:36Chetakji, 400% agree wrt taking all possible help and co-development etc that's available from anywhere - even ToT, howsoever fraudulent that concept maybe, has it's own value wrt acquiring/building TF mass-manufacturing technology capability.chetak wrote: ↑13 Mar 2025 19:35 maitya ji,

we need to become a bit more proactive in this regard, instead of expectantly waiting open mouthed under some random mango tree and hoping against hope that a ripe, juicy, sweet and succulent mango (complete TOT for the latest military jet engine) will miraculously fall into the aforementioned open mouth

the amrikis have got us in a tight lock, trumpwa has stirred the pot in europe and the colonialists there have become not only fearful but also ultra protective of their own behinds and as a result, they rapidly closing nationalist ranks because the memories of WWI and II are still fresh in their NATO influenced minds. The don't trust each other and historically speaking, they never have trusted one another for some centuries now. Now they have become angry and resentful and feel let down by the amrikis whom they all love to look down upon as uncultured and gauche

...

...

The only option is for them to close ranks and gouge India on the weapons market.

In the end we may just have only one option left and that may be the russian one.

Let's hope that things don't come to such a pass

I think I've said these points, for many many times now, but a little some more wouldn't really hurt I guess:

1) TF D&D tech capability <> TF mass-Mfg capability. One doesn't automatically lead to other, similarly just mastering one doesn't automatically make one atmanirbhar wrt TF tech.

2) The bigger issue is wrt TF mass-Mfg capability, as it involves developing TF mfg Industrial Ecosystem, which takes time and more importantly, volume. Piecemeal order is a sure-shot mode of killing this capability, and in some cases, actually reversing it.

3) Now, thanks to the Kaveri program we have developed sufficient capability wrt 4th Gen TF D&D.

But that also doesn't mean we have developed a strong enough 4+ Gen TF technological base (similar, but not upto the same-level, of what Safran and Rolls-Royce possess), to be able to graduate to 5th Gen TF D&D independently.

In fact, we should have developed that tech base by now, had Kaveri program was not unceremoniously dumped 1+ decade back.

The KDE program is that proverbial drip-feed that has ensured we don't lose that hard-earned 4th Gen TF D&D capability altogether - but, to expect that to also develop 4+ Gen TF Tech base, so that 5th Gen TF D&D can be taken up with some confidence, is a bit too much.

4) But since Kaveri was never mass-produced, 4th Gen TF mass-Mfg capability was never acquired.

However, we are somewhat of an unique country, as via Lic Mfg of AL-31FP, RD-33MK, Shakti, earlier Adour (3rd Gen) etc, we do have a decent TF mass-Mfg capability as well (may be concentrated with the PSUs, but still it is there).

On the other hand, our Private enterprises (and quite a few MSMEs) have broken into TF mfg ecosystem via being part of global supply-chains of various global OEMs civilian (and maybe some military) TF programs. To be fair they have had some capability historically as well, via the Industrial Turbine manufacturing capabilities for quite some time.

That is the reason why we can suddenly order to a Godrej to manufacture KDE prototypes, and there are other industries (PTC etc) who can confidently manufacture the Turbine components for various GTRE programs etc.

The other day, in one of the interviews, saw Baba Kalyani almost dismissing any challenge wrt manufacturing the cold sections of any TF - whilst admitting, there's steep challenge wrt mastering mass-mfg capability of the hot-section components.

Similarly our small TF (and Turbojet) programs are going great guns , with these very same MSMEs.

5) Any Lic Mfg with decent ToAsT type arrangement, only adds to this (pt 4) capability - provided volumes are there.

That is why I've always advocated F414 ToAsT deal, and in fact have asked for a similar (but even more deeper) Lic Mfg deal for the F404s as well.

It doesn't matter if these deals goes to HAL Engine Div etc, as even then, all major subsystems will get outsourced to these MSMEs anyway.

Now if we are to go ahead and enter into a another Lic Meg deal for, say, the AL-41F1, it's net +ve for the indigenous 4th Gen TF mass-Mfg capability. Ditto if any M88-2 Lic Mfg deals turns up via a large MRFA deal etc.

6) But there shouldn't be any expectations that pt 5 above will somehow magically bring-in first the 4+ Gen TF D&D, and later 5th Gen TF D&D, capabilities. They simply won't.

The only way to bridge that gap, is to actually getting into first D&D of a F414-class TF and then D&D of 5th Gen TF, fully - but since, we being champions of procrastination (compounded with a disdainful attitude towards indigenous R&D), there's simply no such luxuries (wrt timelines) left.

So, the only way is to get involved into both of them in parallel aka

a) Develop (and certify) a 90KN class Kaveri-II (or whatever it's called nowadays)

b) D&D for a 5th Gen TF for AMCA

7) Now for 6(b), since we haven't reached 4+ Gen TF D&D ability yet, this becomes too risky for a national strategic program to be dependent upon.

So, to mitigate such an risk (wrt time-periods involved) a D&D partnership with an global-OEM is required - such an OEM who

a) either already has a 4+ gen TF in mass production (Safran via its M88-2, or Rolls-Royce via EJ200)

b) or already has a 5th Gen TF in mass production (PW via F119 and F135), GE via its 5-minus Gen EPE, Saturn via 5th Gen Izdeliya-30).

8 ) Trouble with 7(b), there's no incentive for these OEMs to be sharing (aka just handing over) the already developed 5th Gen technologies involve, of their frontline products - which essentially rules out PW.

With GE there's still some chance to be able to codevelop a 5th Gen TF, by graduating the EPE tech to a true-blue 5th Gen TF - but then again, having designed YF120 earlier (which lost to PWs YF119), not sure if there's anything really left for GE to redesign or redevelop yet another 5th gen TF program.

With Izdeliya-30/AL-51, there can be some slim-hope if tied to a sufficiently large Su-57 Lic-Mfg deal.

Remember we walked out of the FGFA program, on this very aspect i.e. unavailability of true-blue 5th Gen TF and any talk of its lic mfg that was actively rebuffed, to put it mildly. Of course, there were very many other aspects, which led to that decision, but this is one of the major factors.

9) So, coming back to the topic, when it comes to co-D&D (and so-called IP-sharing) of a 5th Gen TF for the AMCA program, we are basically left with Safran and RR, to partner and fund this 5th Gen TF D&D program with.

But then again, since there's less than 0% chance of any meaningful D&D IP (lic-mfg yes, similar to maybe the F414 ToAsT program) sharing, irrespective to what our learned Baboons would want us to believe, there needs to be a fallback option.

10) And, another parallel foreign-OEM lead 5th Gen TF joint-D&D program, though ideal, would be cost-prohibitive.

So it's imperative a fully-indigenous 5th Gen TF program (Ganga, anyone?) is funded and pursued with GTRE et all, in parallel.

And that sanction has to pre-date (atleast by a couple of months) before initiating the foreign-OEM lead 5th Gen TF D&D program, so that messaging is not lost on anyone.

Such a program can have a nominal budget of, say, $2B etc - less than 50% of what we are ready to spend on this foreign-OEM lead 5th Gen TF program - and, the whole budget doesn't need to be sanctioned in one go etc, only say a 25-30% for the initial tranche.

Plus, if any of the OEMs who loses the 5th Gen TF joint-D&D program deal, wants to be a fully-paid-program-consultant, so be it!!

(Note: GE has been the most active consultant for the base Kaveri program, so was Safran and to some extent even RR and Saturn as well)

11) Amongst other +ves, of such an arrangement, this will be a very good dis-incentive for the foreign-OEM wrt any hanky-panky over IP/D&D-Tech sharing, that by the way was developed by our funds.

After all, which OEM would want to risk the mouth-watering prospective of hefty-per-platform Lic-mfg-fees in almost-perpetuity (and that too at 0 incremental-cost).

But without such a fallback option, that risk for the foreign-OEM vanishes - so they can then dictate terms wrt which D&D-tech to share and upto what level. And as always, we remain at their mercy - a la F404 for the current Mk1A program.

But but, all of the above means absolute zilch, in absence of any institutional support or seriousness towards such a plan - months and years pass by but even the peanut-budgets for a HATF and FTB doesn't get sanctioned, ditto wrt Kaveri-II program sanction etc etc.

So you are absolutely right when you say that

... expectantly waiting open mouthed under some random mango tree and hoping against hope that a ripe, juicy, sweet and succulent mango (complete TOT for the latest military jet engine) will miraculously fall into the aforementioned open mouth ...

Oh well!!

In your opinion, what are the major differences between the Russian engine technology & American / French / English engine technology? What makes the American / French engines to last longer compared to the Russian engines? What could have GTRE / HAL learned from license manufacturing engines like AL-31 / adour? Did / Can any of these learnings help in weight reduction of Kaveri?

Re: Kaveri & Aero-Engine: News & Discussion

Please *DO NOT* requote such a long post. Your Post Has Been Edited.konaseema wrote: ↑15 Mar 2025 02:42maitya ji,

In your opinion, what are the major differences between the Russian engine technology & American / French / English engine technology? What makes the American / French engines to last longer compared to the Russian engines? What could have GTRE / HAL learned from license manufacturing engines like AL-31 / adour? Did / Can any of these learnings help in weight reduction of Kaveri?

Many users visit BRF on mobile phone. Please be mindful of other readers. Thank You.

Re: Kaveri & Aero-Engine: News & Discussion

I'll write a detailed post later (provided I get some b/w from somewherePrasad wrote: ↑15 Mar 2025 00:04 Maitya

Given that both rr&Safran are ahead of us in tech capability, what 'co-development' will actually happen and how much will we absorb from them if they develop the core and we do the lp and ab sections? Foreign oems developed new alloy compositions for new engines and engine related improvement programs. We have no such dreams.

However, since you bring-in the "new alloy composition" aspect, let me say the following:

A 5th Gen TF would surely need a 1850+ deg K TeT capability (so >1580-90deg C), whilst their (Safran/RR et all) current 4+ Gen products boasts 1530-1550 deg C TeT capable SC casted HPT blades/vanes.

Trouble is, I normally try my best to not get into concrete figures like this, as inevitably people deduce this 40-50deg TeT "gap" as trivial, which then essentially results into "almost there" kind of false-narrative building.

This gap (of 40deg C), in SC casted Ni-Superalloy domain, is atleast a generational gap, if not more - not only wrt raw-metal temp handling capabilities but also wrt the TBC etc technologies that are already involved.

Just as an example, one can't just declare victory stating that since the have now developed, say a 1140deg C temp-handling capable next gen (say 4-5th Gen) SC Superalloy, based on their current 1100deg C temp-handling Superalloy (say 3rd Gen) tech etc.

It doesn't work that way - not only such next Gen SC superalloys are required, but also a host of other next-Gen technologies would be required to actually fully-utilize such capability.

Just as an example, in such a scenario, you may end-up requiring a bilayer TBC tech as well, to leverage this next-Gen SC technology, to be able to deliver the intended 40deg C TeT increment finally.

But where does that leave us - the already TF tech-pichchde folks, languishing at 1050deg C DS casted Superalloy technologies. There must be no hope right?

Wrong, there many ways of skinning the cat, afterall:

Now, continuing with the previous example, to able to deliver this addn 40-50deg C TeT capability, you don't necessarily have to develop an addn 40-50deg C metal-temp capable next Gen SC.

As an alternative path, you can always develop a brand new convectional-cooling (film-cooling) architecture and meet this addn 40deg C addn TeT capability. That way, as a bonus, you don't need to go for a bilayer TBC tech etc - your existing, say 8-YSZ, TBC technology will suffice.

The catch here is of-course, like everything else, there're tech limits upto how much you can leap-frog like this - i.e. now, designing a film-cooling tech/architecture that delivers addn 90-100deg C cooling, so that your 1050deg C metal-temp capable superalloys would suffice, may not be possible in the first place.

Remember the biggest advantage of SC casted blades, vis-a-vis DS casted blades, despite the popular myth wrt raw-temp handling capabilities, is wrt their thin-section strength capabilities etc.

(Pls refer to the Kaveri Gyan thread for details)

So, you will still be required to first graduate to, as per the above example, a 1100-1110deg C capable SC-Superalloy technology. Then only, you will be able to leverage, such "alternate paths" (mentioned above), to achieve those 5th Gen TF (1590+ deg C) TeT levels.

Further alternative approach can be, maybe an combination both is possible - aka 1080deg C capable SC-Superalloy (e.g. in a 2nd Gen like CMSX4) alongside slightly superior film-cooling tech/architecture of say 60-70 deg C addn cooling level.

etc etc.

Also, it's one thing to design and then lab-level-demo of a 4-5th Gen SC Superalloy based HPT blades/vanes - it's quite another to implement that next-gen technology at a commercially-viable mass-manufacturing level (most such advancements actually fail just at these aspects).

(Again pls refer to my previous posts, both here and in the gyan thread, wrt this aspect - hint, just as an example the LAB effect)

Anyway, there are many such nuances involved, which will require a detailed post to bring those out.

============================================================================================================

PS: The figures used above, quite deliberately, should provide enough hints, wrt "mapping/co-relating" to 4 Gen TF (like Kaveri) Tech, 4+ Gen TF (like M88-2/EJ200) Tech and an aspirational 5th Gen TF Tech.

Re: Kaveri & Aero-Engine: News & Discussion

https://shirobarks.blogspot.com/2025/03 ... -saga.html

Putting the whole article, lots of data to chew on. mods if copyright issue,please feel free to delete.

The Kaveri Saga

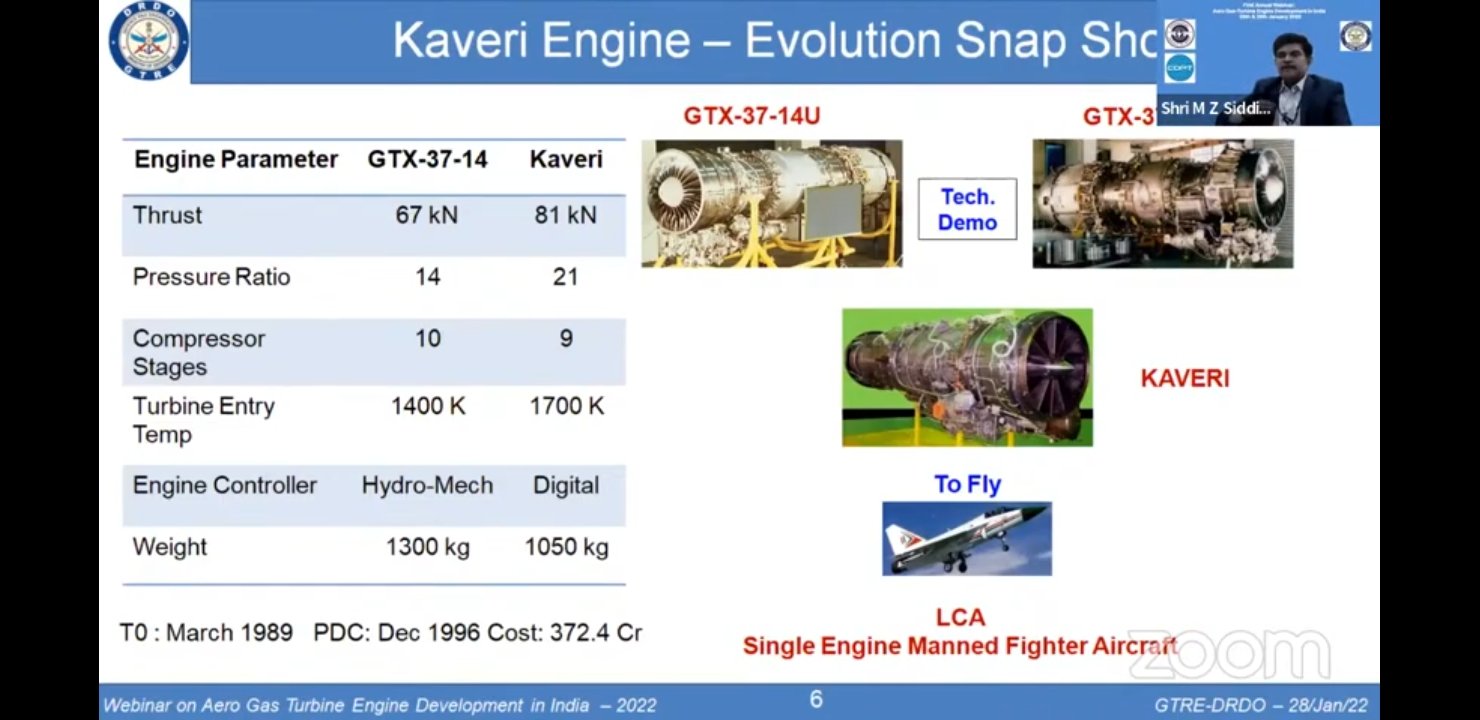

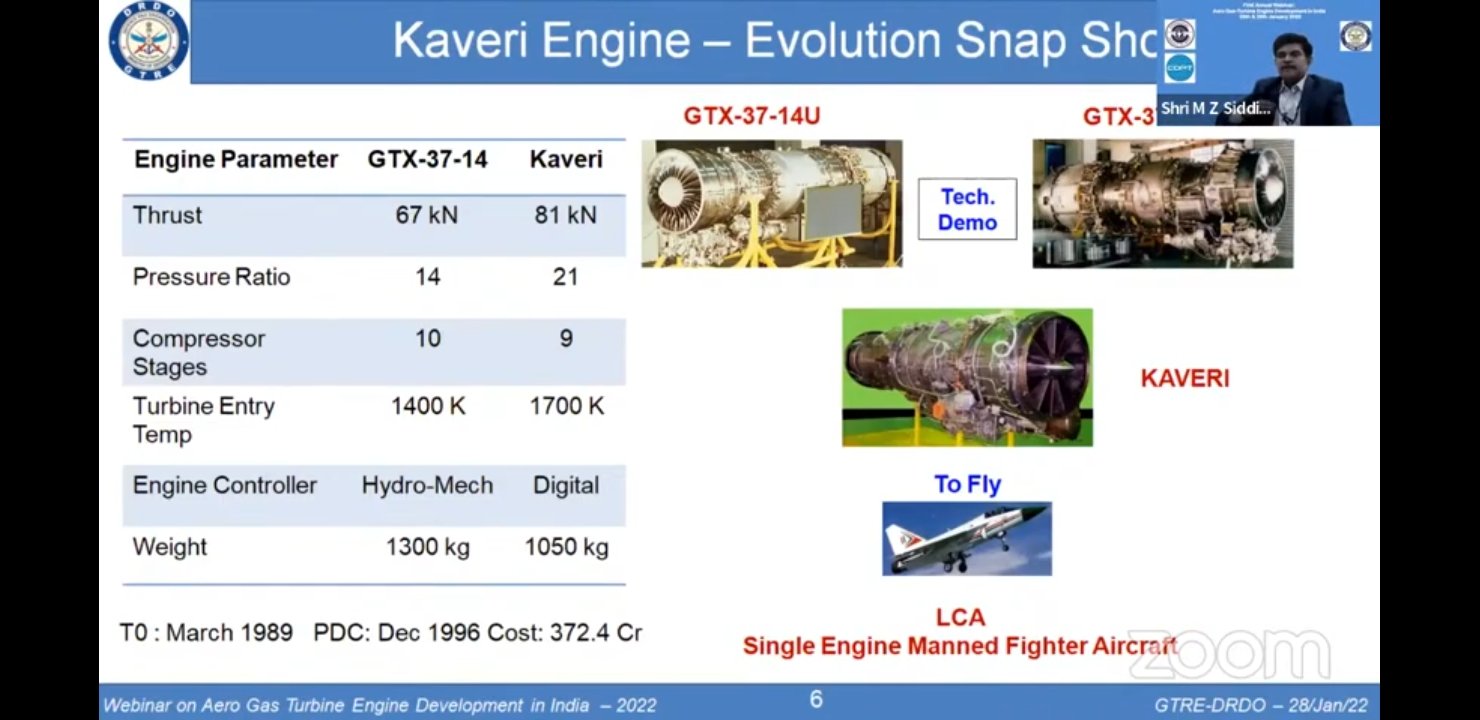

Kaveri, an afterburning turbofan engine, was sanctioned on 30th March 1989 for ₹382.21 crore and was made to power the then-under development LCA. The venture was placed under GTRE, who already had quite an experience making engines. GTX37-14U was an augmented turbojet engine in 1977 and demonstrated in 1981, or a centrifugal type 10 kN thrust engine (i.e., F107-WR-105), which they made around 1959.

Another low-bypass engine was made called GTX37-14UB with GTX 37-14U as its core, which was an 89 kN Class engine; it was proposed for LCA before Kaveri but was overruled due to its large frontal section. The GTX 37-14U was a flat-rated twin-spool turbojet having a throttle ratio of 1.13 and a bypass ratio of 0.2:1.

Again, GTX 37-14U was also suffering from its own fair share of problems. Let's talk about Kaveri or GTX-35VS: It's an afterburning, twin-spool, low-bypass turbofan engine. It borrows its core, called Kabini, from it.

In simple terms, twin spool means. A two-spool engine features two concentric shafts that rotate at different speeds: one links the high-pressure turbine stages to the high-pressure compressor, while the other connects the low-pressure turbine stages to the low-pressure compressor and fan.

A Twin-Spool Engine Diagram

A low bypass means an engine where the amount of air bypassing the engine core (Bypass Flow) is relatively small compared to the amount of air that passes through the core (Core Flow).

The design of Kaveri includes:

Compressor: 3 Low-Pressure Compressor Stages | 6 High-Pressure Compressor Stages with variable inlet stator vanes on the first 2 stages.

Turbine: 1-stage LPT and 1-stage High-Pressure Turbine and Low-Pressure turbine using DS both blades at the start.

Convergent-divergent short annular system with step diffuser combustion: A nozzle with converging and diverging sections, a compact ring-shaped combustion chamber, and a diffuser with steps to manage airflow and pressure

Kaveri engine cross section model

At the start, the Kaveri had 5 stages of high-pressure compressor, which were increased to 6 based on suggestions of a retired chief designer from GE, Peter Chipporus.

One day in March 1988, Arunachalam told me that I should come to DRDO Head Quarters to take up the position of Chief Controller R&D. I resisted initially as this was a pure desk job, but I yielded. At one stage, I was assisting more than half of the technical laboratories. I was also in charge of the human resources development. But, I got bored doing this desk job as CCR&D and requested Arunachalam to send me back to a laboratory. He gave me a couple of options and 1 chose to be posted as Director of the Gas Turbine Research Establishment at Bangalore with effect from 1 January 1990. I was not a gas turbine specialist, but materials problems of the engine contributed to more than 50% in the engine development. Kaveri design incorporated the use of a variety of nickel base superalloys and titanium alloys. Thus, I was sure of making my contributions in the development of the engine.

Unlike NCML, GTRE, a major systems laboratory had more than 1500 employees and a strong employees union. It had built the after burner for the Orpheus 703 engine, but that was not accepted because it was over-weight. It had built two technology demonstrator engines designated GTX 37-14U and GTX 37-14UB, the former being a straight jet, while the later a bypass version. This had given confidence to GTRE to bid for building the flat rated gas turbine engine (Kaveri) for the Light Combat Aircraft. The design of the Kaveri engine was based on a mixture of eastern and western philosophies. Obviously, several problems did surface. Prior to my joining GTRE, reputed jet engine manufacturers like Rolls Royce, Snecma and General Electric had shown interest in participating in our engine development programme, but that was turned down due to some reason or other. After my joining GTRE, Mr. Peter Chipporus, a retired chief designer from GE came for discussions and based on his suggestion, the number of stages in the high pressure compressor was increased from 5 to 6. Also, it was brought out that the engine design dimensions specified correspond to the operating conditions and one needs to take into account thermal as well as centrifugal expansion to arrive at the dimensions for manufacturing. Another problem pertained to dimensional distortion due to residual stresses arising out of welding/machining. I assisted in developing a step wise annealing schedule to reduce the distortion to the minimum.

Most of the superalloys required for the manufacture of various discs and blades were initially imported, but later MIDHANI developed all the alloys which were certified by CEMILAC, the agency for certification of materials for air-worthiness. From the designers' point of view, it was necessary to generate adequate data of the materials in use and hence a separate facility, Aeronautical Materials Testing Laboratory, was established near Midhani.

While most of the engine testing facilities was available, we had to go overseas to get some specialized testing done. Russia offered these tests at a lower cost, but procedural delays were considerable. GTRE had 5 engine test beds and it used to test the prototype only once a day. I suggested that it has to be done more number of times a day, as otherwise we may not be able to meet the project schedule. And it was done. My moment of happiness was when the first prototype of Kaveri was test run in 1994.

Kaveri was an overambitious project from the start with a very low budget compared to its equivalents, which is why, with a total of 2,839 crore spent, it was delinked from Tejas in 2008. Everyone was more or less fine with this decision. IAF said they will only order LCA in substantial numbers only if it meets their ASRs. It was supposed to use even lower compressor stages than RD33 and achieve overambition targets. In 2008 the Kaveri was able to achieve ~73 kN of thrust with AB and 49 kN of dry thrust. The Kaveri was able to achieve its dry thrust more or less; the problems start with the afterburner, where it has a shortfall. Below are the design specs of Kaveri:

Specification Value Specification Value

Power Plant For TEJAS (LCA) Engine Type Twin Spool, Low Bypass

Air Mass Flow 78 kg/sec Bypass Ratio 0.16 - 0.18

Overall Pressure Ratio 21.5 TET (Turbine Entry Temp.) 1487 - 1700 K

Max Thrust (Dry) 52 kN Max Thrust (Afterburner) 81 kN

SFC (Dry) 0.78 kg/hr/kg Max SFC with Afterburner 2.03 kg/hr/kg

Thrust-to-Weight Ratio 7.8

Kaveri also has a shortfall of around 12%, and it has produced 70-75 kN throughout its development. There are a total of 10 versions of Kaveri: from K1 to K9, K9+, or K9*. Kaveri was started with an ambitious weight target of 1000 kg. Later revised to 1100 kg for LCA and again revised to 1050 kg. The first Kaveri engine (K1) weighed 1423.78 kg. GTRE undertook weight reduction exercise starting in 1993, and the weight of K9 was 1235 kg and finally the K9+, which is 1180 kg. To further reduce the weight, the use of blisks (bladed disks), PMC ducts, which weigh 26 kg compared to metallic 32 kg, and powder metallurgy disks, which will require a high-pressure isothermal press that India does not possess as of now, we do have a 2000 MT ton isothermal forge at MIDHANI, which was used to make disks for all five stages of the high-pressure compressor of andour engines, which power the Jaguar aircrafts of the IAF. The aim of Kaveri has achieved a thrust-to-weight ratio of 6.5 against the target of 8.

The thrust and weight shortfalls are just the tip of the iceberg; Kaveri also had a fair share of other problems:

U Certain critical and crucial activities for successful development of Kaveri, viz. development of Compressor, Turbine and Engine Control System, have been lagging behind despite increase in cost by Rs 186.61 crore - CAG Report No. 16 of 2010

GTRE has been unable to freeze the design of the turbine blades, the compressor has witnessed mechanical failure in performance and the engine control system is not flight-worthy. - CAG Report No. 16 of 2010

The Kaveri engine which is designed to meet the conditions of operating fighters in the Indian environment is perhaps technologically more challenging than the airframe.

The Core Engine demonstration, which was planned for 1990, happened in 1995; Full Engine was demonstrated in 1995 instead of the planned 1992. The historical circumstances and geopolitics didn't help the program either. The LCA was to use Kaveri in the production variant while using Electric F404-GE-F2J3. In 1995, the US approved the sale of the 404 engine to India, and eleven of them were purchased to be fitted in early demonstrators of the LCA.

In 1998, after the Pokhran Tests, the US sanctioned India, all support was withdrawn, and the LCA's last hope was the Kaveri engine. In 2001, LSP-1 made its first flight at Mach 2.1 powered with an F404-F2J3. The US sanctions were lifted, and Tejas went into production with F404-IN20 engines.

The main issues with Kaveri engines were blade flutter, screeching noise, and afterburner oscillations. There were also problems with the low-pressure compressor, which is why the entire frontal section was redesigned for KDE. The problem with the fan was that of efficiency surge margin and flutter; for HPC, it was blade high-cycle fatigue failure and shortfall of performance compared to what was expected. For combustors it was pressure loss, pattern factor, and structural integrity; for afterburners it was screech, thrust boost, and buckling. At the time of writing this article, all the problems are mostly solved. The issue with afterburner instability was with the fuel spray nozzles, and mostly the afterburner was stretched.

There was also an issue of flickering, which was solved back in 2010. Another issue is the very low bypass ratio, which leaves less air for cooling. The in-house blades used by GTRE initially failed; this led GTRE to procure disks, blades, and control systems from Snecma. The major issues with Kaveri as of today are resolved. Safran did an audit on the engine a couple of times; they noticed some problems with the afterburner, and they were resolved.

13 engines are made till 2021, including 9 full prototypes (K1 to K9) and 4 core engines, all upgraded to the K9+ standard.

Two of the six Kaveri engines made in 1998 went for testing in Russia at CIMA, and a series of tests over two years were to examine its ability to withstand low pressure and temperature at high altitudes. Later in 2004, Kaveri failed high altitude testing in Russia. By 2008 Kaveri underwent 1,700 hours of ground testing in India and was sent to Russia twice. In 2011-12, Kaveri was tested in Russia by replacing one of the four engines of the Il-76 at a maximum altitude of 12 km and a forward speed of 0.7 Mach.

After conducting thorough engine ground runs, the scientists successfully completed the taxi trials and the maiden flight test of the Kaveri engine with the IL-76 aircraft on November 3rd, 2011, followed by three additional flight tests. The engine was again successfully tested in 2012 at an altitude of 6000 ft at Mach 0.6 speed for 55 hours in Russia. During this testing, Kaveri was able to achieve 49.2 kN dry thrust against a 51 kN target and 70.4 kN wet thrust against 81 kN.

In 2012, it was confirmed that a version of Kaveri (K9+) with its afterburner removed, called the Kaveri Derivative Engine (KDE), will be used to power the Indian Unmanned Strike Air Vehicle, or AURA, what is now called the Ghatak UCAV.

During this time there was also a proposal to invite a foreign engine house to solve the problems with the Kaveri engine called K10. This was in discussion since 2008 but was never approached. In 2014 France proposed investing 1 billion euros as part of the Dassault Rafale offsets deal and suggested a joint venture with DRDO to swiftly revive the Kaveri engine program and make it airworthy by 2018. Everyone was fine with it; it required them to do nothing. Later, France offered the M88 core to be used, and this venture fell apart.

Kaveri was using DS blades in the LPT and HPT section, but the KDE is using CMSX4 for HPT blades, as revealed in an interview by Dr. S.V. Ramana Murthy (GTRE Director), who also recommended India to set up its own strategic materials reserve to store or bank critical materials that India will require for making these engines. He also talked about CMSX4 blades being made in India but raw materials still being imported.

We have also developed a TBC coating unit with ARCI, Hyderabad, and DMRL for yttria-stabilized zirconia coating. The project is more or less in research mode and has not been used for production yet. The SX blades in KDE does use TBC coating, but it is applied by some other machine. ARCI has also developed 150 kW Axial Suspension Plasma Spray, an alternative method for TBC. GTRE is also using EDM machines from Makino for cooling holes.

Talking about single-crystal blades, the HAL makes single-crystal blades for AL31FP engines, which power the Su-30MKI of the IAF, using the Bridgman–Stockbarger technique. The AL31 engine is 53% by cost indigenous and 87% of the components. One can imagine the disks and raw materials are still being imported. A contract was signed with HAL to make 240 AL31FP engines to overhaul Su-30s. The indigenous content will climb to 63% and average 54%.

DMRL has also developed their own single-crystal blades, like DMS4 with intricate cooling channels. The DMS4 is officially a 3rd Gen SX alloy, although there exists an argument that DMS4 is a 4th gen alloy; we will stick to the official definition given in papers published by DMRL. DMS4 is in the same league as CMSX10, Rene N6, and TMS75. DMS4 offers 1140°C TET compared to 1104°C of Rene N6. DMS4 is also patented. It also has a metal temperate capability of 1140°C against 1135°C of CMSX10, 1110°C of TMS 75 and 1150°C of TMS 196 (5th gen alloy) used in XF5(49 kN Japanese engine). Also, one can imagine the TET you can achieve with proper use of DMS4 from its heat treatment. The details about DMS4 show that it lies in the same league as some of the alloys.

Info about DMS4 from:

In the fully heat-treated condition, DMS4 offers more than 80°C metal temperature advantage over the first generation single crystal superalloy CMSX2 and about 8°C advantage over modern third generation alloys such as CMSX10

Fully solutionized between 1315°C - 1360°C over 24 hours with a heat treatment window of 20°C.

Shows superior 1% creep strength and creep rupture life comparable to CMSX10.

Alloy: DMS4M

Solution Heat Treatment:

1340°C for 5 hours

1350°C for 5 hours

1355°C for 10 hours

1360°C for 15 hours, followed by air cooling

First Aging Heat Treatment:

1160°C for 6 hours, followed by air cooling

Second Aging Heat Treatment:

870°C for 20 hours, followed by air cooling

Third Aging Heat Treatment:

760°C for 30 hours, followed by air cooling

There is also DMD4, a directionally solidified alloy derived from DMS4. Developed as a columnar grain superalloy for cost-effective turbine airfoil parts. Solutionized between 1300°C and 1330°C over 30 hours.

Now the question is why aren’t we using DMS4 if we have it? I think it was because the goal was never the performance; Kaveri already had a lot of trouble back in 2010, and they were dealing with it, and on top of it, introducing an untested, new material in the engine would have complicated their already very complicated problems. Since they have chosen tried and tested CMSX4, a second-generation alloy to be used in HPT of KDE. The Kabini was using Supercast 247A; maybe that's been replaced with the superior DMD4 alloy. Kaveri was also using Superni 718A for HPC. MIDHANI has also developed the Superni-115 LPT blade blank, although it can't be confirmed if Kaveri is using it or not.

DMRL has also made low-pressure turbine blisks for STFE engines. DMRL has also worked on serpentine air cooling for SX blades.

The first KDE was delivered to GTRE in late 2024, soon followed by a second prototype, with both undergoing high-altitude testing in Russia. Where they have more or less achieved their goals. According to a report by ET, on Dec 24, 2024, after completing its high-altitude testing, the engine is ready for real-world evaluation on a flying test bed.

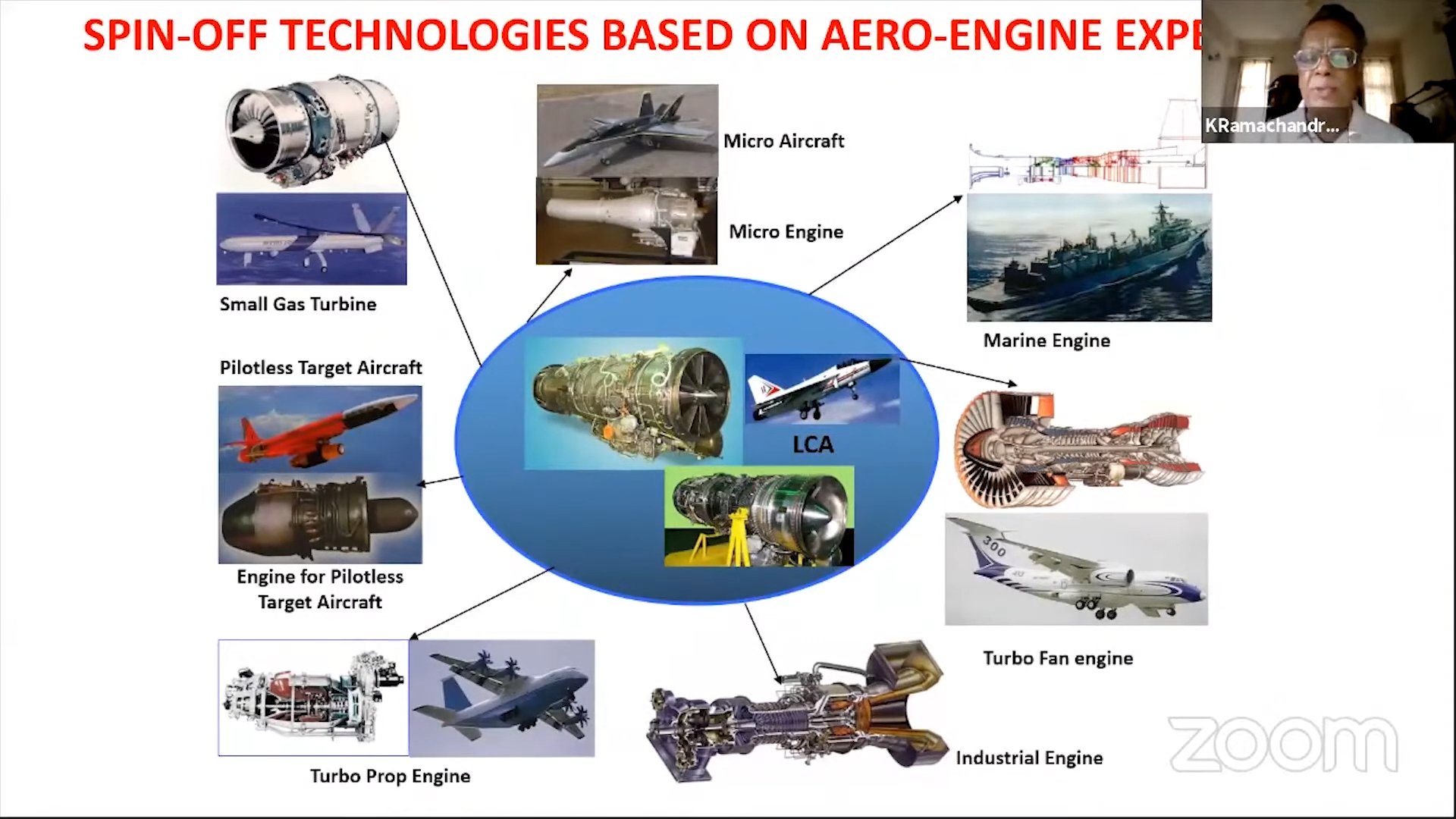

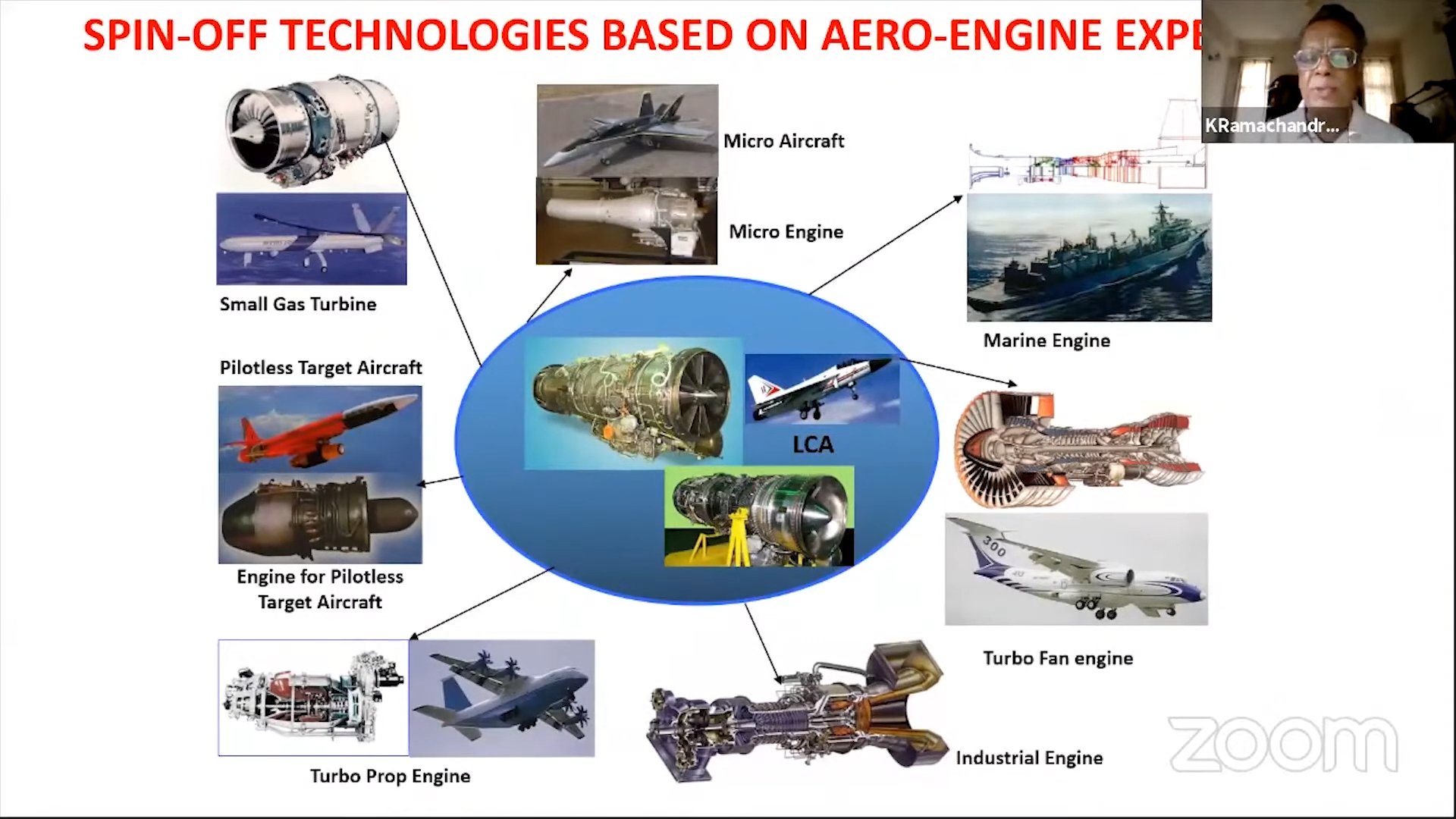

There is another simultaneous project going on where a redesigned afterburner is being made by BrahMos Aerospace, who won the tender in 2020 from GTRE. The AB will then be integrated with KDE and will probably be used on a dual-engine aircraft or LSP Tejas for certification and demonstration purposes.

Today, India has all the building blocks to make its own 4th-gen engine with many PSUs and private players being the first-tier suppliers for global OEMs. A lot of work is being done on composite materials to sustain temperatures as high as 2000°C. Other than GTRE, there is also the Aero Engine Research and Design Center (AERDC) of HAL's engine R&D wing, which has developed the HTFE-25 and HTSE-1200 engines, although the technology is a generation older than what is used in Kaveri. Then there is also MIDHANI, which has developed a wide range of materials since the program began, including materials like Inconel 718.

The majority of problems can be solved, and India can have its own engine with adequate manufacturing and testing infrastructure. But to be optimistic, HAL is setting up a national facility with a 50,000-ton die forge press and a 20,000-ton isothermal press. For many uses, the facility will also make titanium bulkheads for AMCA. The 20,000-ton iso press will be used to make powder metallurgy disks. Then India will need to use blisk for weight reduction of the engine. and use of composite materials in the AB.

Then there is the joint venture deal with foreign OEMs to make a 110 kN engine, which will replace GE F414-IN6 in the future, the front runners of this deal being Rolls-Royce and Safran. Both are offering everything India lacks more or less, and the deal basically includes GTRE getting know-how and know-why, a flying test bed, and other manufacturing and testing infrastructure required to make this engine. The development of this engine will take 10-15 years and will require funding of $4-6 billion USD.

Putting the whole article, lots of data to chew on. mods if copyright issue,please feel free to delete.

The Kaveri Saga

Kaveri, an afterburning turbofan engine, was sanctioned on 30th March 1989 for ₹382.21 crore and was made to power the then-under development LCA. The venture was placed under GTRE, who already had quite an experience making engines. GTX37-14U was an augmented turbojet engine in 1977 and demonstrated in 1981, or a centrifugal type 10 kN thrust engine (i.e., F107-WR-105), which they made around 1959.

Another low-bypass engine was made called GTX37-14UB with GTX 37-14U as its core, which was an 89 kN Class engine; it was proposed for LCA before Kaveri but was overruled due to its large frontal section. The GTX 37-14U was a flat-rated twin-spool turbojet having a throttle ratio of 1.13 and a bypass ratio of 0.2:1.

Again, GTX 37-14U was also suffering from its own fair share of problems. Let's talk about Kaveri or GTX-35VS: It's an afterburning, twin-spool, low-bypass turbofan engine. It borrows its core, called Kabini, from it.

In simple terms, twin spool means. A two-spool engine features two concentric shafts that rotate at different speeds: one links the high-pressure turbine stages to the high-pressure compressor, while the other connects the low-pressure turbine stages to the low-pressure compressor and fan.

A Twin-Spool Engine Diagram

A low bypass means an engine where the amount of air bypassing the engine core (Bypass Flow) is relatively small compared to the amount of air that passes through the core (Core Flow).

The design of Kaveri includes:

Compressor: 3 Low-Pressure Compressor Stages | 6 High-Pressure Compressor Stages with variable inlet stator vanes on the first 2 stages.

Turbine: 1-stage LPT and 1-stage High-Pressure Turbine and Low-Pressure turbine using DS both blades at the start.

Convergent-divergent short annular system with step diffuser combustion: A nozzle with converging and diverging sections, a compact ring-shaped combustion chamber, and a diffuser with steps to manage airflow and pressure

Kaveri engine cross section model

At the start, the Kaveri had 5 stages of high-pressure compressor, which were increased to 6 based on suggestions of a retired chief designer from GE, Peter Chipporus.

One day in March 1988, Arunachalam told me that I should come to DRDO Head Quarters to take up the position of Chief Controller R&D. I resisted initially as this was a pure desk job, but I yielded. At one stage, I was assisting more than half of the technical laboratories. I was also in charge of the human resources development. But, I got bored doing this desk job as CCR&D and requested Arunachalam to send me back to a laboratory. He gave me a couple of options and 1 chose to be posted as Director of the Gas Turbine Research Establishment at Bangalore with effect from 1 January 1990. I was not a gas turbine specialist, but materials problems of the engine contributed to more than 50% in the engine development. Kaveri design incorporated the use of a variety of nickel base superalloys and titanium alloys. Thus, I was sure of making my contributions in the development of the engine.

Unlike NCML, GTRE, a major systems laboratory had more than 1500 employees and a strong employees union. It had built the after burner for the Orpheus 703 engine, but that was not accepted because it was over-weight. It had built two technology demonstrator engines designated GTX 37-14U and GTX 37-14UB, the former being a straight jet, while the later a bypass version. This had given confidence to GTRE to bid for building the flat rated gas turbine engine (Kaveri) for the Light Combat Aircraft. The design of the Kaveri engine was based on a mixture of eastern and western philosophies. Obviously, several problems did surface. Prior to my joining GTRE, reputed jet engine manufacturers like Rolls Royce, Snecma and General Electric had shown interest in participating in our engine development programme, but that was turned down due to some reason or other. After my joining GTRE, Mr. Peter Chipporus, a retired chief designer from GE came for discussions and based on his suggestion, the number of stages in the high pressure compressor was increased from 5 to 6. Also, it was brought out that the engine design dimensions specified correspond to the operating conditions and one needs to take into account thermal as well as centrifugal expansion to arrive at the dimensions for manufacturing. Another problem pertained to dimensional distortion due to residual stresses arising out of welding/machining. I assisted in developing a step wise annealing schedule to reduce the distortion to the minimum.

Most of the superalloys required for the manufacture of various discs and blades were initially imported, but later MIDHANI developed all the alloys which were certified by CEMILAC, the agency for certification of materials for air-worthiness. From the designers' point of view, it was necessary to generate adequate data of the materials in use and hence a separate facility, Aeronautical Materials Testing Laboratory, was established near Midhani.

While most of the engine testing facilities was available, we had to go overseas to get some specialized testing done. Russia offered these tests at a lower cost, but procedural delays were considerable. GTRE had 5 engine test beds and it used to test the prototype only once a day. I suggested that it has to be done more number of times a day, as otherwise we may not be able to meet the project schedule. And it was done. My moment of happiness was when the first prototype of Kaveri was test run in 1994.

Kaveri was an overambitious project from the start with a very low budget compared to its equivalents, which is why, with a total of 2,839 crore spent, it was delinked from Tejas in 2008. Everyone was more or less fine with this decision. IAF said they will only order LCA in substantial numbers only if it meets their ASRs. It was supposed to use even lower compressor stages than RD33 and achieve overambition targets. In 2008 the Kaveri was able to achieve ~73 kN of thrust with AB and 49 kN of dry thrust. The Kaveri was able to achieve its dry thrust more or less; the problems start with the afterburner, where it has a shortfall. Below are the design specs of Kaveri:

Specification Value Specification Value

Power Plant For TEJAS (LCA) Engine Type Twin Spool, Low Bypass

Air Mass Flow 78 kg/sec Bypass Ratio 0.16 - 0.18

Overall Pressure Ratio 21.5 TET (Turbine Entry Temp.) 1487 - 1700 K

Max Thrust (Dry) 52 kN Max Thrust (Afterburner) 81 kN

SFC (Dry) 0.78 kg/hr/kg Max SFC with Afterburner 2.03 kg/hr/kg

Thrust-to-Weight Ratio 7.8

Kaveri also has a shortfall of around 12%, and it has produced 70-75 kN throughout its development. There are a total of 10 versions of Kaveri: from K1 to K9, K9+, or K9*. Kaveri was started with an ambitious weight target of 1000 kg. Later revised to 1100 kg for LCA and again revised to 1050 kg. The first Kaveri engine (K1) weighed 1423.78 kg. GTRE undertook weight reduction exercise starting in 1993, and the weight of K9 was 1235 kg and finally the K9+, which is 1180 kg. To further reduce the weight, the use of blisks (bladed disks), PMC ducts, which weigh 26 kg compared to metallic 32 kg, and powder metallurgy disks, which will require a high-pressure isothermal press that India does not possess as of now, we do have a 2000 MT ton isothermal forge at MIDHANI, which was used to make disks for all five stages of the high-pressure compressor of andour engines, which power the Jaguar aircrafts of the IAF. The aim of Kaveri has achieved a thrust-to-weight ratio of 6.5 against the target of 8.

The thrust and weight shortfalls are just the tip of the iceberg; Kaveri also had a fair share of other problems:

U Certain critical and crucial activities for successful development of Kaveri, viz. development of Compressor, Turbine and Engine Control System, have been lagging behind despite increase in cost by Rs 186.61 crore - CAG Report No. 16 of 2010

GTRE has been unable to freeze the design of the turbine blades, the compressor has witnessed mechanical failure in performance and the engine control system is not flight-worthy. - CAG Report No. 16 of 2010

The Kaveri engine which is designed to meet the conditions of operating fighters in the Indian environment is perhaps technologically more challenging than the airframe.

The Core Engine demonstration, which was planned for 1990, happened in 1995; Full Engine was demonstrated in 1995 instead of the planned 1992. The historical circumstances and geopolitics didn't help the program either. The LCA was to use Kaveri in the production variant while using Electric F404-GE-F2J3. In 1995, the US approved the sale of the 404 engine to India, and eleven of them were purchased to be fitted in early demonstrators of the LCA.

In 1998, after the Pokhran Tests, the US sanctioned India, all support was withdrawn, and the LCA's last hope was the Kaveri engine. In 2001, LSP-1 made its first flight at Mach 2.1 powered with an F404-F2J3. The US sanctions were lifted, and Tejas went into production with F404-IN20 engines.

The main issues with Kaveri engines were blade flutter, screeching noise, and afterburner oscillations. There were also problems with the low-pressure compressor, which is why the entire frontal section was redesigned for KDE. The problem with the fan was that of efficiency surge margin and flutter; for HPC, it was blade high-cycle fatigue failure and shortfall of performance compared to what was expected. For combustors it was pressure loss, pattern factor, and structural integrity; for afterburners it was screech, thrust boost, and buckling. At the time of writing this article, all the problems are mostly solved. The issue with afterburner instability was with the fuel spray nozzles, and mostly the afterburner was stretched.

There was also an issue of flickering, which was solved back in 2010. Another issue is the very low bypass ratio, which leaves less air for cooling. The in-house blades used by GTRE initially failed; this led GTRE to procure disks, blades, and control systems from Snecma. The major issues with Kaveri as of today are resolved. Safran did an audit on the engine a couple of times; they noticed some problems with the afterburner, and they were resolved.

13 engines are made till 2021, including 9 full prototypes (K1 to K9) and 4 core engines, all upgraded to the K9+ standard.

Two of the six Kaveri engines made in 1998 went for testing in Russia at CIMA, and a series of tests over two years were to examine its ability to withstand low pressure and temperature at high altitudes. Later in 2004, Kaveri failed high altitude testing in Russia. By 2008 Kaveri underwent 1,700 hours of ground testing in India and was sent to Russia twice. In 2011-12, Kaveri was tested in Russia by replacing one of the four engines of the Il-76 at a maximum altitude of 12 km and a forward speed of 0.7 Mach.